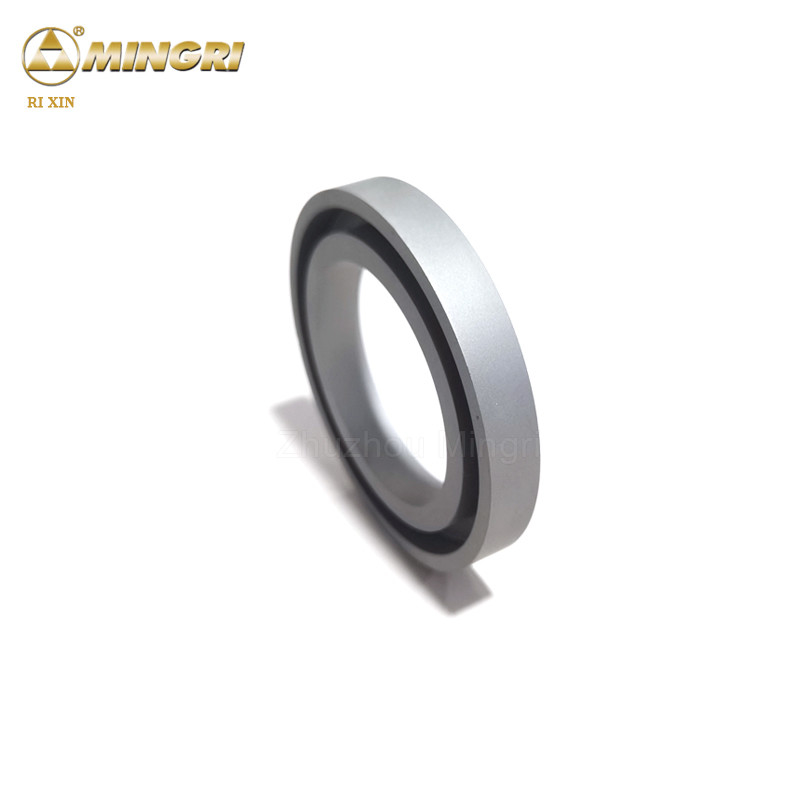

Tungsten Carbide Circular Solar Battery Lithium Ion Battery Cutting Blade

Product Details:

| Place of Origin: | China |

| Brand Name: | Rixin |

| Certification: | CE ROHS UL ISO |

| Model Number: | 98mm*66mm*0.7mm |

Payment & Shipping Terms:

