Grinding YM15C 15% carbide sqare parts bit/tips With Homogeneous Property

Product Details:

| Place of Origin: | Hu Nan China |

| Brand Name: | Rixin |

| Certification: | ISO 9001:2008 |

| Model Number: | YM15C |

Payment & Shipping Terms:

| Minimum Order Quantity: | 5KG |

|---|---|

| Price: | usd + 65~32 + 10kg~50kg |

| Packaging Details: | carton |

| Delivery Time: | 5-15 days |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 50+tons+per month |

|

Detail Information |

|||

| Product Name: | Carbide Sqare Parts Tips | Material: | 100% Raw Material |

|---|---|---|---|

| Density: | 14.0 | Hardness: | 86.0HRA |

| Thickness: | 1.5-66mm | T.R.S: | 3100 MPa |

| Application: | Wear-resistant Parts | Keywords: | Carbide Sqare Parts Tips |

| Finish: | Griding, Blank | Usage: | Mould, Cutting |

| Highlight: | tungsten carbide blocks,tungsten carbide sheet |

||

Product Description

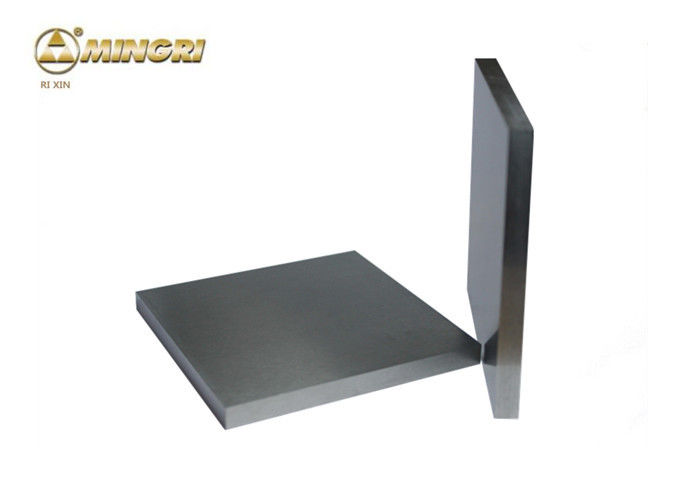

Grinding YM15C 15% carbide sqare parts bit/tips With Homogeneous Property

Specification of carbide sqare parts tips

Tungsten carbide button/rod/tips fitting could mine quarrying coal-cutting, road construction, snow plow etc. It is fitting for serving as drill heads of heavy rock-digging machines, plumbun heads are used in deep hole drilling terrace vehicles. We can provide all kinds of buttons according to the drawings and samples including non-standard styles.

| L | W | S |

| 200 | 200 | 15-45 |

| 150 | 150 | 15-45 |

| 150 | 100 | 15-45 |

| 150 | 130 | 15-45 |

| 150 | 80 | 15-45 |

| 120 | 120 | 15-45 |

| 100 | 100 | 15-50 |

| 100 | 50 | 15-50 |

| 100 | 45 | 15-50 |

| 80 | 55 | 10-50 |

| 80 | 40 | 10-50 |

| ... | ... | ... |

Production Process of carbide sqare parts tips

1. The manufacturing process begins with the composition of a specific tungsten carbide powder mixture- tailored for the application.

2. This powder is compacted into a form.

3. In a high- temperature sintering furnace, the tungsten carbide structure of the blank is shaped at precise temperatures for strictly defined periods.

4. During this heat treatment, the tungsten carbide blank undergoes shrinkage of some 50% in volume.

5. The sintered tungsten carbide component gains its final finish by additional grinding, lapping and/ or polishing processes.

![]()

Grade introduction of carbide sqare parts tips

| Grades | ISO Grade | Chemical Composition |

Density (g/cm3) | HRA | T.R.S (N/mm2) |

| YG4C | 96%WC, 4%Co | 15.00 | 89.5 | 1800 | |

| YG6 | K20 | 94%WC, 6%Co | 14.80 | 89.5 | 1700 |

| YG8 | K20-K30 | 92%WC, 8%Co | 14.70 | 88.5 | 2300 |

| YG8C | K30 | 92%WC, coarse | 14.70 | 88.0 | 2300 |

| YG9C | YK20 | 94%WC, 6%Co | 14.45 | 87.0 | 2400 |

| YG11C | 89%WC, 11%Co | 14.40 | 86.5 | 2450 | |

| YG13C | 87%WC, 13%Co | 14.30 | 86.0 | 2500 | |

| YG15 | K40 | 85%WC, 15%Co | 14.00 | 86.5 | 2500 |

| YG16 | 84%WC, 16%Co | 14.10-14.30 | 87.5 | 2400 | |

| YG20 | 80%WC, 20%Co | 13.40-13.70 | 85.0 | 2254 |

Company brief overview:

1 Zhuzhou Mingri Tungsten Carbide Co., Ltd. was established in May of 2001 with the investment of RMB 40 million. We have up-to-date production machine line and a lot of technicians.

2 Zhuzhou MingRi Cemented carbide co.,ltd is located in the tungsten carbide hometown , convenient transportation, from changsha airport just 40 minutes, wuhan just 1.5 hour, from guangzhou just 2 hours.

3 A favorable peripheral environment for cemented carbide manufacturing provides a natural barrier. Convenient traffic for tomorrow's internationalization laid a wide road.

![]()

4 We specialize in various of tungsten carbide products. Our products are sold to the UK, Europe, Japan, Korea, Taiwan area and Southeast Asia.