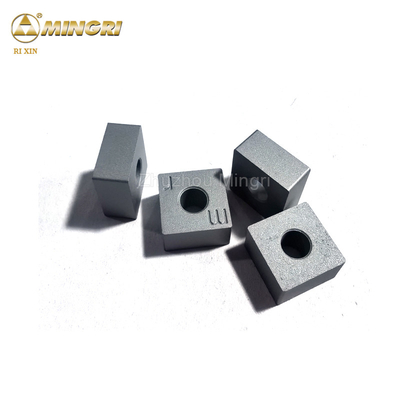

High-Performance Tungsten Carbide Insert HRA 85-90.5 for Chain Saws Customizable OEM Support

Product Details:

| Place of Origin: | Zhuzhou, Hunan, China |

| Brand Name: | RiXin |

| Certification: | ISO9001:2008; ISO14001:2004 |

| Model Number: | Tungsten carbide insert |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 KG |

|---|---|

| Price: | USD+49~69+KG |

| Packaging Details: | paper, then paper boxes, then exported wooden cartons or paper cases,or packed as customers'requirement. |

| Delivery Time: | 7 to 10 working days depending on the order quantity and requirements |

| Payment Terms: | D/A, L/C, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 50 tons/month |

|

Detail Information |

|||

| Product Name: | High-Performance Tungsten Carbide Insert For BENETTI GARRONE KORFMANN Chain Saws Customizable OEM Support | Material: | Tungsten Carbide, Cemented Carbide, Widia |

|---|---|---|---|

| Grade: | YG6, YG8, YK05, MR06H, YG8C, ZD15, YG9C, YG10C, YG11C, YG13C, YG15C, YG15 | Surface: | Ground, Sintered Blasting, Nickel Coating, Tumble Finishing |

| Hardness: | HRA 85-90.5 | Keywords: | Carbide Inserts, Insert Carbide, Tungsten Carbide Stone Cutting Insert, Tungsten Carbide Tip, Chain Saw Parts, Widia Insert For Chain Saw Machines, Tungsten Carbide Chain Saw Parts, 12.7x12.7x6.5 Carbide Insert, Carbide Cutting Teeth, BENETTI GARRONE KORFM |

| Size: | Customized Or Standard | Sample: | Acceptable |

| Application: | Crewed On The Chain Saw Of Stone Cutting Machines Such As BENETTI GARRONE KORFMANN | ||

| Highlight: | OEM Tungsten Carbide Insert,High Performance Tungsten Carbide Insert,Customizable Tungsten Carbide Insert |

||

Product Description

High-Performance Tungsten Carbide Insert for BENETTI GARRONE KORFMANN Chain Saws Customizable OEM Support

Description

Key Features:

-

Enhanced Durability for Stone Processing

- Engineered with cryogenically treated tungsten carbide substrate, these inserts exhibit superior wear resistance and microstructural stability, proven to extend tool life by over 30% in high-impact stone cutting operations12.

- Optimized edge geometry minimizes chipping during granite or marble cutting, ensuring consistent precision even under prolonged use1.

-

High-Efficiency Cutting Performance

- Advanced tooth profiles and coatings reduce cutting resistance by up to 25%, enabling faster feed rates and smoother material removal in stone milling applications13.

- Compatible with multi-brand machinery, including BENETTI GARRONE KORFMANN systems, for seamless integration into existing workflows1.

-

Customizable Solutions for Complex Tasks

- Tailored OEM support allows parameter adjustments (e.g., edge angles, coating thickness) to match specific stone types (e.g., quartzite, basalt), balancing speed and surface finish quality13.

- Modular designs support rapid tool replacement, reducing downtime in high-volume production environments3.

