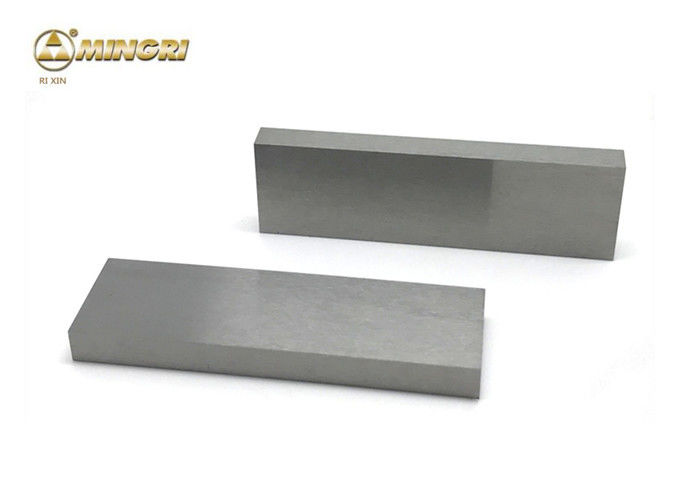

industry tool necessity Rectangle tungsten carbide mould cutting parts

Product Details:

| Place of Origin: | Hu Nan China |

| Brand Name: | Rixin |

| Certification: | ISO 9001:2008 |

| Model Number: | YM8 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 5KG |

|---|---|

| Price: | USD + 65~32 + 10KG~ 65KG |

| Packaging Details: | carton |

| Delivery Time: | 5-15 days |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 50+tons+per month |

|

Detail Information |

|||

| Product Name: | Tungsten Carbide Mould | Material: | 100% Raw Material |

|---|---|---|---|

| Density: | 14.7 | Hardness: | 89.8HRA |

| Thickness: | 1.5-66mm | T.R.S: | 2800 MPa |

| Application: | Wear-resistant Parts | Customize: | Yes |

| Finish: | Blank/polish/ground | Keywords: | Tungsten Carbide Mould |

| Highlight: | tungsten carbide wear plate,tungsten carbide sheet |

||

Product Description

industry tool necessity Rectangle tungsten carbide mould cutting parts

Specification of tungsten carbide mould

1. Material: 100% virgin raw material with fine grain size;

2. Grade: Various grades for choice;

3. High wear resistance, high hardness and impact toughness;

4. Advanced technology , automatic pressing , HIP sintering and precision grinding;

5. Having very good mechanical &chemical stability;

6. High quality & reasonable price & fast delivery & best service

| L | W | S |

| 200 | 200 | 15-45 |

| 150 | 150 | 15-45 |

| 150 | 100 | 15-45 |

| 150 | 130 | 15-45 |

| 150 | 80 | 15-45 |

| 120 | 120 | 15-45 |

| 100 | 100 | 15-50 |

| 100 | 50 | 15-50 |

| 100 | 45 | 15-50 |

| 80 | 55 | 10-50 |

| 80 | 40 | 10-50 |

| ... | ... | ... |

Production Process of tungsten carbide mould

1. The manufacturing process begins with the composition of a specific tungsten carbide powder mixture- tailored for the application.

2. This powder is compacted into a form.

3. In a high- temperature sintering furnace, the tungsten carbide structure of the blank is shaped at precise temperatures for strictly defined periods.

4. During this heat treatment, the tungsten carbide blank undergoes shrinkage of some 50% in volume.

5. The sintered tungsten carbide component gains its final finish by additional grinding, lapping and/ or polishing processes.

![]()

Grade introduction of tungsten carbide mould

| Grade | Density | Hardness | T.R.S | Performance&application recommended |

| g/cm3 | HRA | Mpa | ||

| YG6A | 14.85 | 92.5 | 2000 | Fine grain alloy,good wear resistance,it is suitable for manufacturing forming cutter,wear-resistant parts etc |

| YG8 | 14.7 | 89.8 | 2800 | High bending strength,wear resistance lower than YG6A,suitable for manufacturing forming cutter,wear-resistance part etc |

| YG11 | 14.4 | 88.5 | 2900 | |

| YG15 | 14 | 87 | 3000 | suitable for manufacturing punching dies,wear-resistant parts |

| YG20 | 13.5 | 85.5 | 2800 | High bending strength,suitable for manufacturing progressive dies and other punching dies. |

| YG13X | 14.2 | 90 | 3200 | |

| YS2T | 14.25 | 92 | 2500 | Fine grain alloy,with high wear resistance,bending strength,bonding resistance and thermal strength,it is suitable for maching refractory alloys,stainless steel,high manganese steel,etc |

Company brief overview:

1 Zhuzhou Mingri Tungsten Carbide Co., Ltd. was established in May of 2001 with the investment of RMB 40 million. We have up-to-date production machine line and a lot of technicians.

2 Zhuzhou MingRi Cemented carbide co.,ltd is located in the tungsten carbide hometown , convenient transportation, from changsha airport just 40 minutes, wuhan just 1.5 hour, from guangzhou just 2 hours.

3 A favorable peripheral environment for cemented carbide manufacturing provides a natural barrier. Convenient traffic for tomorrow's internationalization laid a wide road.

![]()

4 We specialize in various of tungsten carbide products. Our products are sold to the UK, Europe, Japan, Korea, Taiwan area and Southeast Asia.