Customized made ground YF06 making solid carbide tools ISO14001 2004

Product Details:

| Place of Origin: | china |

| Brand Name: | Ri Xin |

| Certification: | ISO9001:2008 ISO14001:2004 |

| Model Number: | Various |

Payment & Shipping Terms:

| Minimum Order Quantity: | 5kg |

|---|---|

| Packaging Details: | First in small cartons filled with cotton, then in bigger cartons. |

| Delivery Time: | 7-20 days depending on the quantity |

| Supply Ability: | 30 ton per month |

|

Detail Information |

|||

| Product Name: | Customized Made High Quality Ground Solid Tungsten Carbide Rod | Material: | Tungsten Carbide, Cemented Carbide, Hard Metal, TC, Hard Alloy, Widia |

|---|---|---|---|

| Grade: | K10, K20, K30, K40, YG10X, YL10.2, YG13, YG12X, YG15 | Grain Size: | Medium Or Fine |

| Type: | Solid Carbide Rods, Rods With Double Helix Holes, Rods With Single Straight Hole, Rods With Two Straight Holes | Application: | End Mill, Drill, Punch, Mould, Burr |

| Highlight: | Cemented carbide rods,Tungsten Carbide Round Bar |

||

Product Description

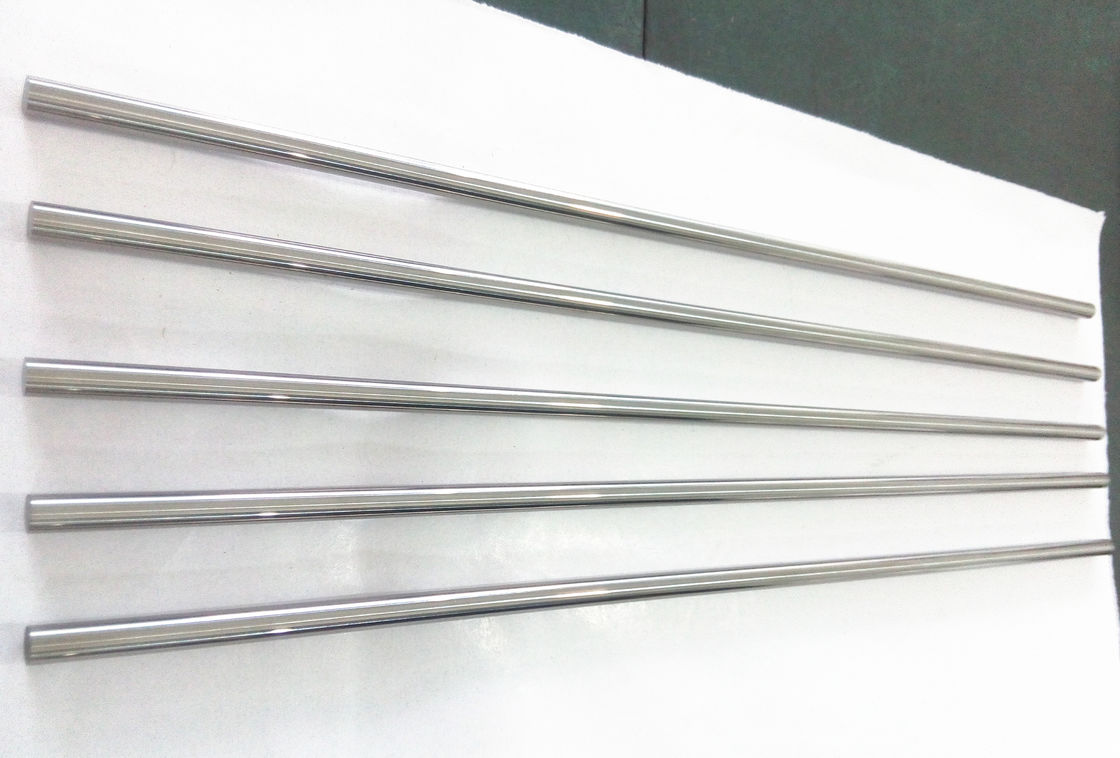

Customized made ground YF06 making solid carbide tools ISO14001 2004

1. Description of the tungsten carbide rods

Our tungsten carbide rod have been created with the application of precision and innovative techniques. These are widely demanded in the market for our tungsten carbide rods premium quality, long shelf life and excellent resistance properties. These are made available in standard as well as customized dimensions, depending upon the requirements of the customers. .

