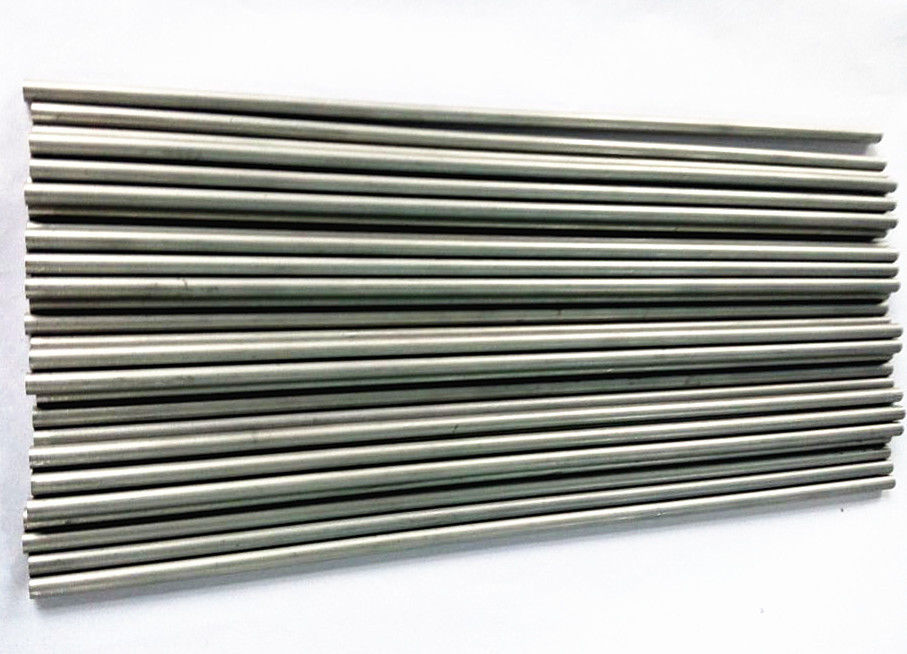

K10 K20 Cemented Tungsten Carbide Rod Medium or fine End mill

Product Details:

| Place of Origin: | china |

| Brand Name: | Ri Xin |

| Certification: | ISO9001:2008 ISO14001:2004 |

| Model Number: | Various |

Payment & Shipping Terms:

| Minimum Order Quantity: | 5kg |

|---|---|

| Packaging Details: | First in small cartons filled with cotton, then in bigger cartons. |

| Delivery Time: | 7-20 days depending on the quantity |

| Supply Ability: | 30 ton per month |

|

Detail Information |

|||

| Product Name: | K10 K20 K30 K40 Cemented Carbide Round Bar For Punch And Dies | Material: | Tungsten Carbide, Cemented Carbide, |

|---|---|---|---|

| Grade: | K10, K20, K30, K40, | Grain Size: | Medium Or Fine |

| Type: | Solid Carbide Rods, | Application: | End Mill, Drill, Punch, Mould, Burr |

| Highlight: | Cemented carbide rods,solid carbide rods |

||

Product Description

K10 K20 K30 K40 Cemented Carbide Round Bar Medium or fine End mill

Grade:

|

Grade |

Density |

T.R.S |

Hardness |

Properties & Applications |

|

YL50 |

13.86 |

2060 |

1095 |

It is suitable for manufacturing punching dies and tools. |

|

YU06 |

14.7 |

3000 |

2050 |

It is suitable for manufacturing milling cutters for machining PCB. It is also suitable for manufacturing various kinds of solid cemented carbide tools for machining glass fiber, wood, plastics, paper and brass, Al alloy etc. |

|

YU08 |

14.56 |

4000 |

1900 |

It is suitable for manufacturing micro-drills with diameter less than 0.8mm for machining PCB. It is also suitable for manufacturing various kinds of solid cemented carbide tools for machining glass fiber, wood, plastics, paper and brass, Al alloy etc. |

|

YU09 |

14.36 |

3900 |

1950 |

It is suitable for manufacturing micro-drills for machining PCB. It is also suitable for manufacturing various kinds of solid cemented carbide tools for machining glass fiber, wood, plastics, paper and brass, Al alloy etc. |

|

YU12 |

14.05 |

4000 |

1750 |

It is suitable for manufacturing solid cemented carbide tools for machining steels that are corrosion and heat resistant steel, stainless steel, titanium alloy, and non-ferrous metals. |

|

YF06 |

14.86 |

3800 |

1800 |

It is suitable for manufacturing drills with big diameters of 3.2-6.3mm for machining PCB, drills of 0.8-3.2mm and mills, and it is also suitable for making solid carbide tools for machining aluminum alloy, plastic, PTFE and compound materials, such as carbon fiber, etc. |

|

YF08 |

14.55 |

3900 |

1800 |

It is suitable for manufacturing micro-drills for machining PCB. It is also suitable for manufacturing various kinds of solid cemented carbide tools for machining glass fiber, wood, plastics, paper and brass, Al alloy, etc. |

|

YG6X |

14.8 |

1800 |

1550 |

It is suitable for manufacturing solid carbide tools and wear parts. |

|

YG8 |

14.6 |

2400 |

1400 |

It is suitable for manufacturing carbide core rods and wear parts. |

|

YL10.2 |

14.5 |

4000 |

1550 |

It is suitable for manufacturing various kinds of solid cemented carbide tools for machining heat-resistant alloys and Ti alloy etc. It is also suitable for manufacturing micro-drills for machining PCB. |

Size and drawing:

Solid carbide rod

![]()

|

(Unit):mm |

|||

|

Diameter |

Tolerance |

Length |

Tolerance |

|

D≤5 |

0-0.3 |

330<L |

0-6.0 |

|

5<D≤20 |

0-0.4 |

||

|

20<D |

0.1-0.6 |

|

310mm or 330mm |

(Unit):mm |

||

|

Diameter |

Tolerance |

Diameter |

Tolerance |

|

1.2 |

|

16.7 |

|

|

1.7 |

17.2 |

||

|

2.2 |

17.7 |

||

|

2.7 |

18.2 |

|

|

|

3.2 |

18.7 |

||

|

3.7 |

19.2 |

||

|

4.2 |

19.7 |

||

|

4.7 |

20.2 |

||

|

5.2 |

20.7 |

||

|

5.7 |

|

21.2 |

|

|

6.2 |

21.7 |

||

|

6.7 |

22.2 |

||

|

7.2 |

22.7 |

||

|

7.7 |

23.2 |

||

|

8.2 |

|

23.7 |

|

|

8.7 |

24.2 |

|

|

|

9.2 |

25.2 |

||

|

9.7 |

25.7 |

||

|

10.2 |

26.2 |

||

|

10.7 |

27.2 |

||

|

11.2 |

|

28.2 |

|

|

11.7 |

29.2 |

||

|

12.2 |

30.2 |

||

|

12.7 |

|

31.2 |

|

|

13.2 |

32.2 |

||

|

13.7 |

33.2 |

0.80 |

|

|

14.2 |

|

34.2 |

|

|

14.7 |

35.5 |

||

|

15.2 |

36.2 |

||

|

15.7 |

382 |

||

|

16.2 |

40.2 |

Usage

End mills:

![]()

Package:

![]()