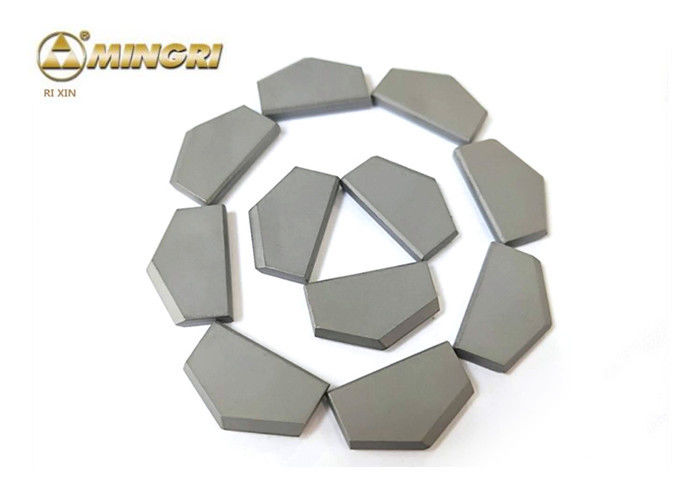

Concrete Tungsten Carbide Tips Customized

Product Details:

| Place of Origin: | China |

| Brand Name: | Rixin |

| Certification: | ISO9001:2008 |

| Model Number: | customized |

Payment & Shipping Terms:

| Minimum Order Quantity: | 10kg |

|---|---|

| Price: | USD + 32~62 + KG |

| Packaging Details: | cartons |

| Delivery Time: | 5-15 days |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 50+tons+per month |

|

Detail Information |

|||

| Features: | Super Quality / Long Using Life | Product Name: | SDS Hammer Carbide Tips |

|---|---|---|---|

| Keyword: | SDS Hammer Carbide Tips | Material: | Tungsten Carbide |

| Grade: | MR8-B | Application: | Drill Steel Reinforced Concrete Wall |

| Density: | 14.7 G/cm3 | Hardness: | 88.5 HRA |

| T.R.S: | 2700 MPa | ||

| Highlight: | tungsten carbide cutting tips,tungsten carbide tool tips,Customized Concrete Tungsten Carbide Tips |

||

Product Description

concrete masonry Wholesale carbide tips SDS hammer drill bit

advantage of SDS hammer carbide tips

| Product Name | SDS hammer carbide tips |

| Material | Tungsten Carbide |

| Color | Sliver gray |

| Standard | ISO |

| Material | K10 K15 K20 K30 K40 |

| Application | Widely used for drilling building,geology and coal mining and heavy rock |

Description of SDS hammer carbide tips

|

Grade |

|

|

|

Applications recommended | ISO Code |

|

|

|

|

|||

|

|

|

|

|

Suitable for harder rock or rock with hard stratum or metallic rock |

|

|

Other grades can be offered by customers' requirement

|

|||||

![]()

![]()

S type electric hammer dill bits:

| Specification | D mm | Tolerance | W mm | Tolerance | T mm | Tolerance | B° | A |

| 3 | 3 |

+0.35 +0.22 |

3.5 |

+0.2 0 |

1.0 |

+0 -0.1 |

20 | 0.2 |

| 4 | 4 | 4.5 | 1.2 | 0.3 | ||||

| 5 | 5 | 5.0 | 1.5 | 0.4 | ||||

| 6 | 6 | 5.7 | 1.4 | 0.5 | ||||

| 6.2 | 6.0 | 5.1 | 1.75 | 0.5 | ||||

| 6.5 | 6.5 | 5.3 | 1.6 | 0.5 | ||||

| 7 | 7 | 5.7 | 1.6 | 0.5 | ||||

| 8 | 8 |

+0.38 +0.22 |

6.3 | 1.8 | 0.6 | |||

| 8.5 | 8.5 | 6.5 |

+0.3 0 |

1.8 | 0.6 | |||

| 9 | 9 | 6.5 | 1.8 | 0.6 | ||||

| 10 | 10 | 7.3 | 2.0 | 0.7 | ||||

| 10.5 | 10.5 | 7.3 | 2.0 | 0.7 | ||||

| 12 | 12 | 8.0 | 2.2 | 0.8 | ||||

| 12.5 | 12.5 | 8.0 | 2.2 | 30 | 0.8 | |||

| 12.7 | 12.7 | 8.0 | 2.2 | 0.8 | ||||

| 14 | 14 |

+0.45 +0.26 |

9.0 | 2.6 | 1.0 | |||

| 15 | 15 | 10 |

+0.5 0 |

2.8 | 0.8 | |||

| 16 | 16 | 10 | 2.8 | 1.0 | ||||

| 17 | 17 | 10 | 2.8 | 1.0 | ||||

| 18 | 18 | 11 | 3.2 | 1.2 | ||||

| 19 | 19 |

+0.5 +0.28 |

11 | 3.2 | 1.2 | |||

| 20 | 20 | 13 | 3.2 | 1.3 | ||||

| 22 | 22 | 14 | 3.5 | 1.3 | ||||

| 24 | 24 | 15 | 4.0 | 1.3 | ||||

| 25 | 25 | 15 | 4.0 | 1.3 | ||||

| 26 | 26 | 15 | 4.5 | 1.6 | ||||

| 32 | 32 |

+0.55 +0.3 |

19.5 | 5.5 | 1.7 | |||

|

||||||||

Application of SDS hammer carbide tips

SDS hammer carbide tips are brazed on percussion drill or electric drill or pneumatic drill to drill wall, ground, mining ect.

SDS hammer carbide tips widely used for electric drill in special condition, also used for electric dill or pneumatic drill for building,geology and coal mining

SDS hammer carbide tips suitable for harder rock or rock with hard stratum or metallic rock,

SDS hammer carbide tips suitable for all kinds of cement drill bits

![]()

Production and test of SDS hammer carbide tips

1) SDS hammer carbide tips will start to prepare the RTP powder as per customer’s requirement with our wet-grinding machine

2) Before mass production of SDS hammer carbide tips, we need to do a trial pressing and sintering, and we check the appearances and the sizes of the samples with micrometer to ensure that the requirements of the drawings can be met before batch production

3) Bulk production ,press the raw materials to shape blanks,and SDS hammer carbide tips must be passed by semi finished inspection.

4) sinter blanks to finish (HIP) and finished products inspection to ensure the best quality and production capacity.

![]()

Packing and delivery of SDS hammer carbide tips

wrapped SDS hammer carbide tips in paper to avoid SDS hammer carbide tips to broke → put the SDS hammer carbide tips in inner small carton box → put the inner box into outter carton and fill the carton with foamed plastic → wrap the carton with packaging tape → you can choose any delivery way such as DHL,TNT,UPS ect.

![]()

Company brief introduction

230 workers, 8000 m2 non-dust workshop, 18 years experience , 10000 sets mould, 5 workshop included grinding powder workshop, pressing workshop, sintering workshop, processing workshop, mould production workshop, production capacity 50tons/month, well-known brand ”Ri Xin” has registered in Europe for 6 years , ISO, CE&FDA certificated, one hour reach Shanghai port, this is how we keep superior quality and competitive offers for global valued customers.

Our main products cover cold heading dies, wire drawing dies, strips and plates, saw tips, brazed tips, disc cutters, round rods, rock drilling bits and buttons, milling tools, also we can make all kinds of customized proposal to meet customers’ requirement.

![]()