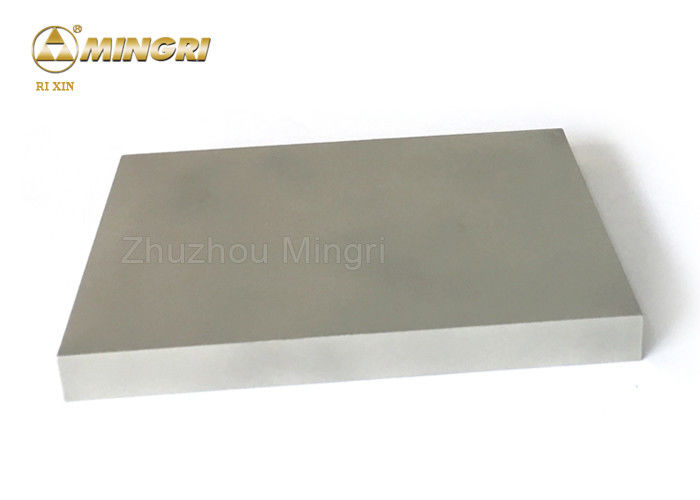

YG15 Tungsten Carbide Plate Blanks Long Lifetime Wear Parts Square Blocks Bars

Product Details:

| Place of Origin: | Zhuzhou,Hunan,China |

| Brand Name: | Ri Xin |

| Certification: | ISO9001:2015 ISO14001:2015 |

| Model Number: | As per customer request |

Payment & Shipping Terms:

| Minimum Order Quantity: | 5KG |

|---|---|

| Price: | As per technical requirements |

| Packaging Details: | First in small cartons filled with cotton, then in bigger cartons.Wood carton recommended |

| Delivery Time: | 10-20 days after receipt of payment |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union |

| Supply Ability: | 50 tons per month |

|

Detail Information |

|||

| Features: | High Hardness,good Impact-resistance | Material: | WC,Cobalt |

|---|---|---|---|

| Grades: | YG6A,YG8,YG15,YG20,YG13X,YS2T | Service: | OEM,Customized Manufacturing |

| Application: | Dies Machining,Blades Machining | Density: | 13.5-14.85g/cm³ |

| Hardness: | 85.5-92HRA | Strength: | 2000-3200 T.R.S |

| Highlight: | tungsten carbide wear plate,tungsten carbide sheet |

||

Product Description

YG15 Shock-resistance wear parts tungsten cemented carbide plates square blocks bars

Descriptions:

Tungsten Carbide Plates Features

1. 100% virgin tungsten carbide materials.

2. Sintering and ground surface.

3. Composition: WC+Co, WC+TiC+TaC+Co.

4. ISO9001:2008 vertified professional manufacturer over 19 years.

5. OEM and ODM are accepted as well.

1.Used for heat-resistant parts, wear-resistance parts, anti-shielding parts, anti-corrosion parts.

2.Used for making progressive press tools and progressive dies of high velocity ram machine.

3.Used for making connectors in electron industry, IC industry and semiconductor

4.Used for armature, stator, LED lead frame, EI silicon steel sheet and punching mould for hardware and standard parts.

| Grade | Properties & Applications | Approx Grades in China | |||

| Density | T.R.S | Hardness | |||

| g/cm3 | MPα | HRA | |||

| YM6A | 14.9 | 2000 | 92.5 | Fine grain alloy, good wear resistance. It is suitable for manufacturing forming cutter, wear-resistant parts etc. | YG6A |

| YM8 | 14.7 | 2800 | 89.8 | High bending strength, wear resistance lower than YM6A, suitable for manufacturing forming cutter, wear-resistant parts etc. | YG8 |

| YM11 | 14.4 | 2900 | 88.5 | High bending strength, wear resistance lower than YM6A, suitable for manufacturing forming cutter, wear-resistant parts etc. | YG11 |

| YM15 | 14 | 3000 | 87 | Suitable for manufacturing punching dies, wear-resistant parts. | YG15 |

| YM20 | 13.5 | 2800 | 85.5 | High bending strength, suitable for manufacturing progressive dies and other punching dies. | YG20 |

| YM13X | 14.2 | 3200 | 90.0 | High bending strength, suitable for manufacturing progressive dies and other punching dies. | YG13X |

Product types of Wear parts hard alloy widia cemented tungsten carbide board block bar plates

Size and Tolerance:

| L(mm) | W(mm) | H(mm) |

| 100 | 100 | 1.5~70 |

| 105 | 105 | 1.5~70 |

| 110 | 110 | 1.5~70 |

| 120 | 120 | 1.5~70 |

| 150 | 150 | 1.5~70 |

| 200 | 200 | 1.5~70 |

| 250 | 250 | 1.5~70 |

| 300 | 300 | 1.5~70 |

![]() All the products must be inspected strictly with the ultrasonic and only those haven't any harm such as pore can be shipped out. High density, high wear & impact resistance, which lead them a long lifetime.

All the products must be inspected strictly with the ultrasonic and only those haven't any harm such as pore can be shipped out. High density, high wear & impact resistance, which lead them a long lifetime.

Product Description of High density hard alloy wear resistant cemented tungsten carbide plates

---- Making connectors in electron industry, IC industry and semiconductor

---- Heat-resistant parts, wear-resistance parts, anti-shielding parts, anti-corrosion parts.

---- Making progressive press tools and progressive dies of high velocity ram machine.

---- Armature, stator, LED lead frame, EI silicon steel sheet and punching mould for hardware and standard parts.

Our advantages:

1.Strong R&D team. Professional engineers serve for clients, recommend product and grades as per your applications. We also offer after-sale service.

2. Strong Mould R&D team. We support product customization as per your requirements, ensure high working efficiency and product quality.

3. Successful cooperation case: We cooperate with clients in domestic and abroad, and get good feedback from them.

Feel free to contact me if any needs:

Whatsapp/wechat/phone:008618593402651

Facebook:Xiao Aimee

zhuzhou mingri cemented carbide co. ltd

Email:mr009@mrcarbide.com