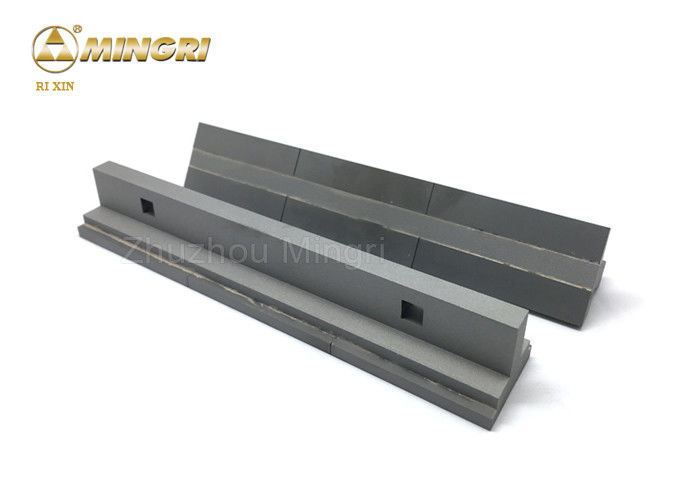

Mingri Factory Tungsten Cemented Carbide Strips Carbide Scraper For Conveyor System

Product Details:

| Place of Origin: | Zhuzhou city |

| Brand Name: | Rixin |

| Certification: | ISO 9001:2008 |

| Model Number: | as per drawing |

Payment & Shipping Terms:

| Minimum Order Quantity: | 10 |

|---|---|

| Packaging Details: | in inner box ,then into carton |

| Delivery Time: | 7-21 working days |

| Supply Ability: | 50 Tons / month |

|

Detail Information |

|||

| Product Name: | Tungsten Carbide Strip | Keyword: | Tungsten Carbide Strip |

|---|---|---|---|

| Material: | 100% Raw Material | Surface Treatment: | Sand Blasting |

| Certification: | ISO9001:2008 | Grade: | F20 |

| T.R.S: | 3500 N/MM2 | Hardness: | 91.5 HRA |

| Density: | 14.65 G/cm3 | ||

| Highlight: | tungsten carbide bar,tungsten carbide block |

||

Product Description

Mingri Factory Tungsten Cemented Carbide Strips Carbide Scraper For Conveyor System

Description of tungsten carbide strip of coveyor belt

tungsten carbide strip cleaner is mainly used for cleaning the front and back of the sticky material, debris.

Sweeper on the conveyor would have a negligible effect, coal, electricity, steel, petrochemical and other transportation equipment manufacturing enterprises rely on it to clean.

Effective cleaning function to clean the drum surface and the bottom surface of adhesive material conveyor, conveyor prevent wandering, extend the service life of the conveyor belt and accessories, to prevent accidents and so on.

| Grade | Properties | ||

| T.R.S(M/mm2) | Hardness(HRA) | Density(g/cm3) | |

| YG8 | 2800 | 89.8 | 14.7 |

| YG6 | 2400 | 90.5 | 14.9 |

| YG8C | 2600 | 88.5 | 14.7 |

|

Other grades can be offered as per customers' requirement |

|||

Advantage of tungsten carbide strip

1.Long service life due to the good performance of the tungsten carbide material.

2.welded fastening ensures optimum contact pressure of the belt and cleaning efficiency.

3.Blade lifetime is longer than polyurethane or steel material,once need to change,the

changes quickly, without use of tools

4.Can seamlessly with Flexco mechanical fasteners.

5.Optimal material path cleaning could minimizes uneven wear between the ends of the blade and center.

![]()

![]()