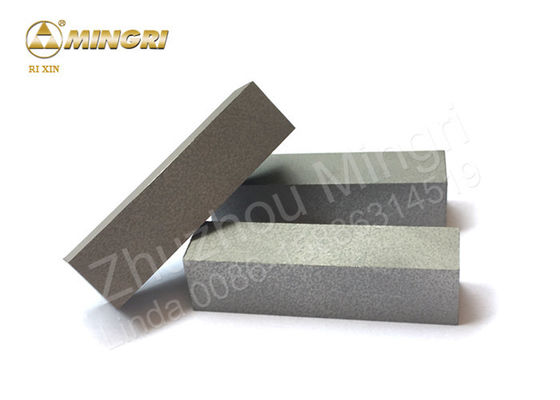

YS2T / YL10.2 Tungsten Carbide Strips , Tungsten Carbide Production for cutting tools

Product Details:

| Place of Origin: | Zhuzhou Hunan China |

| Brand Name: | none |

| Certification: | ISO9001:2008 ISO9001:14001 |

| Model Number: | many |

Payment & Shipping Terms:

| Minimum Order Quantity: | 5KG |

|---|---|

| Packaging Details: | plastic box, brown paper box, wooden case |

| Delivery Time: | 2-3 weeks |

| Supply Ability: | 20 tons/month |

|

Detail Information |

|||

| Product Name: | Cemented Carbide Strips | Application: | Cutting Wooden And Metal |

|---|---|---|---|

| Type: | Various | Matierial: | Tungsten Carbide |

| Alloy Specification: | Many | Chemical Composition: | WC+CO |

| Shape: | Square | ||

| Highlight: | tungsten carbide block,tungsten carbide plate |

||

Product Description

YS2T / YL10.2 Tungsten Carbide Strips , Tungsten Carbide Production for cutting tools

a×b×L |

a (mm) |

b (mm) |

L (mm) |

a×b×L |

a (mm) |

b (mm) |

L (mm) |

| 3~8+0.2+0.4 | 1~3+0.15+0.35 | 330+0+3.0 | 14~34+0.4+0.6 | 2~5+0.15+0.35 | 330+0+3.0 | ||

| 8~14+0.3+0.5 | 2~5+0.15+0.35 | 330+0+3.0 |

Note: Product can be customized. The data sheet is for your reference.

Common grades for cemented carbide strips:

| Grade |

Density g/cm³ |

TRS |

Hardness HRA |

Performance & application | Approx ISO grade |

| YG6 | 14.9 | 2150 | 90 | Good wear resisitance, used for cutting hard wood, original wood, aluminum section bar, brass and cast iron. | K10 |

| YG6A | 14.9 | 1860 | 92 | Wear resistance even higher than YG6, used for cutting hard wood, original wood, aluminum section bar, brass and cast iron. | K10 |

| YG8 | 14.7 | 2320 | 89.5 | High wear resistance and percussion resistance. Used for processing hard wood, soft wood, ferrous and non-ferrous metal. | K20 |

| YS2T | 14.5 | 2350 | 92 | Fine grain sized carbide. High wear resistance, high bending strength, high thermal strength. Used for machining refractory alloys, stainless steel and high manganese steel etc. | |

| YS25 | 13.0 | 2200 | 91 | Suitable for processing cast iron, non-ferrous metal and non-metallid materials. | |

| YG10X | 14.5 | 2150 | 92.2 | Suitable for processing cast iron, non-ferrous metal and non-metallid materials | K20 |

Description:

Tungsten carbide strip is available for different grinding geometric parameters and suitable for both cutting materials and nonmetal materials, also it can be applied to conventional,carbide inserts, semi-automatic lathe, automatic lathe and planning machine to work grooves and operate cutting, etc.We can customize different types of tungsten carbide strips.

Applications:

Carbide strip is widely used for general wood cutters / hard wood cutters, plastic and tobacco cutting.

And it is suitable for the production of various types of motors, electronic progressive dies punches.

Tungsten Carbide - Main Property:

- Excellent Hardness: 86~93 HRA, which equal to 68~81HRC;

- Excellent hot working performance: Hardness could be remained at 60 HRC under 900~1000 ℃

- Excellent wear resistance;

- High cutting speed;

- Long service life

![]()