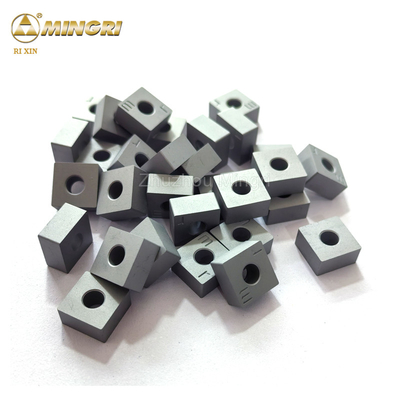

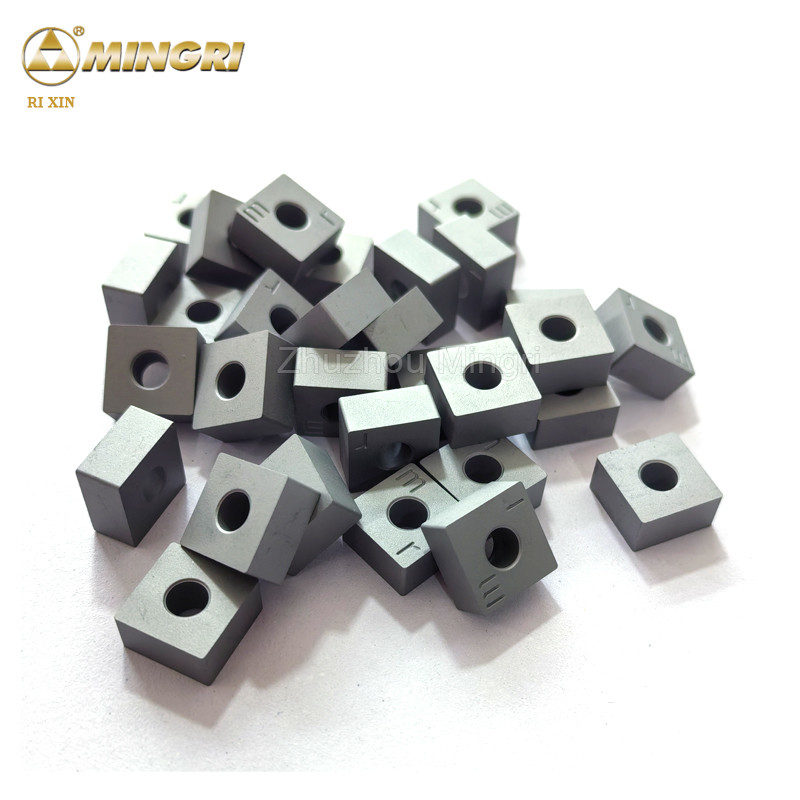

Stone Cutting Chain Saw Insert Tungsten Carbide / Cemented Carbide / Widia Material With High Performance

Product Details:

| Place of Origin: | Zhuzhou Hunan |

| Brand Name: | none |

| Certification: | ISO9001:2004 ISO14001:2004 |

| Model Number: | many |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100 pcs |

|---|---|

| Packaging Details: | 1. export standard wooden cases 2. export standard paper boxes 3. as client's request |

| Delivery Time: | 10-15 days |

| Supply Ability: | 10000 pcs |

|

Detail Information |

|||

| Grade: | YG6, YG8, YK05, MR06H, YG8C, ZD15, YG9C, YG10C, YG11C, YG13C, YG15C, YG15 | Size: | Customized Or Standard |

|---|---|---|---|

| Application: | Crewed On The Chain Saw Of Stone Cutting Machines Such As BENETTI GARRONE KORFMANN | Country Of Origin: | Zhuzhou, China |

| Brand: | Rixin | Usage: | Crewed On The Chain Saw Of Stone Cutting Machines Such As BENETTI GARRONE KORFMANN |

| Material: | Tungsten Carbide, Cemented Carbide, Widia | Sizes: | 12.7x12.7x6.5, 15x10x5, 20x12x3, Other Sizes Can Be Customized |

| Highlight: | Tungsten Carbide Chain Saw Insert,Cemented Carbide Chain Saw Insert,Widia Material Chain Saw Insert |

||

Product Description

Product Description:

Tungsten Carbide Inserts are an essential tool for various industrial applications, known for their durability and precision cutting capabilities. These inserts are available in both customized and standard sizes, catering to a wide range of cutting needs.

Hailing from the renowned manufacturing hub of Zhuzhou, China, these Tungsten Carbide Inserts boast exceptional quality and performance. The country of origin ensures that the inserts are produced using advanced technology and stringent quality control measures, meeting international standards.

When it comes to the surface finish, these inserts offer versatility with options such as ground, sintered blasting, nickel coating, and tumble finishing. Each surface finish serves a specific purpose, whether it's enhancing wear resistance, reducing friction, or improving cutting efficiency.

The Tungsten Carbide Inserts are commonly used as carbide cutting teeth in various cutting tools, making them ideal for stone cutting applications. Their precision and hardness make them a reliable choice for demanding tasks that require consistent cutting performance.

Whether you're in the stone cutting industry or need reliable chain saw parts, these Tungsten Carbide Inserts are designed to meet your requirements. The inserts provide long-lasting performance, ensuring that your tools operate efficiently and effectively.

