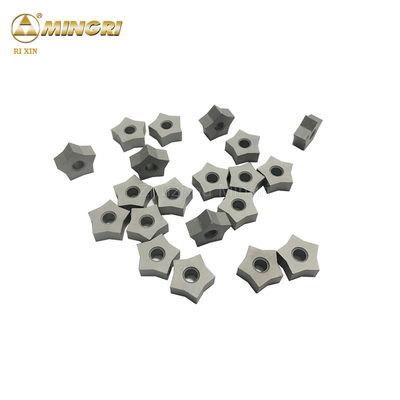

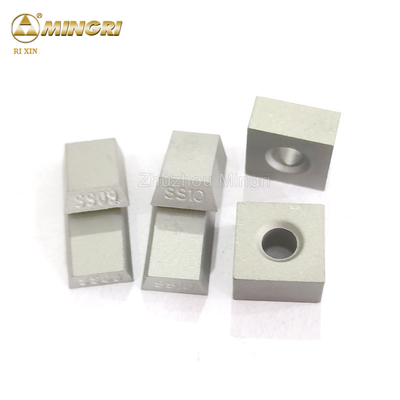

Stone Cutting Tungsten Carbide Insert for BENETTI, GARRONE, KORFMANN Chain Saw Machine

Product Details:

| Place of Origin: | China |

| Brand Name: | Rixin |

| Certification: | CE ROHS UL ISO |

| Model Number: | YG6 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 5KG |

|---|---|

| Packaging Details: | Cartons |

| Delivery Time: | 7-15 days |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 50+tons+per month |

|

Detail Information |

|||

| Product Name: | Tungsten Carbide Insert | Material: | Tungsten Carbide |

|---|---|---|---|

| Keyword: | Tungsten Carbide Insert | Usage: | Cutting Marble Stone |

| ODM/OEM: | Yes | Size: | 12mm * 12mm * 6mm |

| Surface: | Sand Blasting | Grade: | YG8, YG6 |

| Delivery Time: | 15 Days | Packing: | Carton |

| Highlight: | KORFMANN Tungsten Carbide Insert,odm Tungsten Carbide Insert,Chain Saw Machine Carbide Insert |

||

Product Description

Stone Cutting Insert Tungsten Carbide Insert for BENETTI, GARRONE, KORFMANN Chain Saw Machine

Description for carbide tips

Main types: 12.7x12.7x4.5-7.0;13.1x13.1x4.5-7.0;13.3x13.3x4.5-7.0

Optional Grade : YG6/YG7/YG8/YG10/YG8C/YG10C ;

| Grade | Density g/cm3 | Hardness HRA | T.R.S MPa | Performance&application recommend |

| YM6A | 14.85 | 92.5 | 2200 | suitable for the smei-finishing cast iron and nonferrous metals and also for the machining of manganese steel and hardened steel |

| YM6X | 14.9 | 91.5 | 2300 | suitable for the smei-finishing cast iron and nonferrous metals and also for the machining of manganese steel and hardened steel |

| YM6 | 14.95 | 90.5 | 2400 | suitable for finishing and semi-finishing of stainless and conventional alloy steel |

| YM8 | 14.7 | 89.8 | 2800 | suitable for finishing and semi-finishing of stainless and conventional alloy steel |

| YT15 | 11.4 | 91.5 | 1600 | suitable for the finishing and semi-finishing for steel and cast steel with a moderate feed rate and rather high cutting speed |

| YT5 | 12.9 | 90.5 | 2200 | suitable for the heavy cutting of steel and cast steel with a big feed rate at a medium and low speed under unfavorable working conditions |

![]()

![]()

Our advantage of carbide tips

1. Best and stable quality at most competitive price.

We only use the finest virgin tungsten carbide powder, in this way we can offer you optimum characteristics for your application. Continuous quality control at all intermediate stages of the manufacturing process ensures consistent high quality.

2. Rapid production and delivery time.

Factory-direct shipment ensure short delivery time when you need it, 15~25 days.

3. We treat our customers like we would like to be treated.

Experienced team on your service to help you find a solution that will offer increased productivity and longer life, reducing down time and saving you money.

Production application of carbide tips

Tungsten carbide insert we developed is suited to FANTINI, DAZZINI, BENETTI, GARRONE etc stone quarries chain saw cutting machine.

Tungsten carbide insert is used for cutting marble stone

Packing and Shipping of carbide tips

1, we will take care of your machine packages well .

2, our worker will make sure your carbide tips clean before package.

3, add plastci foam into inner box for the whole carbide tips for sweet protection.

4, we will make export standard strong cartonn or plywood case package according to your needs.