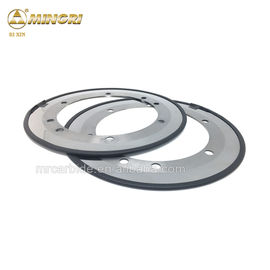

High Hardness Carbide Disc Cutter Round Blade For Slitting Corrugated Board Paper

Product Details:

| Place of Origin: | ZHUZHOU,HUNAN,CHINA |

| Brand Name: | RI XIN |

| Certification: | ISO9001:2008 ISO14001:2004 |

| Model Number: | MR020 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 5pcs |

|---|---|

| Price: | As per specific requirements |

| Packaging Details: | First in small cartons filled with cotton, then in bigger cartons. |

| Delivery Time: | 7-20 days |

| Payment Terms: | L/C, D/A, D/P, T/T |

| Supply Ability: | 50 Tons per month |

|

Detail Information |

|||

| Features: | High Hardness,Good Impact Resistance,High Wear Resistance | Material: | WC+Cobalt |

|---|---|---|---|

| Grade: | MR020/MR030 | Application: | For Cutting Corrugated Paper |

| Surface Treatment: | Polishing | Size: | Customer Requst |

| Hardness: | 90-93 HRA | TRS: | 2400-3600 |

| Character: | With Holes Or Without | Process: | 5 Steps Or More Than |

| Highlight: | tungsten carbide blade,carbide rotary cutter |

||

Product Description

Cemented carbide round blade for slitting corrugated board paper 260*168.3*1.2 mm 8 holes

Applications:

Tungsten carbide disc cutter is suitable for cutting the slitting corrugated board/paper

| items | Common size (mm) | Holes | Machine |

| 1 | φ260φ168.3*1.2 | 8 | Marquip |

Character:

The blade is made by best pure tungsten carbide raw material,then can guarantee high hardness and high wear resistance,the cutting edge is very sharp,flatness and high precision degree.

Details :

![]()

tungsten carbide steel blade is mainly used for cutting paper

tungsten carbide steel knife products require high precision, no glitches, maximum abrasion resistance.

we are using HIP sintered and fine grinding, polishing plating to reduce frictions when cutting, improved the accuracy and speed slitting greatly, tool life extended!

![]()

1.Mix with Cobalt powder

2. Ball mix:All the round rods in the ball mills should be made of fine grain tungsten carbide rods,glue mixing is usually mix the rubber, make the blade sometimes mix

3.The choice of pressing machinery depends on the surface area of the product to be pressed

surface area multiplied by 0.8 is pressure value . 1000 tons means that the maximum pressure ,of 1000 tons products can be pressed, and each machine can adjust the appropriate pressure.

4.First,we will do degumming then we’ll use HIP sintering or vacuum sintering.we have 10 vacuum sintering furnace and 2 HIP furnace

We will use testing tablet when sintering to test the raw material performance .

For carbide antiskid stud,they are putting inside vaccum sintering furnace by degarmming and sintering together

For small products,normally under 200 gram,we will use degumming and sintering together in HIP sintering furnace

If for big products,for example carbide dies,plates ,Grade ML serious,we should do degumming firstly then use HIP sintering furnace

5.Our order,normally is blanks or ground

For customer’s grinding tolerance, we will grind/machine outside diameter ,inside diameter /the sharp edge and so on

So we will use surface grinding machine,centerless grinding machine ,cylindrical grinding machine

![]()

Testing and quality control

1.Conduct product inspection in strict accordance with the inspection procedures, be responsible for the quality of the products being inspected.

2.The inspection is supplemented by inspections, mainly for prevention, and the inspectors are responsible for the occurrence of batch scrap.

3.Occurrence of defective products, scrap, timely isolation and reporting

4.Products have been inspected should be clearly marked and untested to avoid confusion.

5.Do product inspection and unqualified product identification.

6.Some problems in semi-finished products: the actual size and the single weight do not match the size and single weight on the press process card, delamination, cracks, surface stickiness , and not pressing well.

![]()

About package :

Please check the photo,we will do our best to protect your goods be well packed

![]()

Feel free to contact me if any needs:

Whatsapp/wechat/phone:008618593402651

Facebook:Xiao Aimee

zhuzhou mingri cemented carbide co. ltd

Email:mr009@mrcarbide.com

![]()