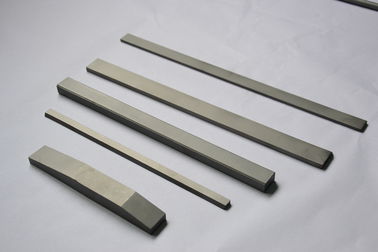

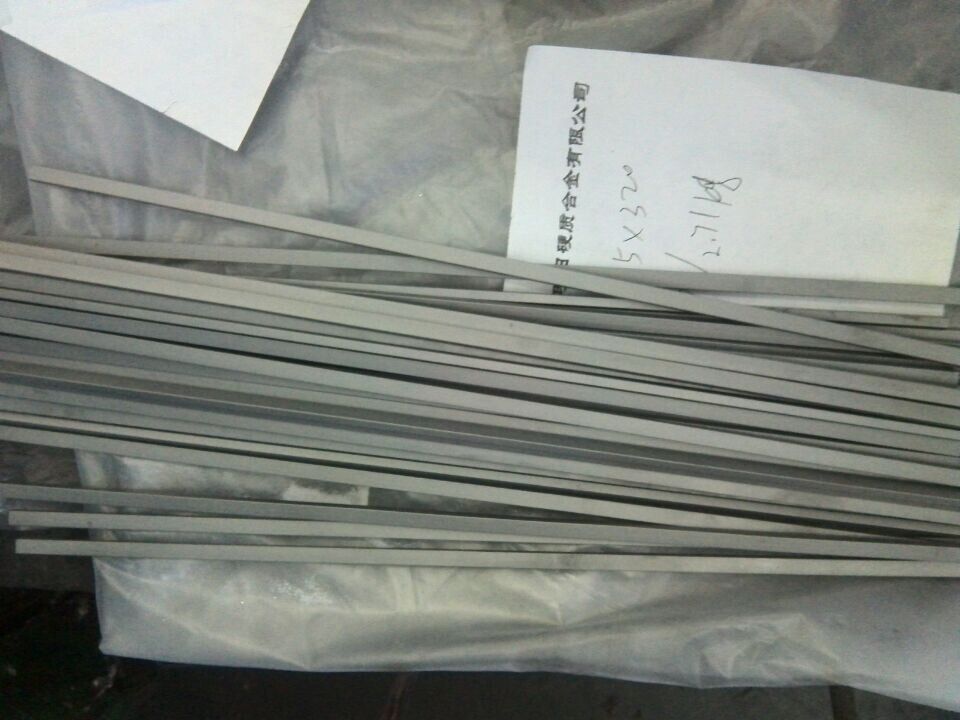

YL10.2 Tungsten Carbide Strips for milling machine processing

Product Details:

| Place of Origin: | ZHUZHOU |

| Brand Name: | none |

| Certification: | ISO9001:2008 ISO14001:2004 |

| Model Number: | many |

Payment & Shipping Terms:

| Minimum Order Quantity: | 10 kg |

|---|---|

| Packaging Details: | plastic box, brown paper box, wooden case |

| Delivery Time: | 2-3 weeks |

| Supply Ability: | 20tons / month |

|

Detail Information |

|||

| Dimensions:: | Tool Part, W*T*310MM, Customized Avaliable | Keywords: | Tungsten Cabride Cemented Carbide Strips |

|---|---|---|---|

| Chemical Composition: | WC, Co | Grade: | YG6 YG8 K10,K20,YL10.2 |

| Application: | Lathe And Milling Machine Processing | Samples: | Available |

| Type: | Power Tool Parts | ||

| Highlight: | tungsten carbide bar,tungsten carbide plate |

||

Product Description

YL10.2 Tungsten Carbide Strips for milling machine processing

a×b×L |

a (mm) |

b (mm) |

L (mm) |

a×b×L |

a (mm) |

b (mm) |

L (mm) |

| 3~8+0.2+0.4 | 1~3+0.15+0.35 | 330+0+3.0 | 14~34+0.4+0.6 | 2~5+0.15+0.35 | 330+0+3.0 | ||

| 8~14+0.3+0.5 | 2~5+0.15+0.35 | 330+0+3.0 |

Cemented carbide strips are usually used for general wood cutters / hard wood cutters ,plastic and tobacco cutting . and meet the ISO9001:2008 quanlity standard. We can make the shipment in the shortest delivery time wtih the compeititve price than any other factory.

We can manufacture various cemented carbide stipes and plate as per customer's requirments based on the differente markets. Our main products include :Cemented carbide drills, cutting cutters, mining tools, drawing dies ,carbide stripes ,rods etc.

Skillful workers and advanced euquipments can make every of your size possible.

Different grade are available too.

We take great efforts to increase commodity types rather than quantitiy to promote the flexibility of competing in the worldmarket. Above all , our client;s demands are always the first to be considered..

Regular Specification:

Width: 3-16, 18, 20, 22, 25, 28, 30, 32, 35, 40, 70 mm

Thickness: 1.5-6 mm

Length: 310 mm( we can cut it to different length as required.)

|

Grades k |

Equal to |

Density |

TRS |

Hardness |

Application |

|

YG7 |

K10 |

14.8 |

1950 |

90.5 |

Better wear resistant than Mk6,used for hard wood used for processing original wood,aluminum section bar,brass rod and cast iron. |

|

YG6 |

K10 |

14.85 |

1900 |

90.8 |

Has wear resistance higher than Mk6,used for processing hard wood, original wood,aluminum section bar,brass rod and cast iron. |

|

YG8 |

K20 |

14.7 |

1950 |

89 |

Wear and percussion resistance,used for processing hard wood, soft wood ferrous and non-ferrous. |

|

YG8A |

K20 |

14.7 |

2000 |

89.5 |

Wear and percussion resistance,used for processing hard wood, soft wood ferrous and non-ferrous. |

|

YG10X |

K40 |

14.5 |

2000 |

91 |

Suitable for processing hard wood,veneer board,PCB,PVC&metals |

|

YG12C |

K40 |

14.3 |

2500 |

87.4 |

For crashing the granite, marble, cobble etc |

Applications:

Carbide strip is widely used for general wood cutters / hard wood cutters, plastic and tobacco cutting.

And it is suitable for the production of various types of motors, electronic progressive dies punches.

Tungsten Carbide - Main Property:

1. Excellent Hardness: 86~93 HRA, which equal to 68~81HRC;

2. Excellent hot working performance: Hardness could be remained at 60 HRC under 900~1000 ℃

3. Excellent wear resistance;

4. High cutting speed;

5. Long service life