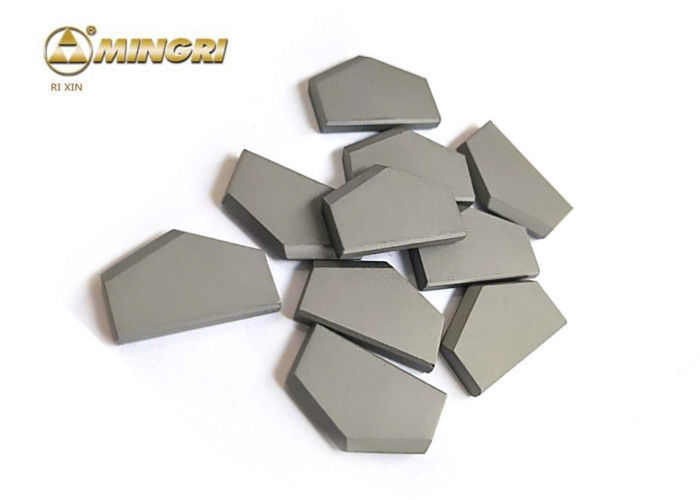

Hammer Drill Tungsten Carbide Cutting Tips , Cemented Carbide Tips Sliver Gray Color

Product Details:

| Place of Origin: | China |

| Brand Name: | Rixin |

| Certification: | ISO9001:2008 |

| Model Number: | customized |

Payment & Shipping Terms:

| Minimum Order Quantity: | 10kg |

|---|---|

| Price: | USD + 32~62 + KG |

| Packaging Details: | cartons |

| Delivery Time: | 5-15 days |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 50+tons+per month |

|

Detail Information |

|||

| Features: | Super Quality / Long Using Life | Product Name: | Carbide Cutting Tips |

|---|---|---|---|

| Keyword: | Carbide Cutting Tips | Material: | Tungsten Carbide |

| Grade: | YG10X | Application: | Drill Steel Reinforced Concrete Wall |

| Highlight: | tungsten carbide cutting tips,cemented carbide tips |

||

Product Description

brazed on Electric Rotary Hammer SDS Drill tungsten carbide Bits Cutting Tips

advantage of carbide cutting tips

Product Name: carbide cutting tips

Material: tungsten carbide

Color: sliver gray

Standard: ISO

Material: YG8,YG6,YG10,YG10X

Application: widely used for drilling building, geology and coal mining and heavy rock

|

Grade |

|

|

|

Applications recommended | ISO Code |

|

|

|

|

|||

|

|

|

|

|

Used for deep well or heavy rock drill |

K30

|

| MR8-B | 14.7 | 88.5 | 2700 | Suitable for hard rock or rock with hard stratum or metallic rock | K20 |

|

Other grades can be offered by customers' requirement

|

|||||

Description of TC carbide cross tips

![]()

![]()

| Specification | D(mm) | W(mm) | T(mm) |

| 4 | 4.37 | 3.40 | 1.00 |

| 4.17 | 3.20 | 0.93 | |

| 5 | 5.37 | 4.20 | 1.20 |

| 5.17 | 4.00 | 1.13 | |

| 6 | 6.37 | 5.00 | 1.40 |

| 6.17 | 4.80 | 1.30 | |

| 6.5 | 6.78 | 5.84 | 1.52 |

| 6.63 | 5.58 | 1.45 | |

| 7 | 7.42 | 5.80 | 1.60 |

| 7.22 | 5.60 | 1.50 | |

| 8 | 8.42 | 5.90 | 1.80 |

| 8.22 | 5.60 | 1.70 | |

| 8.5 | 8.47 | 6.85 | 1.52 |

| 8.32 | 6.60 | 1.45 | |

| 10 | 10.42 | 7.30 | 2.20 |

| 10.22 | 7.00 | 2.05 | |

| 10.11 | 10.08 | 8.37 | 1.98 |

| 9.93 | 8.12 | 1.91 | |

| 12 | 12.47 | 8.70 | 2.50 |

| 12.22 | 8.40 | 2.35 | |

| 13 | 13.43 | 11.30 | 2.31 |

| 13.23 | 10.92 | 2.21 | |

| 14 | 14.47 | 10.10 | 2.80 |

| 14.22 | 9.80 | 2.62 | |

| 15.04 | 15.01 | 12.36 | 2.31 |

| 14.80 | 11.98 | 2.21 | |

| 16 | 16.47 | 10.10 | 2.20 |

| 16.22 | 9.60 | 2.02 | |

| 16.76 | 16.73 | 13.33 | 2.31 |

| 16.53 | 12.95 | 2.21 | |

| 19 | 19.40 | 12.00 | 2.50 |

| 19.25 | 11.50 | 2.32 | |

| 22 | 22.49 | 13.00 | 2.50 |

| 22.26 | 12.50 | 2.30 | |

| 25 | 25.49 | 15.50 | 3.00 |

| 25.26 | 15.00 | 2.80 | |

| All kinds of non-standard drill bits and eccentric drill bits can be customized as per customers’ requirements | |||

Application of carbide cutting tips

1, carbide cutting tips are brazed on percussion drill or electric drill or pneumatic drill to drill wall, ground, mining ect.

2, carbide cutting tips tips widely used for electric drill in special condition, also used for electric dill or pneumatic drill for building,geology and coal mining

3, carbide cutting tips suitable for harder rock or rock with hard stratum or metallic rock,

4, carbide cutting tips suitable for all kinds of cement drill bits

Production features of carbide cutting tips

1.HIP sintering ensures carbide cutting tips has good density and strength.

2.Removing carbide cutting tips surface stress and enhancing hardness by special process.

3. Nickel coating enhances the surface finish, wear resistance and welding property of products. It is suitable for auto welding electric drill or pneumatic drill.

![]()

Packing and delivery of carbide cutting tips

wrapped carbide cutting tips in plastic bottle to avoid carbide cutting tips to broke → put the carbide cutting tips in inner small carton box → put the inner box into outter carton and fill the carton with foamed plastic → wrap the carton with packaging tape → you can choose any delivery way such as DHL,TNT,UPS ect.

![]()

Company brief introduction

Strong production capacity. We own mature production technology, process, various TPA press, large tonnage of hydraulic press and HIP furnace, ensuring pressing quality and sintering capacity achieving 500KG per time. We can guarantee uniformity and stability of mass production.

Strong R&D team. Professional engineers serve for clients, recommending product and grades as per your applications. They also offer best after-sale service.

Strong Mould R&D team. They support customization of products as per requirements, and ensure high working efficiency and product quality.

Successful cooperation case: We cooperate with clients in domestic and abroad, and get good feedback from them.

![]()