2. Gade of the tungsten carbide rods YG6 YG6X YG10X YL10.2

3. Our normal tolerance is H6. The highest tolerance our rod could reach is H4-H3

cemented carbide strips

Grade:

|

Grade |

Density |

T.R.S |

Hardness |

Properties & Applications |

|

YL50 |

13.86 |

2060 |

1095 |

It is suitable for manufacturing punching dies and tools. |

|

YU06 |

14.7 |

3000 |

2050 |

It is suitable for manufacturing milling cutters for machining PCB. It is also suitable for manufacturing various kinds of solid cemented carbide tools for machining glass fiber, wood, plastics, paper and brass, Al alloy etc. |

|

YU08 |

14.56 |

4000 |

1900 |

It is suitable for manufacturing micro-drills with diameter less than 0.8mm for machining PCB. It is also suitable for manufacturing various kinds of solid cemented carbide tools for machining glass fiber, wood, plastics, paper and brass, Al alloy etc. |

|

YU09 |

14.36 |

3900 |

1950 |

It is suitable for manufacturing micro-drills for machining PCB. It is also suitable for manufacturing various kinds of solid cemented carbide tools for machining glass fiber, wood, plastics, paper and brass, Al alloy etc. |

|

YU12 |

14.05 |

4000 |

1750 |

It is suitable for manufacturing solid cemented carbide tools for machining steels that are corrosion and heat resistant steel, stainless steel, titanium alloy, and non-ferrous metals. |

|

YF06 |

14.86 |

3800 |

1800 |

It is suitable for manufacturing drills with big diameters of 3.2-6.3mm for machining PCB, drills of 0.8-3.2mm and mills, and it is also suitable for making solid carbide tools for machining aluminum alloy, plastic, PTFE and compound materials, such as carbon fiber, etc. |

|

YF08 |

14.55 |

3900 |

1800 |

It is suitable for manufacturing micro-drills for machining PCB. It is also suitable for manufacturing various kinds of solid cemented carbide tools for machining glass fiber, wood, plastics, paper and brass, Al alloy, etc. |

|

YG6X |

14.8 |

1800 |

1550 |

It is suitable for manufacturing solid carbide tools and wear parts. |

|

YG8 |

14.6 |

2400 |

1400 |

It is suitable for manufacturing carbide core rods and wear parts. |

|

YL10.2 |

14.5 |

4000 |

1550 |

It is suitable for manufacturing various kinds of solid cemented carbide tools for machining heat-resistant alloys and Ti alloy etc. It is also suitable for manufacturing micro-drills for machining PCB. |

Size and drawing:

Solid carbide rod

![]()

|

(Unit):mm |

|||

|

Diameter |

Tolerance |

Length |

Tolerance |

|

D≤5 |

0-0.3 |

330<L |

0-6.0 |

|

5<D≤20 |

0-0.4 |

||

|

20<D |

0.1-0.6 |

|

310mm or 330mm |

(Unit):mm |

||

|

Diameter |

Tolerance |

Diameter |

Tolerance |

|

1.2 |

|

16.7 |

|

|

1.7 |

17.2 |

||

|

2.2 |

17.7 |

||

|

2.7 |

18.2 |

|

|

|

3.2 |

18.7 |

||

|

3.7 |

19.2 |

||

|

4.2 |

19.7 |

||

|

4.7 |

20.2 |

||

|

5.2 |

20.7 |

||

|

5.7 |

|

21.2 |

|

|

6.2 |

21.7 |

||

|

6.7 |

22.2 |

||

|

7.2 |

22.7 |

||

|

7.7 |

23.2 |

||

|

8.2 |

|

23.7 |

|

|

8.7 |

24.2 |

|

|

|

9.2 |

25.2 |

||

|

9.7 |

25.7 |

||

|

10.2 |

26.2 |

||

|

10.7 |

27.2 |

||

|

11.2 |

|

28.2 |

|

|

11.7 |

29.2 |

||

|

12.2 |

30.2 |

||

|

12.7 |

|

31.2 |

|

|

13.2 |

32.2 |

||

|

13.7 |

33.2 |

0.80 |

|

|

14.2 |

|

34.2 |

|

|

14.7 |

35.5 |

||

|

15.2 |

36.2 |

||

|

15.7 |

382 |

||

|

16.2 |

40.2 |

Zhuzhou MingRi Cemented carbide co.,ltd is located in the tungsten carbide hometown , convenient transportation, from changsha airport just 40 minutes, wuhan just 1.5 hour, from guangzhou just 2 hours. A favorable peripheral environment for cemented carbide manufacturing provides a natural barrier. Convenient traffic for tomorrow's internationalization laid a wide road.

We specialize in various of tungsten carbide products. Our products are sold to the UK, Europe, Japan, Korea, Taiwan area and Southeast Asia.

We strive for long-term business relationships with all customers, and look forward to being your first choice for your source of carbide.