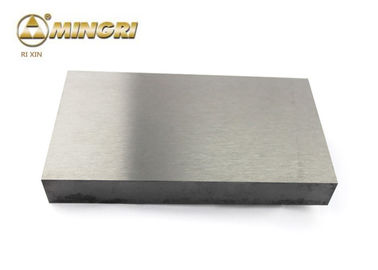

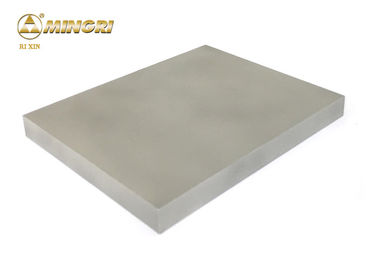

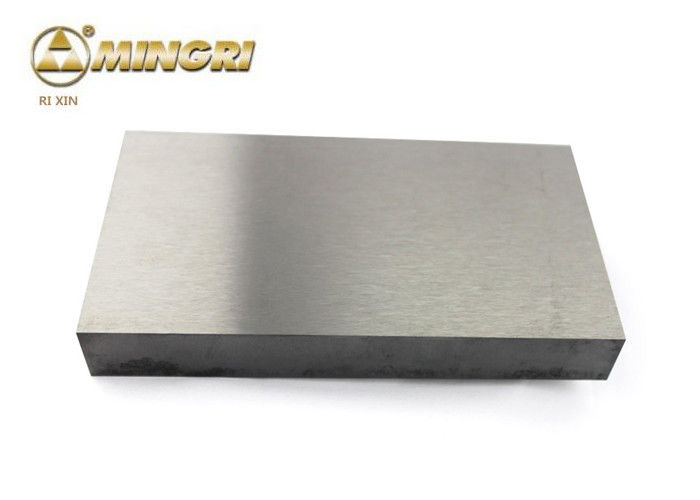

High Impact Resistance YG8 flat Tungsten Carbide Plate / sheet / bar / block

Product Details:

| Place of Origin: | China |

| Brand Name: | Rixin |

| Certification: | CE ROHS UL ISO |

| Model Number: | YG8 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 5KG |

|---|---|

| Price: | USD + 32~65 + KG |

| Packaging Details: | Cartons |

| Delivery Time: | 7-20 days |

| Supply Ability: | 50+Tons+per month |

|

Detail Information |

|||

| Product Name: | Tungsten Carbide Plate | Material: | Cemented Carbide |

|---|---|---|---|

| Original Place: | Zhuzhou | Dimensions: | As Per Client's Drawing |

| Shape: | Customized | Grades: | YG8 |

| Key Word: | Flat Thread Rolling Dies | ||

| Highlight: | tungsten carbide blocks,tungsten carbide wear plate |

||

Product Description

High Impact Resistance YG8 flat Tungsten Carbide Plate / sheet / bar / block

Specification of Tungsten Carbide Plate / sheet / bar / block

1.YG6A YG8 YM15 YM20 YM2T grades are for your chioce.

2.OEM/ODM accepted.

3.Samples available.

4.100% virgin materials.

5.Factory price.

Description of Tungsten Carbide Plate / sheet / bar / block

Tungsten carbide plates are used for cutting metal, wood and other materials. The advantages of our carbide cutting plates are smooth, fast cutting speed. Unlimited tracks of grades and sizes of carbide plates are available in our company.

We produce tungsten plates in different sizes and qualities. We accept orders of all Types of special products designed for our customers.

| Grade |

Density G/cm |

Hardned HAR |

TRS | Performance&application recommended |

| YG3 | 15.30 | 92.5 | 1700 | Superior wear resistance only less than YG3X, sensitive to impact and vibration, suitable for cast non-ferrous metal and its alloy finish turning, semi-finish turning, thread finish turning and hole expanding. |

| YG3X | 15.30 | 93.6 | 1450 | Best wear resistance in Tungeten and Cobalt alooy, but not good in anti-impact proprety, suitable for cast iron, non-ferrous and alloy, quenched steel, alloy steel small cutting section machining at high speed. |

| YG6X | 14.85 | 92.4 | 2000 | Belong to small granule Tungsten carbide alloy, wear resistance higher than YG6. Suitable for machining cold and hard alloy cast iron and heat resistance alloy steel, as well as finish machiing for normal cast iron. |

| YG6 | 14.85 | 91.1 | 2100 | High wear resistance but less than YG3, better anti-impact and anti-vibration than YG3X, Suitable for cast iron, non-ferrous and alloy, non-metal material semi-finish machining and finish machining. |

| YM6A | 14.9 | 92.0 | 1850 | fine grade alloy, with good wear resistance, used for processing blades,wear resistance parts etc. |

| YM8 | 14.7 | 89.5 | 2400 | High bending strength, wear resistance lower than MK6A, used for processing blades,wear resistance parts etc. |

| YM15 | 14.5 | 87.5 | 2500 | Used for punch dies,stamping dies and wear resistance parts. |

| YM20 | 13.5 | 85.5 | 2800 | High bending strength,used for step dies and other stampings dies. |

| YM2T | 14.5 | 92.0 | 2350 | Fine carbide, High wear resistance, high bending strength, high resistance to bonding, high thermal strength. Machining of refractory alloys,stainless steel and high manganese steel, etc. |

![]()

Advantages of Tungsten Carbide Plate / sheet / bar / block

1. We offer a various of dimensions for tungsten carbide plate, and we also produce tungsten carbides in various grades and surface conditions.

2. The carbide board can also be specially designed according to customers’ design. with over 1 years of manufacturing experience.

3. Before shipping out, all the products must be inspected strictly with the ultrasonic.

4. High density,high wear and impact resistance lead them a long lifetime.

5. There are some senior engineers who have specialized in tungsten carbid area for over years.

Production of tungsten carbide plate / sheet / bar / block

1, make raw material, when we received and confirmed customer orders, we sill start to grind, dry, screen raw material to make powder.

2, after production raw material, we will start to manual press into shape by manual machine.

3, semi products inspection, check every carbide plate if has hole,broke,laminating ect

4, after inspection, then we will put carbide plate into sintering furnance to sinter, carbide plate blanks will reach high wear resistance and strength through high temperature sintering.

5, grinding and surface treatment, if customer has tolerance requirement, we will grind carbide plate blanks, then clean surface and sand blast.

![]()

Company brief overview

Zhuzhou Mingri Cemented Carbide Co., Ltd was established in 2001 with strong team service. We own up-to-date production line, advanced equipment, and technicians.

We specialize in cold forging die cores, brazed tips, disc cutters, plates and boards, saw tips, round rods, rock drilling bits and buttons, milling tools, geological exploration drill tool, etc.

Mingri has been awarded ISO9001:2008 and ISO14001Environment Management Certificates.

Our main overseas markets:

1.Europe,UK, North Europe, Russia,

2.Latin America, Brazil, America,

3.South Asia, India, South-east Asia, Japan, Taiwan, etc.

![]()

Contact us

![]()

More products for you choosing

![]()

![]()

![]()