In addition to stone cutting, these inserts are versatile enough to be used in various applications where carbide cutting teeth are required. From woodworking to metalworking, the Tungsten Carbide Inserts offer a high level of durability and cutting precision.

Each insert is crafted with precision and expertise, incorporating the latest advancements in carbide insert technology. The result is a product that delivers consistent performance and longevity, even in the most demanding cutting environments.

Key Features:

- Customized or standard sizes available

- Country of Origin: Zhuzhou, China

- Surface options: Ground, Sintered Blasting, Nickel Coating, Tumble Finishing

- Keywords: Tungsten Carbide Insert, Stone Cutting Insert, Chain Saw Part, Tungsten Carbide Tip

- Product Category: Tungsten Carbide Inserts

Features:

- Product Name: Tungsten Carbide Inserts

- Advantages:

- High quality & virgin raw material with stable properties and long working life

- Dark grey surface with hot sale at Kenya, Egypt, Libya, Italy and Greece market

- Precision dimensions with good unit weight and size accuracy

- Various sizes and types for your choice

- Longstanding old customers with over tons export amount every month

- Sample: Acceptable

- Usage: crewed on the chain saw of stone cutting machines such as BENETTI GARRONE KORFMANN

- Hardness: HRA 85-90.5

- Surface: Ground, Sintered Blasting, Nickel Coating, Tumble Finishing

Technical Parameters:

| Country of Origin | Zhuzhou, China |

| Product Category | Tungsten Carbide Inserts |

| Surface | Ground, Sintered Blasting, Nickel Coating, Tumble Finishing |

| Application | Crewed On The Chain Saw Of Stone Cutting Machines Such As BENETTI GARRONE KORFMANN |

| Size | Customized Or Standard |

| Keywords | Tungsten Carbide Insert, Stone Cutting Insert, Chain Saw Part, Tungsten Carbide Tip |

| Product Name | 12.7x12.7x6.5 Square Widia Tips High Quality Stone Cutting Tool Tips of Cemented Tungsten Carbide |

| Material | Tungsten Carbide, Cemented Carbide, Widia |

| Sample | Acceptable |

| Grade | YG6, YG8, YK05, MR06H, YG8C, ZD15, YG9C, YG10C, YG11C, YG13C, YG15C, YG15 |

Applications:

Tungsten Carbide Inserts are versatile cutting tools that find application in various industries and scenarios due to their durability and high performance. The 12.7x12.7x6.5 Square Widia Tips are particularly popular for stone cutting machines like BENETTI, GARRONE, and KORFMANN chain saws.

With a hardness ranging from HRA 85 to 90.5, these carbide cutting teeth are designed to withstand the tough conditions encountered during stone cutting operations. The customized or standard sizes available make them suitable for different machine models and cutting requirements.

Manufactured in Zhuzhou, Hunan, these Tungsten Carbide Inserts meet the ISO9001:2004 and ISO14001:2004 certifications, ensuring high quality and environmental standards. Customers can place orders starting from 100 pieces, with a supply ability of up to 10,000 pieces within a delivery time of 10-15 days.

The packaging details include options for export standard wooden cases, paper boxes, or customization based on the client's preferences. This flexibility in packaging ensures safe transportation and delivery of the inserts to the desired location.

Whether it's for industrial stone cutting operations or specific applications in chain saw machines, these high-quality carbide inserts provide efficient cutting performance and long-lasting durability. The keywords Tungsten Carbide Insert, Stone Cutting Insert, Chain Saw Part, and Tungsten Carbide Tip reflect the diverse uses and benefits of these inserts in the cutting tool industry.

Support and Services:

Our Product Technical Support and Services for Tungsten Carbide Inserts include:

- Expert advice on selecting the right inserts for your specific applications

- Guidance on proper installation and maintenance of the inserts

- Troubleshooting assistance to address any issues or concerns

- Access to resources such as product manuals, technical specifications, and application guides

- Training programs to help you optimize the performance of the inserts

Packing and Shipping:

Product Packaging and Shipping for Tungsten Carbide Inserts:

Each tungsten carbide insert is carefully packaged in a protective case to prevent any damages during shipping. The case is then placed in a sturdy cardboard box with padding to ensure safe transportation.

Shipping Method: We use reliable courier services to deliver your tungsten carbide inserts in a timely manner. Tracking information will be provided so you can monitor the status of your shipment.

FAQ:

Q: What is the certification of the Tungsten Carbide Inserts?

A: The Tungsten Carbide Inserts are certified with ISO9001:2004 and ISO14001:2004.

Q: What is the place of origin for the Tungsten Carbide Inserts?

A: The Tungsten Carbide Inserts are from Zhuzhou Hunan.

Q: What is the minimum order quantity for the Tungsten Carbide Inserts?

A: The minimum order quantity for the Tungsten Carbide Inserts is 100 pcs.

Q: What is the supply ability for the Tungsten Carbide Inserts?

A: The supply ability for the Tungsten Carbide Inserts is 10000 pcs.

Q: What are the packaging details for the Tungsten Carbide Inserts?

A: The Tungsten Carbide Inserts are packaged in export standard wooden cases, export standard paper boxes, or as per the client's request.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()