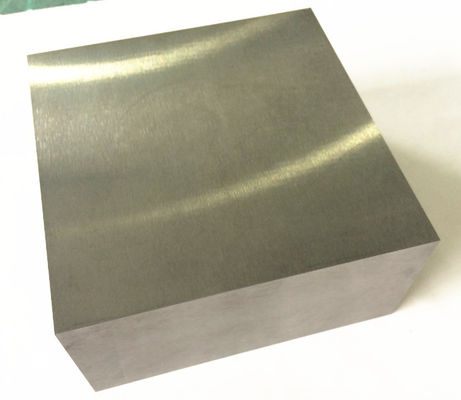

Tungsten Carbide Plate , Cemented Carbide Plate,YG6A ,YG8,WC,Cobalt

Product Details:

| Place of Origin: | China |

| Brand Name: | RI XIN |

| Certification: | ISO14001,ISO9001 |

| Model Number: | YG6A ,YG8,YG11,YG15,YG20,YG13X,YS2T |

Payment & Shipping Terms:

| Minimum Order Quantity: | 10KG |

|---|---|

| Price: | Price varies according to the grade,weight and size |

| Packaging Details: | First in small cartons filled with cotton, then in bigger cartons.Or wood carton recommended. |

| Delivery Time: | 7-20 Days |

| Payment Terms: | T/T, L/C |

| Supply Ability: | 50 Tons per month |

|

Detail Information |

|||

| Features: | HIP Sintering,Good Wear Resistance,High Bending Strength | Component: | WC,Cobalt |

|---|---|---|---|

| Service: | OEM,ODM | Grade: | YG6A ,YG8,YG11,YG15,YG20,YG13X,YS2T |

| Finish: | Polished,Sand-blasted | Products: | Blank,virgin Or Deep Processed |

| Application: | Manufacturing Forming Cutter,Metal-cutting Tools,machining Cast Iron,stainless Steel And Brass Rod Or Used For Punching Dies,wear Resistant Parts And Etc. | ||

| Highlight: | tungsten carbide blocks,tungsten carbide sheet |

||

Product Description

Description:

- Take HIP sintering, Very good wear resistance,good impact resistance,high bending strength,high bonding resistance.

- Widely used for punching dies,wear resistantance parts,manufacturing progressive dies,machining refractory alloys,stainless steel.

- OEM and ODM services available.

Grades and applications:

| Grade |

Density g/cm³ |

T.R.S Mpα |

Hardness HRA |

Performance and application |

| YG6A | 14.9 | 1850 | 92.0 |

Fine grain carbide, with good wear resistance, used for processing blades, wear resistant parts etc. |

| YG8 | 14.7 | 2400 | 89.5 |

High bending strength, used for processing blades, wear resistant parts etc. |

| YG15 | 14.5 | 2500 | 87.5 | Used for punching dies, stamping dies and wear resistant parts. |

| YG20 | 13.5 | 2800 | 85.5 | High bending strength, used for step dies and other stamping dies. |

| YS2T | 14.5 | 2350 | 92.0 |

Fine grain carbide, high wear resistance, high bending strength, high thermal strength. Machining of refractory alloys, stainless steel and high manganese steel etc. |

Our advantages:

1.Strong R&D team. Professional engineers serve for clients, recommend product and grades as per your applications. We also offer after-sale service.

2.Strong Mould R&D team. We support customization of products as per requirements, ensure high working efficiency and product quality.

3.Successful cooperation case: We cooperate with clients in domestic and abroad, and get good feedback from them.

![]()

![]()

![]()

![]()

![]()

![]()