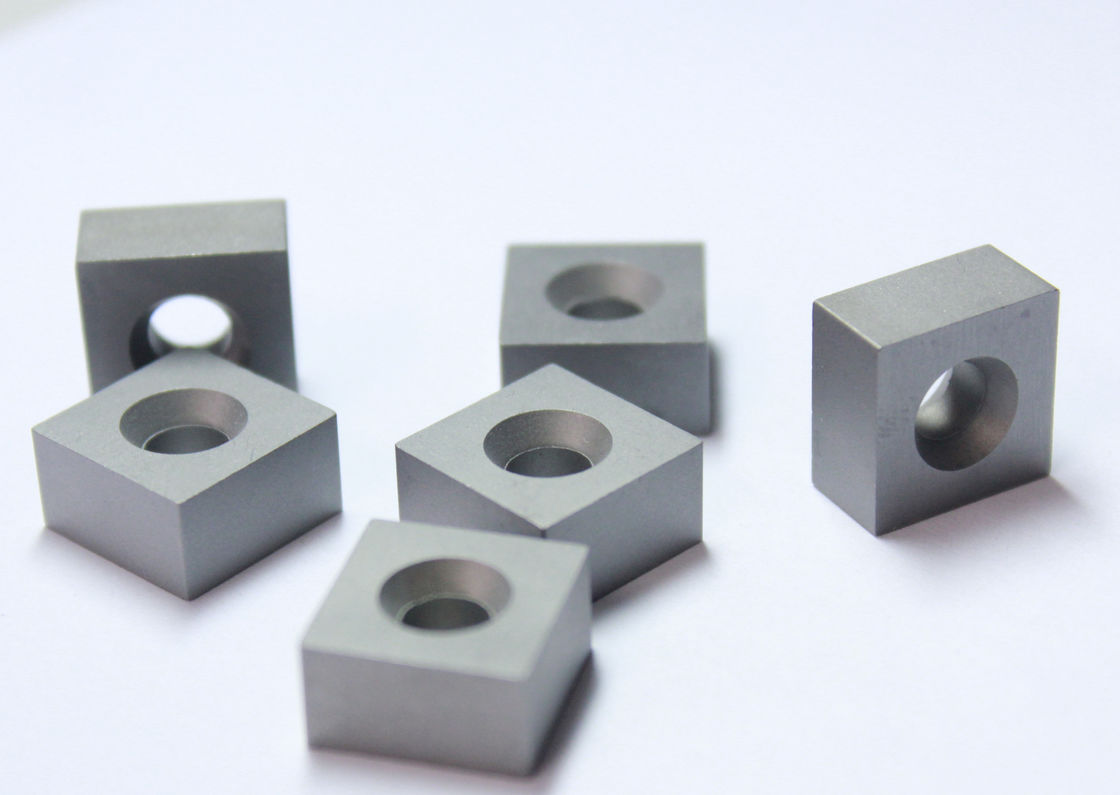

100% Virgin Tungsten Carbide Milling Inserts

Product Details:

| Place of Origin: | ZHUZHOU |

| Brand Name: | NONE |

| Certification: | ISO9001:2008 ISO14001:2004 |

| Model Number: | MANY |

Payment & Shipping Terms:

| Minimum Order Quantity: | 5KG |

|---|---|

| Packaging Details: | 10 pieces / box, plastic box, brown paper box, Blister packing,wooden case |

| Delivery Time: | 15-20 DAYS |

| Supply Ability: | 50000pcs per month |

|

Detail Information |

|||

| Usage: | Cutting Stone | Hardness: | HRA85~89 |

|---|---|---|---|

| Material: | 100% Virgin Tungsten Carbide | ISO Grade: | YG6, YG8,YG8C,YG11C, YG13C.. |

| Type: | Power Tool Parts | ||

| Highlight: | carbide tool inserts,carbide milling inserts,Virgin Tungsten Carbide Milling Inserts |

||

Product Description

Stone cutting 100% virgin Tungsten Carbide Inserts for chainsaw

description:

WE supply top quality chainsaw cemented carbide insert for you,

owning the advanced technology on Tungsten carbide stone cutting ss10 ,

we continuously improve the product to fulfill your requirements. It is aimed

at different countries’ condition, so we’ve developed unique and

Great grades for better application. each has widely been using in Italy, Kenya, Egypt markets.

Chossing right supplier, Saving your cost and time.

PRODUCT FEATURES

1. Grades can be designed according to your requirements and stone diversity. Our engineers

provide helpful suggestions for you.

2. 100% precise raw material makes longer using life.

3. Precise molds produce products with more accurate dimension.

4. Strict products filtering ensure reaching to qualified standard.

5. Enhancement of processing reduced inferior products, increased wear resistance.

6. Full selections of types, grades, sizes available, decreasing your cost and shortening

delivery time.

APPLICATION

inserts for chainsaw is brazed into steel blades, installed on stone quarry machines,

fit for limestone, sandstone,tufa, vulcanic and calcareous stoneblocks cutting.

OEM is also acceptable.

![]()

|

Grade |

Density |

Hardness |

TRS |

|

|

(g/cm3) |

(HRA) |

(Mpa) |

|

YG6 |

14.9 |

91 |

1800 |

|

YG6X |

14.8 |

92 |

1800 |

|

YKM6A |

14.7 |

92.5 |

1800 |

|

YG8 |

14.8 |

90 |

1950 |

|

YT5 |

13 |

90.8 |

1900 |

|

YT14 |

11.5 |

91.5 |

1500 |

|

YT15 |

11.3 |

91.8 |

1450 |

|

YW1 |

13.1 |

91.5 |

1600 |

|

YW2 |

13.1 |

91 |

1600 |

|

YS25 |

12.8 |

91.5 |

1900 |

|

YC30S |

12.8 |

91 |

2000 |

|

ZP35 |

12.8 |

91 |

2000 |

|

YC40 |

13.2 |

90 |

1850 |