High Wear Resistance SS10 Tungsten Carbide Brazing Tips For Cutting Stone

Product Details:

| Place of Origin: | China |

| Brand Name: | Rixin |

| Certification: | CE ROHS UL ISO |

| Model Number: | YT5 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 5KG |

|---|---|

| Packaging Details: | Cartons |

| Delivery Time: | 7-15 days |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 50+tons+per month |

|

Detail Information |

|||

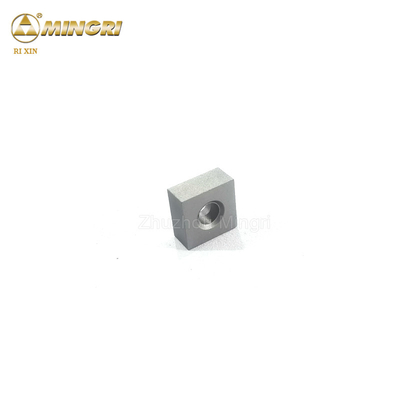

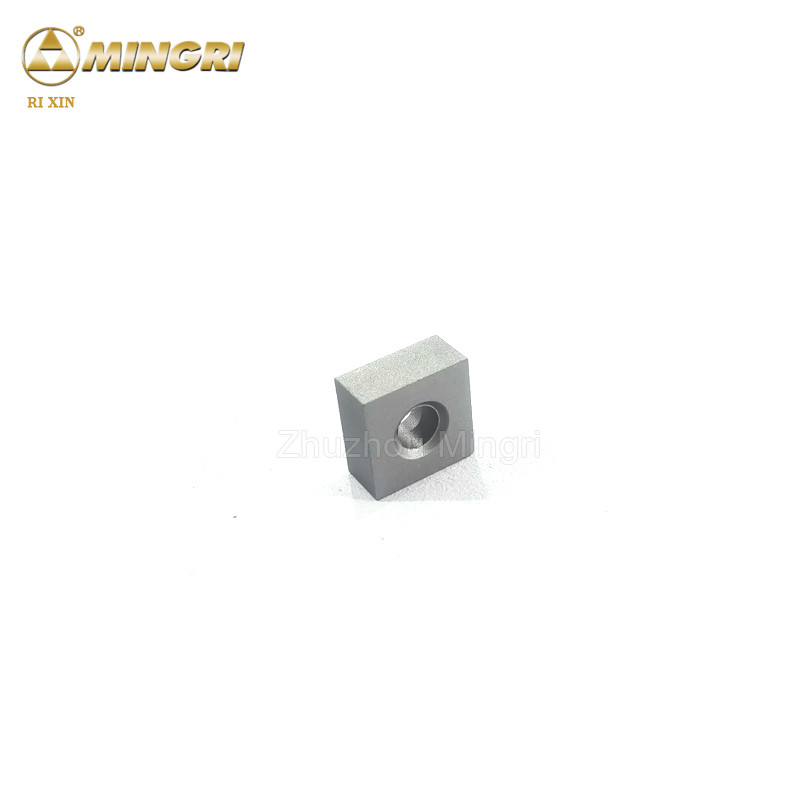

| Product Name: | Carbide Brazing Tips | Material: | Tungsten Carbide |

|---|---|---|---|

| Keyword: | SS10 Carbide Tips | Usage: | Cutting Stone |

| ODM/OEM: | Yes | Size: | 15mm * 10mm * 5mm |

| Surface: | Sand Blasting | Grade: | YG8, YG6, YT5 |

| Highlight: | SS10 Tungsten Carbide Brazing Tips,Wear Resistant Carbide Brazing Tips,Stone Cutting Carbide Brazed Tips |

||

Product Description

For Cutting Stone High Wear Resistance SS10 Tungsten Carbide Brazing Tips

Description for SS10 carbide tips

1, SS10 carbide tips to be welded onto the seats on the blades for stone cutting machines.

2, it can be used for the processing of various kinds of stones, such as limestone, sandstone, tufa stone, granite etc.

3, High quality & virgin raw material with stable properties and long working life;

4, Precision dimensions with good unit weight and size accuracy;

5, Various sizes and types for your choice;

| Grade | Density g/cm3 | Hardness HRA | T.R.S MPa | Performance&application recommend |

| YM6A | 14.85 | 92.5 | 2200 | suitable for the smei-finishing cast iron and nonferrous metals and also for the machining of manganese steel and hardened steel |

| YM6X | 14.9 | 91.5 | 2300 | suitable for the smei-finishing cast iron and nonferrous metals and also for the machining of manganese steel and hardened steel |

| YM6 | 14.95 | 90.5 | 2400 | suitable for finishing and semi-finishing of stainless and conventional alloy steel |

| YM8 | 14.7 | 89.8 | 2800 | suitable for finishing and semi-finishing of stainless and conventional alloy steel |

| YT15 | 11.4 | 91.5 | 1600 | suitable for the finishing and semi-finishing for steel and cast steel with a moderate feed rate and rather high cutting speed |

| YT5 | 12.9 | 90.5 | 2200 | suitable for the heavy cutting of steel and cast steel with a big feed rate at a medium and low speed under unfavorable working conditions |

common ss10 tips sizes are as below:

| 20*12*3.4mm |

| 20*12*3.0mm |

| 15*10*5mm |

Our advantage of SS10 carbide tips

1. 100% raw material.

6. ISO9001: 2008 certificate

2. Sintered in HIP Furnace

7. Advanced technology and equipment.

3. Size standard as per your requirements

8. Professional manufacture for 20 years

4. Professional suggestion on products

9. Advance technology and equipment.

5. Feedback within 24 hours

10. Quality Control System and strict inspection.

Packing and Shipping of SS10 carbide tips

1, we will take care of your machine packages well .

2, our worker will make sure your SS10 carbide tips clean before package.

3, add plastci foam into inner box for the whole SS10 carbide tips for sweet protection.

4, we will make export standard strong cartonn or plywood case package according to your needs.

![]()