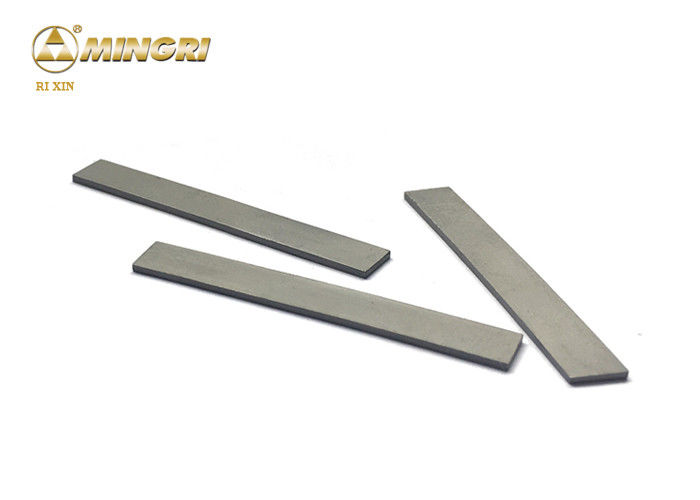

Anti - Deformation Tungsten Carbide Strips blade knife For Metal Cutting Machining

Product Details:

| Place of Origin: | China |

| Brand Name: | rixin |

| Certification: | CE,ISO9001:2015 |

| Model Number: | carbide bar |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 kg |

|---|---|

| Price: | 32-48$ /kg |

| Packaging Details: | step 1, wrapped carbide strips in plastic foam to avoid carbide strips to broke step 2, put the carbide strips in inner small carton box step 3, put the inner box into outter carton and fill the carton with foamed plastic step 4, wrap the carton with pa |

| Delivery Time: | 7-25 business days |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 50tons/month |

|

Detail Information |

|||

| Material: | Tungsten Carbide | Application: | Machining Metal |

|---|---|---|---|

| Grinding: | Coating Or Surface Polished | Size: | 100*4*2mm |

| Type: | Blanks | K1: | Carbide Strips |

| K2: | Tungsten Carbide Strips | K3: | Cemented Carbide Strips |

| Highlight: | tungsten carbide bar,tungsten carbide block |

||

Product Description

tungsten carbide strip for Metal cutting machining k30 in cutting tool industry raw mateial fine grain alloy

Grades of Metal cutting machining tungsten carbide strip

| Properties and applications of carbide for strips | ||||||||

| Grade | Density | T.R.S MPa |

Hardness HRA |

Performance & application recommended | ||||

| YM6 | 14.9 | 2150 | 90 |

Good wear resistance, used for hard wood, used for processing original wood, aluminum section bar, brass rod and cast iron. |

||||

| YM6A | 14.9 | 1860 | 92 |

Has wear resistance higher than YG6, used for processing hard wood, original wood, aluminum section bar, brass rod and cast iron. |

||||

| YM8 | 14.7 | 2320 | 89.5 |

Wear and percussion resistance , used for processing hard wood, soft wood, ferrous and non-ferrous. |

||||

| YM2T | 14.5 | 2350 | 92 |

Fine carbide, High wear resistance, high bending strength, high resistance to bonding, high thermal strength. Machining of refractory alloys, stainless steel and high manganese steel, etc. |

||||

| YM25 | 14.5 | 2150 | 92.2 |

Wear resistance and strength comparatively higher, suitable for processing cast iron, non-ferrous,metal and non-metallid materials. |

||||

|

Other grades of strips may be offered according to customers' requirement.

|

||||||||

Application of Metal cutting machining tungsten carbide strip

The application of carbide strips for woodworking cast iron cutting tool.

It can be used in many field such as woodworking, machining of refractory alloys, stainless steel, High manganese steel, for processing cast iron, non-ferrous metal and aluminum section bar, etc.

1.Superior heat stability.

2.Anti-deformation in high temperature.

3.Fine thermal shock resistance.

4.High thermal conductivity.

5.Excellent Oxidation control ability.

6.Strong anti-corrosion in high temperature.

7.Good corrosion resistance from Chemical.

8.High-wearing feature.

9.Long usage lifetime.

![]()

| Type | Unit:mm | |||||||

| Type | L | W | T | Type | L | W | T | |

| 140 * W * T | 140 | 6 | 1.5-6.0 | 230 * W * T | 230 | 8 | 2.0-6.0 | |

| 140 * W * T | 8 | 230 * W * T | 10 | |||||

| 140 * W * T | 10 | 230 * W * T | 12 | |||||

| 140 * W * T | 12 | 230 * W * T | 16 | |||||

| 140 * W * T | 14 | 230 * W * T | 18 | |||||

| 140 * W * T | 16 | 230 * W * T | 20 | |||||

| 140 * W * T | 18 | 230 * W * T | 22 | |||||

| 140 * W * T | 20 | 2.0-6.0 | 230 * W * T | 25 | 2.5-6.0 | |||

| 140 * W * T | 22 | 230 * W * T | 28 | |||||

| 140 * W * T | 25 | 230 * W * T | 30 | |||||

| 165 * W * T | 165 | 6 | 1.5-6.0 | 230 * W * T | 32 | |||

| 165 * W * T | 8 | 230 * W * T | 40 | |||||

| 165 * W * T | 10 | 320 * W * T | 320 | 8 | 2.0-6.0 | |||

| 165 * W * T | 12 | 320 * W * T | 10 | |||||

| 165 * W * T | 14 | 320 * W * T | 12 | |||||

| 165 * W * T | 16 | 320 * W * T | 14 | |||||

| 165 * W * T | 18 | 320 * W * T | 16 | |||||

| 165 * W * T | 20 | 2.0-6.0 | 320 * W * T | 18 | ||||

| 165 * W * T | 22 | 320 * W * T | 20 | |||||

| 165 * W * T | 24 | 320 * W * T | 22 | |||||

| 165 * W * T | 25 | 320 * W * T | 24 | |||||

| 165 * W * T | 26 | 320 * W * T | 25 | 2.5-6.0 | ||||

| 165 * W * T | 28 | 320 * W * T | 28 | |||||

| 165 * W * T | 30 | 2.5-6.0 | 320 * W * T | 30 | ||||

| 165 * W * T | 32 | 320 * W * T | 32 | |||||

| 165 * W * T | 35 | 320 * W * T | 35 | |||||

| 165 * W * T | 40 | 320 * W * T | 40 | |||||

| ··· | ··· | ··· | ··· | ··· | ··· | ··· | ··· | |

| Other types of strips may be offered according to customers' requirement. | ||||||||

![]()

1, Soon after the order is confirmed, carbide strip products will start to prepare the RTP powder as per customer’s requirement with our wet-grinding machine

2, Before mass production, we need to do a trial pressing and sintering using every mould, and we check the appearances and the sizes of carbide strip samples with micrometer, projectors etc. to ensure that the requirements of the drawings can be met before batch production

3, Bulk production ,press the raw materials to shape blanks,and all carbide strip blanks must be passed by semi finished inspection,

4, Then sinter blanks to finish (HIP) and finished products inspection, we have 10 sets of vacuum sintering furnace and 2 sets of HIP in the factory ensure the best quality and production capacity.

5, 1). cleaning/tumbling is to make the carbide strip look more beautiful.

2).The carbide strip can be ground according to customers’ order to a tolerance of +/-0.05

Feel free to contact me if any needs:

Whatsapp/wechat/phone:008618593402651

Facebook:Xiao Aimee

zhuzhou mingri cemented carbide co. ltd

Email:mr009@mrcarbide.com