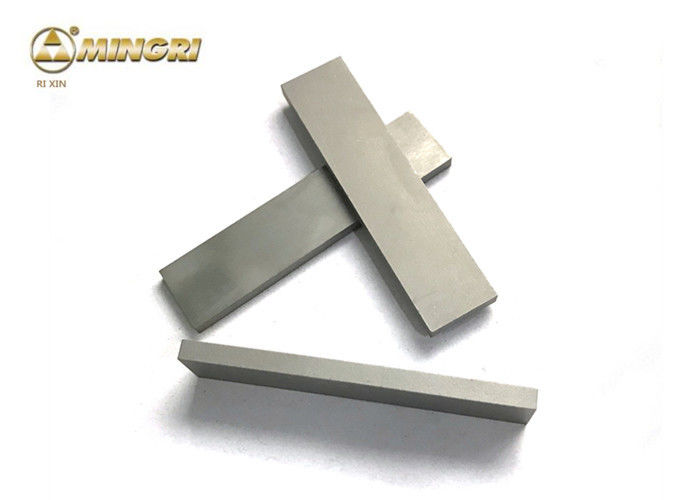

Custom Wear Resistance Tungsten Carbide Sheet Plate For Machining Refractory Alloy

Product Details:

| Place of Origin: | Zhuzhou Hu Nan China |

| Brand Name: | Rixin |

| Certification: | ISO 9001:2008 |

| Model Number: | YM11C |

Payment & Shipping Terms:

| Minimum Order Quantity: | 5KG |

|---|---|

| Price: | USD + 65~32 + 10KG ~ 50KG |

| Packaging Details: | carton |

| Delivery Time: | 5-15 days |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 50+tons+per month |

|

Detail Information |

|||

| Product Name: | Tungsten Plate Sheet | Material: | 100% Virgin Material |

|---|---|---|---|

| Density: | 14.4 | Hardness: | 87.0 HRA |

| Thickness: | 1.5-66mm | T.R.S: | 2700 MPa |

| Application: | Wear-resistant Parts | Customize: | Yes |

| Surface: | Grind | Chemiacl Composition: | Tungsten Carbide,WC And Co |

| Size: | Up To Your Requirement | ||

| Highlight: | tungsten carbide blocks,tungsten carbide wear plate |

||

Product Description

Custom Wear Resistance Tungsten Carbide Sheet Plate For Machining Refractory Alloy

Special feature of tungsten alloy plate:

1. Dimensions: 10-200mm(length), 5-200mm(width), 2-50mm(thickness)

2. Features: our tungsten carbide plates with good thermal stability, well corrosion resistance and deform resistance to high temperatures, it is excellent in thermal conductivity and antioxidant.

3. Machining cutting tools for trimming use with high wear resistance.

4. For mould making, such as stamping mould, electronic mold with good bending strength

5.For high hardness components making with good bonding resistance and thermal strength

Production Competitive Advantage of tungsten alloy plate

1) Business Type: Manufacturer, Factory.

ISO9001:2008, SGS.

2) Advanced technology, HIP sintering and precision grinding to ensure the goods performance;

3) 100% Virgin pure Raw materials;

4) Each product through the strict inspections and confirm to the requirements of the lab parameters;

5) OEM & ODM are welcomed;

6) Small order is acceptable;

7) Flexible payment terms (L/C,T/T, etc);

8) Provide custom made service with customer's drawing; Other size could be offered by your requirements;

9) We make sure to provide you with the best solutions for your individual case. Whether standard items or non-standard items all available;

10) Fast delivery and high quality;

11) Best after-sale service.![]()

| Grade | Density | Hardness | T.R.S | Performance&application recommended |

| g/cm3 | HRA | Mpa | ||

| YG6A | 14.85 | 92.5 | 2000 | Fine grain alloy,good wear resistance,it is suitable for manufacturing forming cutter,wear-resistant parts etc |

| YG8 | 14.7 | 89.8 | 2800 | High bending strength,wear resistance lower than YG6A,suitable for manufacturing forming cutter,wear-resistance part etc |

| YG11 | 14.4 | 88.5 | 2900 | |

| YG15 | 14 | 87 | 3000 | suitable for manufacturing punching dies,wear-resistant parts |

| YG20 | 13.5 | 85.5 | 2800 | High bending strength,suitable for manufacturing progressive dies and other punching dies. |

| YG13X | 14.2 | 90 | 3200 | |

| YS2T | 14.25 | 92 | 2500 | Fine grain alloy,with high wear resistance,bending strength,bonding resistance and thermal strength,it is suitable for maching refractory alloys,stainless steel,high manganese steel,etc |

Application of Cemented Carbide Plate

Mining Industry

Automotive Industry

Engineering Industry

Construction Industry

Petrochemical Industry

Customer-related Industries

Main Export Market of Tungsten carbide Products

Asia

Australasia

Central/South America

Eastern Europe

Mid East/Africa

North America

Western Europe

Company brief overview:

- Zhuzhou Mingri Tungsten Carbide Co., Ltd. was established in May of 2001 with the investment of RMB 40 million. We have up-to-date production machine line and a lot of technicians.

- Zhuzhou MingRi Cemented carbide co.,ltd is located in the tungsten carbide hometown , convenient transportation, from changsha airport just 40 minutes, wuhan just 1.5 hour, from guangzhou just 2 hours.

- A favorable peripheral environment for cemented carbide manufacturing provides a natural barrier. Convenient traffic for tomorrow's internationalization laid a wide road.

4. We specialize in various of tungsten carbide products. Our products are sold to the UK, Europe, Japan, Korea, Taiwan area and Southeast Asia.

FAQ

Q1: How to place an order?

1. Fill your Order List in our online Inquiry System.

(Also you can directly contact our salesperson by E-mail / Skype / Whats App)

2. We will make a feedback to you ASAP after receive your order list.

Q2: How we can trust your company ?

We support Aliababa trade insurance , 100% products quality protection, 100% on -time shipment protection, 100% payment protection for your covered amount.

Q3: What’s your delivery time ?

For the normal type which we have mold it takes 7-15 days after receiving the advance payment.

For the non standard which we do not have mold it takes 15-35 days after receiving the advance payment.

Yes. All products will be tested before bulk production, and we will check the physical properties, shape and tolerance for ensuring qualified products before shipping.

Q4: How to place an order?

1. Fill your Order List in our online Inquiry System.

(Also you can directly contact our salesperson by E-mail / Skype / Whats App)

2. We will make a feedback to you ASAP after receive your order list.