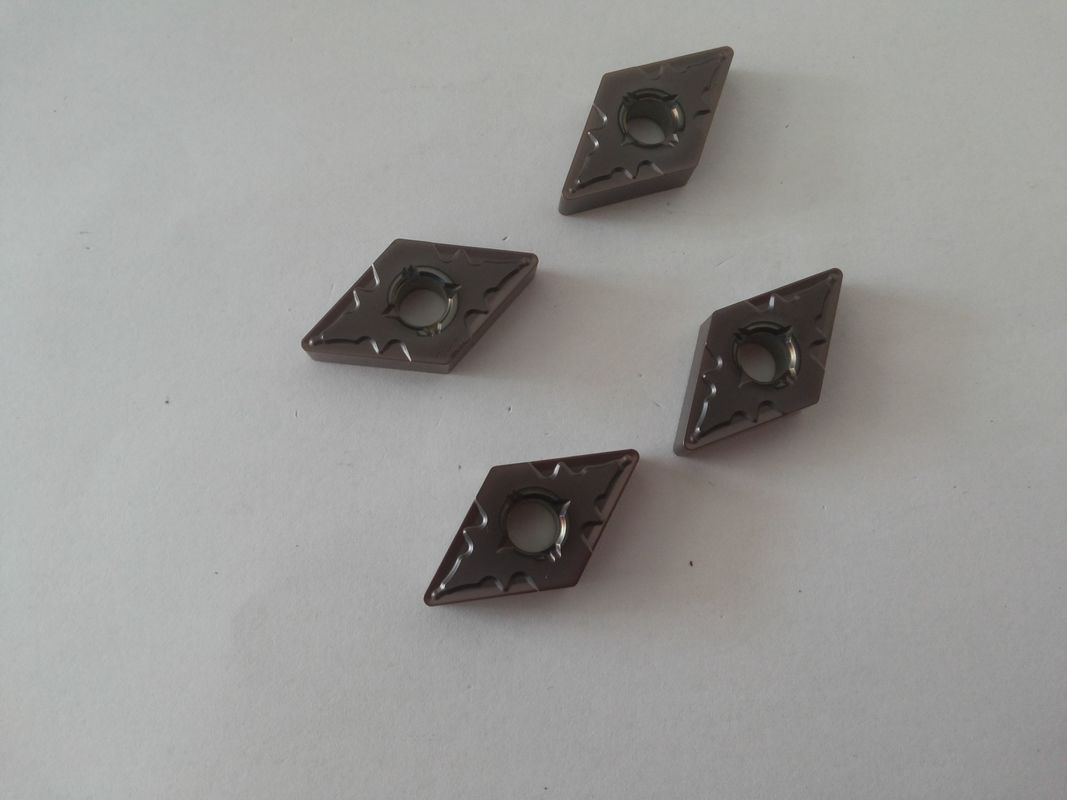

YBC151 Carbide Cutter Inserts cemented carbide cutting tools milling insert

Product Details:

| Place of Origin: | Zhuzhou Hunan |

| Brand Name: | none |

| Certification: | ISO9001:2004 ISO14001:2004 |

| Model Number: | many |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100 pcs |

|---|---|

| Packaging Details: | solid cnc milling insert knife cnmg packing :10 pieces / box or as your request |

| Delivery Time: | 10-15 days |

| Supply Ability: | 10000 pcs |

|

Detail Information |

|||

| Type: | Power Tool Parts | Belong To: | Cutting Tool |

|---|---|---|---|

| Grade: | P10,P20,P30 | Using For: | Cutting Steel, Stainless Steel, Cast Iron |

| Highlight: | cemented carbide inserts,carbide milling inserts |

||

Product Description

Carbide Cutter Inserts cemented carbide cutting tools milling insert

Features of solid carbide milling insert

1. It uses special grade ultrafine particles tungsten carbide powder as raw material. Soface milling inserts matrix has excellent strength and hardness indication.

2. With special coating process which obtained the national patent technology, the face milling blade surface is pretty smooth, while keeps milling blade toughness and hardness.

3. The unique grooving design makes the milling blade edge more sharp, so the cutting efficiency was improved 30% or more.

Data sheets of solid carbide milling insert

| Note: Product can be customized, OEM/ODM is avaliable. The data sheet is for your referance. |

|

| YBC151 | High wear resistance of the matrix and MT-TiCN, thick Al2O3 and TiN coating. |

| YBC152 | Thick TiCN and Al2O3 coating |

| YBG102 | nc-TiAN coating and fine-grained matrix. |

| YBG202 | nc-TiAN coating and fine-grained matrix. |

| YBG205 | Added abrasion resistance and high temperature rare elements ultrafine TiAlN based nano-coating. High layer hardness and excellent resistance to high temperature provide effective protection for the cutting edge. |

| YBM151 | Special organizational structure and TiCN, thin Al2O3 and TiN coating. |

| YBM251 | Good toughness and strength matrix and TiCN, thin Al2O3 and TiN coating. |

| YBM253 | With the advance extra fine grain nanometer coating technology, match up with the high toughness gradient matrix. |

Our advantages:

1. Use 100% tungsten carbide raw material

2. ISO 9001:2008 ISO 14001:2004 Certification

3. With eighteen years’ experience

4. Advanced technology , automatic pressing , HIP sintering

5. The tolerance of polish and ground can be +0.005/-0.005m

We can produce solid cnc milling insert knife cnmg with different size and specification.

6. OEM/ODM is acceptable. Welcome to share your ideas.

Application

For cast iron, steel and some other high hardness metal.

Zhuzhou Mingri Cemented Carbide Co., Ltd. produce an extensive range of tungsten carbide grades inhouse including the popular ISO application grades of K05,K10,K20,K30,K40,P10,P20 & P30/40, as well as numerous special Cobalt and also Nickel binder tungsten carbide grades for use in corrosine resistant applictions.

Our production are exported to UK, European, Japan, Taiwan and South-east Asia etc.

![]()