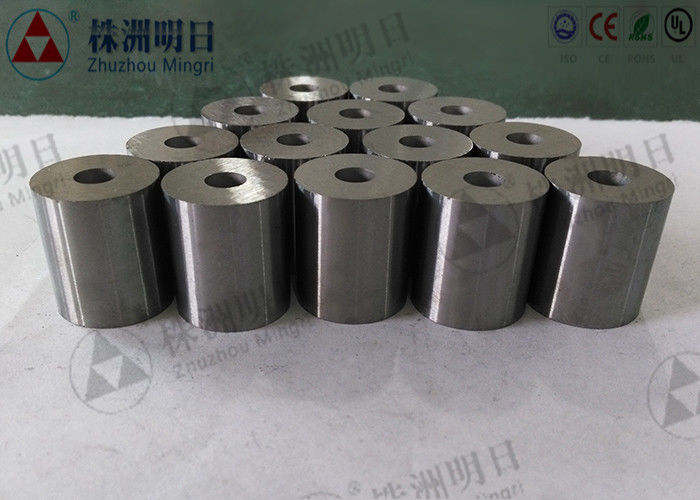

Customized Tungsten Carbide Die Battery Jars Punching Die Yg11 Yg15 Wc Cobalt

Product Details:

| Place of Origin: | ZHUZHOU,HUNAN,CHINA |

| Brand Name: | RI XIN |

| Certification: | ISO9001:2008 ISO14001:2004 |

| Model Number: | YG11,YG15,YG20,YG16C,YG18C,YG20C,YG22C,YG25C,GT55 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 5KG |

|---|---|

| Price: | Price varies as per grade,weight and size |

| Packaging Details: | First in small cartons filled with cotton, then in bigger cartons. |

| Delivery Time: | 7-20 Days depends on products |

| Payment Terms: | D/A, L/C, D/P, T/T |

| Supply Ability: | 50 Tons per month |

|

Detail Information |

|||

| Features: | High Hardness,Good Impact And Wear Resistance | Grade: | YG11,YG15,YG20,YG16C,YG18C,YG20C,YG22C,YG25C,GT55 |

|---|---|---|---|

| Application: | Cold Heading/Forging Die,Battery Jars Punching Die. | Material: | WC,Cobalt |

| Surface Treatment: | Blank,Grinding,Sand-blasting,Polishing | Service: | OEM,ODM,After-sales Service |

| Highlight: | tungsten carbide pellets,tungsten carbide tooling |

||

Product Description

CUSTOMIZED TUNGSTEN CARBIDE COLD HEADING DIES:

Descriptions:

1.Widely used in cold heading dies and forging dies.

2.Nonstandard sizes of carbide pellets as per customer requests.

3.All carbide pellets are strictly inspected by ultrasonic flaw detector to avoid ones with blowholes or cracks to ensure the quality.

4.Material:100%Virgin material with submicron grain size.

5.High wear resistance,high hardness and impact toughness.

6.We can provide blank or deep finished products with precision grinding and polishing.

Our advantages:

1.Strong R&D team. Professional engineers serve for clients, recommend product and grade as per your applications. We also offer after-sale service.

2.Strong Mould R&D team. We support product customization as per requirements, ensure high working efficiency and product quality.

3.Successful cooperation case: We cooperate with clients in domestic and abroad, and get good feedback from them.

Grade:

| Grade | Density g/cm3 |

T.R.S MPα |

Hardness HRA |

Properties & Applications | Approx Grades in China |

| A | 13.5 | 3000 | 83.5 | Good wear resistance and bending strength. It is often preferred by nut forming dies and high impact-resistantance dies. | — |

| YM11 | 14.4 | 2420 | 88.5 | Forming or stamping dies for metal powders and nonmetal powders. | YG11 |

| YM15 | 14.0 | 2500 | 87.5 | It is suitable for drawing steel tubes and rods under high compression ratio, manufactuing upsetting, punching and forging tools under large stress. | YG15 |

| YM20 | 13.5 | 2800 | 85.5 | It is suitable for manufacturing punching dies for watch parts, leaf spring of musical instruments, battery jars, small sized steel balls, screws, screw caps, etc. | YG20 |

| ML32 | 13.9 | 2750 | 85.5 | It is suitable for impact-resistant forging dies. | YG16C |

| ML36 | 13.7 | 2800 | 84.5 | It is suitable for impact-resistant forging dies, hot-forging dies and finishing rollers. | YG18C |

| ML40 | 13.5 | 2850 | 83.5 | It is suitable for wear resistantance or impact resistant dies. | YG20C ZL40.2 |

| ML50 | 13.3 | 2900 | 83.0 | It is suitable for nut forming dies and high impact-resistantance dies. | YG22C ZL40.5 |

| ML60 | 13.1 | 2950 | 82.5 | It is suitable for stainless screw dies and semifinishing rollers. | YG25C ZL40B |

| ML80 | 13.1 | 3050 | 83.4 | It is suitable for screw cap forming dies with high strength ( highest impact-resistant forging dies). | YG25C GT55 |

| Other grades of cemented carbide blanks for cold-forging dies may be offered as per customer requirements | |||||

Specifications:

Include but not limited to the following types.

![]()

Type |

Dinension |

Appllcable |

|||

| d | D | L Range of L |

|||

| BDP00710- | 0.7 | 10 | 12.0-20.0 | M1 | |

| BDP01010- | 1.0 | 10 | 12.0-20.0 | M1.5-M2 | |

| BDP01013- | 1.0 | 13 | 15.0-40.0 | M1.5-M2 | |

| BDP01213- | 1.2 | 13 | 15.0-40.0 | M1.5-M2 | |

| BDP01510- | 1.5 | 10 | 12.0-25.0 | M2 | |

| BDP01516- | 1.5 | 16 | 15.0-45.0 | M2 | |

| BDP01813- | 1.8 | 13 | 12.0-45.0 | M2.5 | |

![]()

![]()

![]()

![]()

![]()

![]()