Abrasion Resistance Tungsten Carbide Die Cold Heading Tools

Product Details:

| Place of Origin: | China |

| Brand Name: | Rixin |

| Certification: | CE ROHS UL ISO |

| Model Number: | YG16C |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1KG |

|---|---|

| Packaging Details: | Cartons |

| Delivery Time: | 5-15 days |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 50+tons+per month |

|

Detail Information |

|||

| Keyword: | Carbide Cold Heading Die | Material: | 100% Raw Material |

|---|---|---|---|

| Usage: | Impact-resistant Forging Dies | Density: | 13.9 |

| Component: | WC+CO | Tolerance: | As Per Your Requirment |

| Hardness: | 85.0 HRA | T.R.S: | 2750 MPa |

| Highlight: | tungsten carbide pellets,tungsten carbide tooling,Abrasion Resistance Tungsten Carbide Die |

||

Product Description

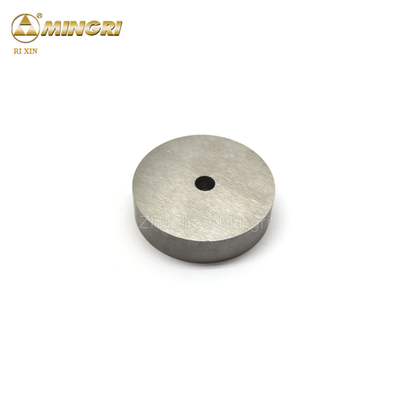

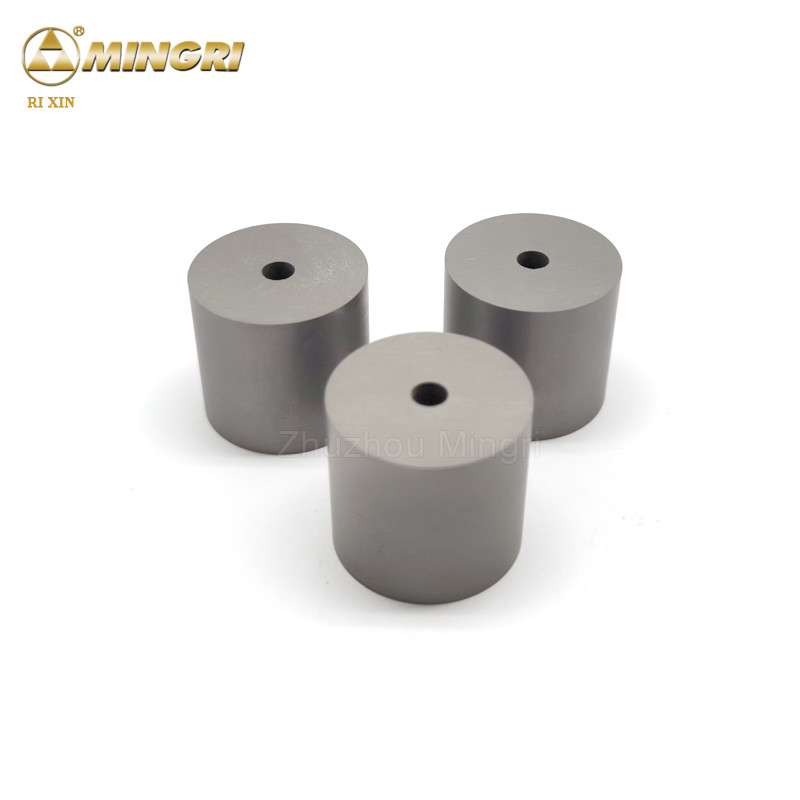

Screw Header Punches HIP sintering high stress resistance original tungsten carbide

Specification of Carbide Cold Heading Die

1. Size: We have hundreds of moudles available now.Different sizes offered.

2. High wear&corrosion&abrasive resistance.

3. Advanced producing equipment.

4. ISO9001:2008,ISO9001:14001 certificated.

5. YG11 YG15 YG20 YG16C YG18C YG20C YG22C YG25C YG25 grades available.

6. Types: dies for drawing metal wires, rods, tubes, plugs and non-standard dies.

| Grade | Density | Hardness HRA | T.R.S MPa | Performance&application recommended |

| YG20C | 13.5 | 83.0 | 2850 | It is suitable for wear resistant or impact resistant dies |

| YG22C | 13.3 | 82.0 | 2900 | It is suitable for nut forming dies and high impact-resistant dies |

| YG25C | 13.1 | 81.5 | 2950 | It is suitable for stainless scres dies and semifinishing rollers |

| ML80 | 13.1 | 83.0 | 3200 |

It is suitable for screw cap forming dies with high strength(highest impact-resistant forging dies) |

Application of Carbide Cold Heading Die

The tungsten carbide heading dies are used for cold punching and heading of srews and nuts, with high wear resistance and high toughness. Also, it is the ideal material in making non-ferrous metal, ferrous metal and other alloy.

Decription of Carbide Cold Heading Die

1,Cold heading die area is one of the main applications of tungsten carbide material. Heading dies usually can be divided into punching die and bushing die , used in cold heading, warm heading and hot heading technology situation.

2,Cold heading is a process technology which make the work piece transformation and the shape close to the finished product to the utmost extent in few processes. It is the milestone of modern mechining and automobile industry.

3,Why we need cold heading?

Cold heading improves the products'structure.

![]()

Production Test of Carbide Cold Heading Die

1, coercimeter

2, digital hardness tester

3, metallographic pre-grinding machine

4, metallographic microscope

5, chemical analysis

![]()

![]()

Why customers choosing us?

Zhuzhou Mingri Tungsten Carbide Co., Ltd. was established in May of 2001 with the investment of RMB 40 million. We have up-to-date production machine line and a lot of technicians.

Zhuzhou MingRi Cemented carbide co.,ltd is located in the tungsten carbide hometown , convenient transportation, from changsha airport just 40 minutes, Wuhan just 1.5 hour, from guangzhou just 2 hours. A favorable peripheral environment for cemented carbide manufacturing provides a natural barrier. Convenient traffic for tomorrow's internationalization laid a wide road.

We specialize in various of tungsten carbide products. Our products are sold to the UK, Europe, Japan, Korea, Taiwan area and Southeast Asia.

![]()