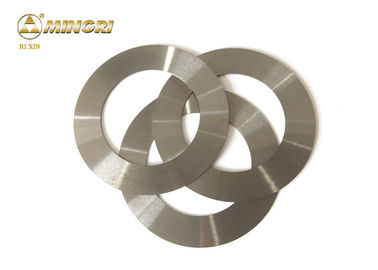

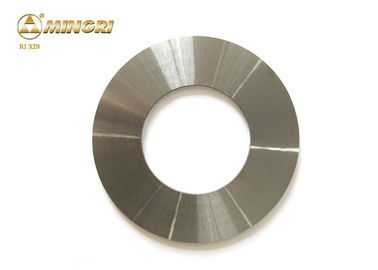

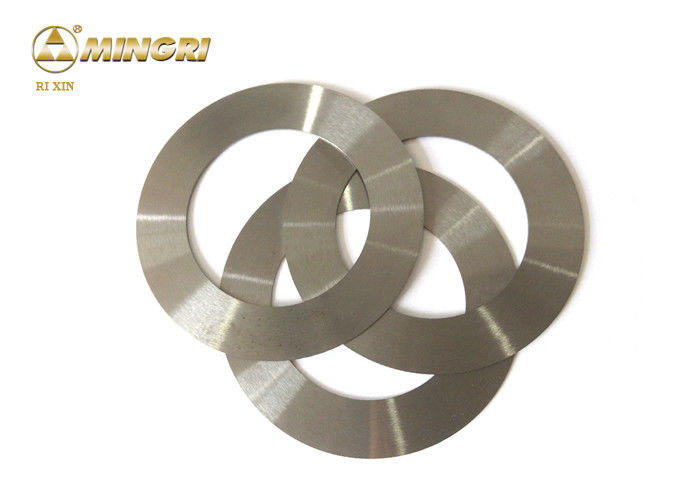

High Precision Carbide Disc Cutter Wear Resistance Hard Alloy Knives For Battery Cutting

Product Details:

| Place of Origin: | ZHUZHOU,HUNAN,CHINA |

| Brand Name: | RI XIN |

| Certification: | ISO9001:2008 ISO14001:2004 |

| Model Number: | K10,K20,K30,K05,K40 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1KG |

|---|---|

| Price: | 32.68$/kg-68.59$/kg |

| Packaging Details: | 1. Rubber protector for cutting edges, blade in bubble pack, carton case. Max 10 pcs blades in one carton case 2. Exterior packaging: carton or wooden case |

| Delivery Time: | 15-25 business days |

| Payment Terms: | L/C, D/A, D/P, T/T, L/C, T/T, Western Union |

| Supply Ability: | 50 Tons per month |

|

Detail Information |

|||

| Features: | High Hardness,Good Impact Resistance,High Wear Resistance | Material: | Tungsten Carbide+cobalt |

|---|---|---|---|

| Grade: | MR020 MR030 | Application: | Machine Battery |

| Surface Treatment: | Polishing,sand-blasting | Hardness: | 89-91 HRA |

| TRS: | 2800-3200 | Density: | 14.1-14.5 |

| Highlight: | tungsten carbide blade,carbide rotary cutter |

||

Product Description

Tungsten Carbide Blade For Battery cutting with high precision and wear resistance hard alloy knives

Zhuzhou MingRi Cemented carbide co.,ltd is located in the tungsten carbide hometown , convenient transportation, from changsha airport just 40 minutes, wuhan just 1.5 hour, from guangzhou just 2 hours. A favorable peripheral environment for cemented carbide manufacturing provides a natural barrier. Convenient traffic for tomorrow's internationalization laid a wide road.

Applications:

Tungsten carbide disc cutter is suitable for semifinishing the chilled cast iron, nonferrous

metal and its alloy. It is also suitable for semifinishing and finishing the hardened steel

and alloy steel.

![]()

Grade and Applications:

| Grade | ISO | Hardness | Density | TRS MPa |

| MR020 | K20-K30 | 91.8 | 14.35 | 3000 |

| MR030 | K40 | 90.5 | 14.1 | 3200 |

Common size:OD*ID*T(mm)

φ68/72/76*φ46*0.5/1

φ60*φ40*5

φ98*φ66*0.7

φ80*φ55*5

φ100*φ65*0.7

φ100*φ65*1

φ110*φ90*1

φ110*φ75*3

φ110*φ90*3

φ130*φ88*1

Characteristic :The blade has good appearance,high consistency and wear resisitance,the cutting edge can pass the inspection of enlarging 200 times without chips on it.Guranteed cutting quality,long working life,also the frequency of replacing blades is very low with high cost performance

![]()

Character

The blade has good apperance,high consistency and wear resistance,the cutting edge can pass the inspection of enlarging 200 times without chips on it,guaranteed cutting quality,long working life,also the frequency of replacing blades are very low with high cost performance

![]()

![]()

Package:

1. Rubber protector for cutting edges, blade in bubble pack, carton case.

Max 10 pcs blades in one carton case

2. Exterior packaging: carton or wooden case

3. Other packaging upon your request

4. We also have the professional agents shipping our products to the customers.

![]()