| Minimum Order Quantity: | 5 piece |

|---|---|

| Packaging Details: | Cartons |

| Delivery Time: | 15-20 days |

| Payment Terms: | T/T |

| Supply Ability: | 50+tons+per month |

|

Detail Information |

|||

| Keyword: | Carbide Cutting Blade | Material: | 100% Raw Material |

|---|---|---|---|

| Usage: | Battery Cutting | Application: | Cutting Machine |

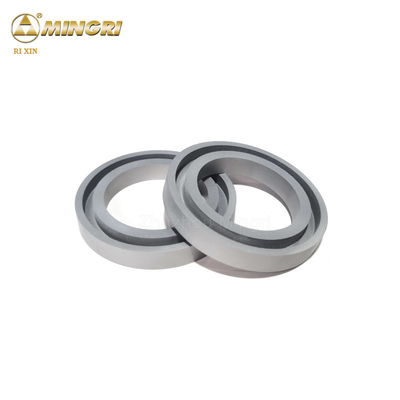

| Product Name: | Carbide Cutting Blade | Surface: | Blanks And Sand Blasting |

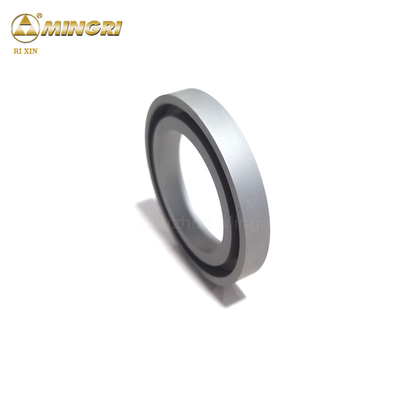

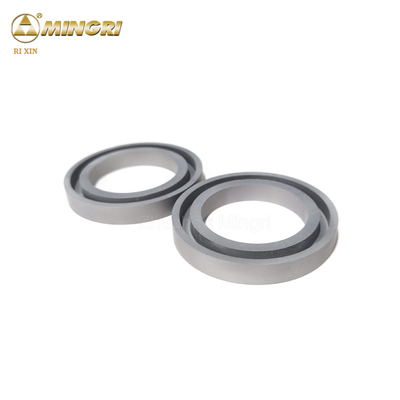

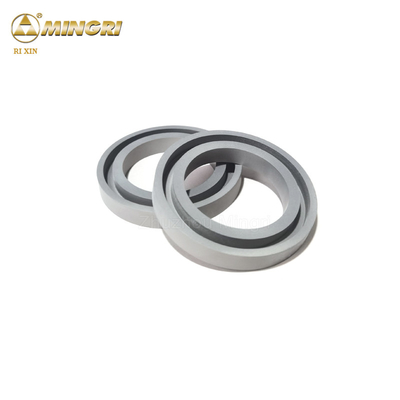

| Shape: | Round With Groove | Colour: | Sliver |

| MOQ: | 5PCS | Origin: | Zhuzhou City From China |

| Highlight: | Circular Battery Cutting Blade,Tungsten Carbide Battery Cutting Blade,Lithium Ion Battery Cutting Blade |

||

Product Description

Tungsten Carbide Circular Solar Battery Lithium Ion Battery Cutting Blade

Advantage of carbide cutting blade

1, This kind of knive is made by best pure tungsten carbide raw material, guaranteed high hardness and high wear resistance.

2, The cutting edge is very sharp, flatness and high precision degree.

3, Widely used for slitting corrugated board is domestic and oversea machines or production lines.

Production description of carbide circular slitting blade

| Grade | Density | T.R.S | Hardness | characteristics and Application |

| g/cm3 | ≥ N/mm2 | HRA | ||

| MR020 | 14.35-14.5 | 3000 | 91.8 | Sub-micron grain,apply to cutting corrugated board,chemical fiber,plastics,leather,battery pole pieces,all kinds of milling cutters and hole-machining tools |

| MR030 | 13.95-14.1 | 3200 | 90.5 | Sub-micron grain,superb abrasive resistance and toughness,apply to woodworking cutters,cutting corrugated board,battery pole pieces etc |

| MR040 | 13.8-13.95 | 3200 | 89.8 | Sub-micron grain,superb abrasive resistance and toughness , apply to woodworking cutters, rolling shear blades, suitable for cutting paperboard |

| 3 | φ68/72/76*φ46*0.5/1 | TOP KNIFE |

| 4 | φ60*φ40*5 | BOTTOM |

| 5 | φ100*φ65*0.7 | |

| 6 | φ100*φ65*2 | |

| 7 | φ100*φ65*1 | |

| Acceptable for customer's design | ||

Appllication of carbide cutting blade

Widely use for battery industry cutting, and all kinds of non ferrous for cutting.

Production and test of carbide cutting blade

First step ----- Soon after the order is confirmed, carbide circular slitting blade products will start to prepare the RTP powder

Second step ---- Before mass production, we need to do a trial pressing and sintering using every mould, and we check the appearances and the sizes of carbide circular slitting blade samples .

Third step ----- Bulk production ,press the raw materials to shape blanks

Fourth step ------ Then sinter blanks to finish (HIP) and finished carbide circular slitting blade products inspection ensure the best quality and production capacity.

Packing and delivery of carbide cutting blade

PACKING DETAILS : Rubber protector for cutting edges, blade in bubble pack, carton case.

Max 10 pcs blades in one carton case

Delivery Details : We cooperate with many well-known express company, such as UPS, FedEx, DHL, TNT etc.

We promise 1 week quick delivery to our customers.

company information

230 workers, 8000 m2 non-dust workshop, 18 years experience , 10000 sets mould, 5 workshop included grinding powder workshop, pressing workshop, sintering workshop, processing workshop, mould production workshop, production capacity 50tons/month, well-known brand ”Ri Xin” has registered in Europe for 6 years , ISO, CE&FDA certificated, one hour reach Shanghai port, this is how we keep superior quality and competitive offers for global valued customers.

Our main products cover cold heading dies, wire drawing dies, strips and plates, saw tips, brazed tips, disc cutters, round rods, rock drilling bits and buttons, milling tools, also we can make all kinds of customized proposal to meet customers’ requirement.

![]()