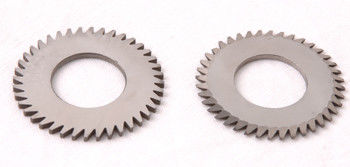

Excellent Carbide Disc Cutter

Product Details:

| Place of Origin: | Zhuzhou Hunan China |

| Brand Name: | none |

| Certification: | ISO9001:2008 ISO14001:2004 |

| Model Number: | Φ12~250mm x 2~4.5mm |

Payment & Shipping Terms:

| Minimum Order Quantity: | 10 pcs |

|---|---|

| Packaging Details: | Packed in carton firstly, and then reinforced with wooden or paper case for outer packing |

| Delivery Time: | 10-15 working days after received your payment |

| Supply Ability: | 30000 PCS |

|

Detail Information |

|||

| Product Name: | Cemented Carbide Disc Cutter | Surface: | Unground Or Grinding |

|---|---|---|---|

| Grade: | YL10.2 | Grain Size: | Fine |

| Highlight: | tungsten carbide blade,tungsten carbide saw blade |

||

Product Description

Excellent performance cemented carbide cutter disc/carbide disc cutter

Description:

1. good wear resistance, small grinding force, low grinding temperature and good quality of processing

2. special cutting instrument which utilizes abrasive powders and high speed, vibratory motion to cut discs, holes, cylinders, squares and other shapes from hard, brittle materials.

3. widely used to cut paper, tile, tobacco, PCB board, aluminum, stainless steel, copper and other metals

Applications:

For slotting in the spectacles frame's industry;

For computer hard disk head industry;

For cutting/scoring the pcb board;

For artificial crystal slotting/cutting;

For jewellery (gold, silver, copper), accessory industry;

For metal (alloy) precise cutting/slotting;

Grade and Applications:

<

| Grade |

Density g/cm3 |

T.R.S MPα |

HRA | Properties & Applications |

Approx Grades in China |

ISO |

| SH6A | 14.9 | 1850 | 92 |

Fine grain alloy, good wear resistance. It is suitable for semifinishing the chilled cast iron, nonferrous metal and its alloy. It is also suitable for semifinishing and finishing the hardened steel and alloy steel. |

YG6A | K10 |

| SH10A | 14.8 | 2450 | 90.5 |

High wear resistance and bending strength, suitable for disc cutters in electronics industry. |

_ | K20-K30 |

| SH25 | 14.8 | 2200 | 89.5 |

Higher strength, impact and shock resistance than SH6A, but lower in wear resistance and cutting speed. It is suitable for rough machiningcast iron, nonferrous metal and its alloy as well as non metallic materials at low cutting speed. |

YG8 | K20 |

| SH30 | 14.7 | 2320 | 89.5 |

Higher strength, impact and shock resistance than SH25, but lower in wear resistance and cutting speed. It is suitable for rough machining cast iron, nonferrous metal and its alloy as well as non metallic materials at low cutting speed. |

YG8 | K20 |

| SH35 | 14.5 | 2200 | 91 |

Fine grain alloy, with good wear resistance. It is suitable for machining hard wood, plywood,PCB, PVC and metals. |

YG10X | K10-K20 |

| SH40 | 14.5 | 2480 | 92 |

Fine grade alloy, with high wear resistance, bending strength, bonding resistance and thermal strength. It is suitable for machining plywood, PCB, PVC, refractory alloys, stainless steel and high manganese steel, etc. |

YS2T | K10-K20 |

| SH50 | 14.3 | 2420 | 90 |

Moderate wear resistance and bending strength, suitable for machining steel alloy etc. |

_ |

K20-K30

|

Size and drawing:

![]()

![]()

<

| TYPE | D | d | S |

| Φ12×Φ6×S | 12 | 6 | 0.6-4.5 |

| Φ13×Φ6×S | 13 | 6 | 0.6-4.5 |

| Φ16×Φ6×S | 16 | 6 | 0.6-4.5 |

| Φ22×Φ10×S | 22 | 10 | 0.6-4.5 |

| Φ25×Φ12×S | 25 | 12 | 0.6-5.5 |

| Φ32×Φ10×S | 32 | 10 | 0.8-5.5 |

| Φ40×Φ10×S | 40 | 10 | 0.8-6.0 |

| Φ45×Φ13×S | 45 | 13 | 0.8-6.0 |

| Φ53×Φ13×S | 53 | 13 | 0.8-6.0 |

| Φ52×Φ24.5×S | 52 | 24.5 | 0.8-6.0 |

| Φ53×Φ24.5×S | 53 | 24.5 | 0.8-6.0 |

| Φ55×Φ16×S | 55 | 16 | 0.8-6.0 |

| Φ58×Φ22×S | 58 | 22 | 0.8-6.0 |

| Φ60×Φ19×S | 60 | 19 | 0.8-7.0 |

| Φ63×Φ17×S | 63 | 17 | 0.8-7.0 |

| Φ70×Φ22×S | 70 | 22 | 0.8-7.0 |

| Φ75×Φ22×S | 75 | 22 | 0.8-7.0 |

| Φ80×Φ22×S | 80 | 22 | 0.8-7.0 |

| Φ83×Φ21×S | 83 | 21 | 0.8-7.0 |

| Φ86.5×Φ21.5×S | 86.5 | 21.5 | 1.0-7.0 |

| Φ90×Φ22×S | 90 | 22 | 1.0-7.0 |

| Φ100×Φ22×S | 100 | 22 | 1.0-7.0 |

| Φ125×Φ22×S | 125 | 22 | 1.0-7.0 |

| Φ200×Φ70×S | 200 | 70 | 3.0-4.5 |

| Φ250×Φ70×S | 250 | 70 | 3.0-4.5 |

| Φ250×Φ95×S | 250 | 95 | 3.0-4.5 |