Application Scenario

In industrial stone quarries, these inserts demonstrate exceptional performance during 10-hour shifts of continuous granite slab cutting. The cryogenically treated structure maintains edge sharpness under thermal stress, while customized coatings prevent abrasive wear from silica-rich materials, achieving 20% higher daily output compared to standard tools

| Item | Tungsten carbide stone cutting insert |

| Grade | YG6, YG8, YK05, MR06H, YG8C, ZD15, YG9C, YG10C, YG11C, YG13C, YG15C, YG15. |

| Sizes | 12.7x12.7x6.5,13x13x7 other sizes can be customized |

| Brand | Rixin |

| Country of Origin | Zhuzhou, China |

| Usage | crewed on the chain saw of stone cutting machines such as BENETTI GARRONE KORFMANN |

Carbide Inserts, insert carbide, tungsten carbide stone cutting insert, tungsten carbide tip, chain saw parts, Widia insert for chain saw machines, tungsten carbide chain saw parts, 12.7x12.7x6.5 carbide insert, carbide cutting teeth, BENETTI GARRONE KORFMANN machine, OEM tungsten carbide insert for BENETTI, carbide stone cutting tip, carbide tool parts inserts, 12.7x12.7x6.5 Square Widia Tips, power tool cutting inserts carbide

Grades:

| Grades |

Density g/cm³ |

T.R.S Mp α |

Hardness HRA |

Performance &application recommended | Approx grades in China | ISO Grade |

| MK4 | 15.1 | 1800 | 90.0 | Mainly used as small buttons for percussion bits to cut soft and medium hard formations. | YG4C | K01-K05 |

| MK6 | 14.9 | 2100 | 90.5 | For coring crowns, electric coal drill bits, coal cutting picks, oil cone bits and scraping knife bits, used in geological prospecting, coal mining and oil well boring. | YG6 | K10 |

| MR06H | 14.94 | 3000 | 90.5 | Good strength and wear resistance, for bits of rotary hammer rock drills and heavy rock drills, for hard and very hard rocks. | YK05,KK06H | K10 |

| MK8 | 14.7 | 2800 | 89.8 | For coring crowns, electric coal drill bits, coal cutting picks, oil cone bits and scraping knife bits, used in geological prospecting, coal mining and oil well boring. | YG8 | K20 |

| MK10 | 14.7 | 2700 | 89 | Mostly used as the buttons of small and medium sized percussion bits and as the inserts of rotary prospecting bits to cut soft and medium hard formations. |

YG8C ZD15 |

K20 |

| MK15 | 14.6 | 2750 | 88 | Suitable for strips, conical buttons for rotary percussion drill bits, geological prospecting buttons, cut soft and medium hard formations. |

YK15 YG9C |

K20-K30 |

| MK20 | 14.5 | 2800 | 87.5 | Primarily for the buttons and inserts of rotary percussion bits to cut medium-hard and hard formations. |

YK20 YG10C |

K30 |

| MK30 | 14.4 | 2850 | 87.0 | Largely used for the inserts and buttons of percussion bits and tricone bits to cut medium-hard, hard and very hard formations. | YG11C | K20-K30 |

| MK40 | 14.2 | 2900 | 86 | Mainly used for the buttons of tricone bits, and inserts of rotary percussion bits to cut hard and very hard formations. |

YK40 YG13C |

K40 |

| MK50 | 14.0 | 3000 | 85 | For oil cone drill bits, for medium soft and medium-hard rocks. | YG15C | K40 |

| MK60 | 14.0 | 3000 | 87 | Good strength and less wear resistance, for bits of rotary hammer rock drills and heavy rock drills, for hard and very hard rocks. | YG15 | K40 |

Other grades can be supplied according to customers’ requirements.

Types:

![]()

Other types can be supplied according to customers’ requirements.

Application:

![]()

![]()

Package:

| Packing | Paper+paper boxes+exported wooden cartons or paper cases. As a manufacturer, Mingri can provide any kinds of package as buyer's requirement. |

| Shipping | UPS,TNT,EMS,Fedex,DHL,or as you request. |

| Delivery | 7-10 days after confirm all details. |

![]()

Main products:

We are specialized in all kinds of tungsten carbide profiles and dies, cutting tools, mining tools, wear parts and all kinds of non-standard customized tool parts with high performance in the industry.

For details about the below products, please click the More on below pictures:

For details about our company, equipments, inspection and quality, please refer to

http://www.tungstencarbide-tools.com/aboutus.html

http://www.tungstencarbide-tools.com/factory.html

http://www.tungstencarbide-tools.com/quality.html