Coal Mining shield cutter TBM wear resistance High speed cutting

Product Details:

| Place of Origin: | Zhuzhou Hunan China |

| Brand Name: | none |

| Certification: | ISO9001:2008 ISO9001:14001 |

| Model Number: | many |

Payment & Shipping Terms:

| Minimum Order Quantity: | 5KG |

|---|---|

| Packaging Details: | Packed in carton firstly, and then reinforced with wooden or paper case for outer packing |

| Delivery Time: | 2-3 weeks |

| Supply Ability: | 30Tons/month |

|

Detail Information |

|||

| Product Name: | Shield Cutter | Material: | WC+Co |

|---|---|---|---|

| Grade: | YG8C, YG11C, YG13C YG15C | Useage: | Minling,coal Mining , Oil Drilling , |

| Type: | OEM&ODM | ||

| Highlight: | tbm disc cutter,metal disc cutter |

||

Product Description

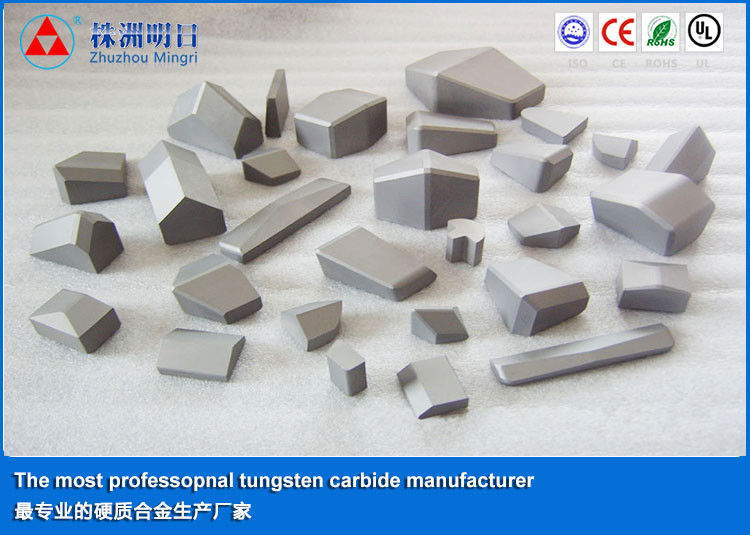

Coal Mining shield cutter TBM wear resistance High speed cutting

Description:

The shield & TBM cutter is applied to tunnel through rock no matter what kinds of ground

conditions for under road tunnel construction and subway tunnel construcation. Our company

can manufacture the tips of tunnel boring machines with high quality and competitive

price, also can customized according to the customer's requirement.

![]()

Grade and Applications:

|

Grade |

Density |

T.R.S |

Hardness |

Performance & application recommended |

|

g/cm3 |

MPα |

HRA |

||

|

MK4 |

15.1 |

1800 |

90.0 |

Mainly used as small buttons for percussion bits to cut soft and medium hard formations. |

|

MK6 |

14.9 |

2000 |

90.5 |

For coring crowns, electric coal drill bits, coal cutting picks, oil cone bits and scraping knife bits, usd in geological prospecting, coal mining and oil well boring. |

|

MK8 |

14.7 |

2400 |

89.7 |

For coring crowns, electric coal drill bits, coal cutting picks, cone drill bits and scraping knife bits, used in geological prospecting, coal mining and oil well boring. |

|

MK10 |

14.7 |

2450 |

88.5 |

Mostly used as the buttons of small and mediumsized percussion bits and as the inserts of rotary prospecting bits to cut soft and medium hard formations. |

|

MK15 |

14.6 |

2450 |

87.8 |

Suitable to strips, conical buttons for rotary percussion-resistant, geological prospecting buttons, cut soft and medium hard formations. |

|

MK20 |

14.4 |

2550 |

87.0 |

Primarily for the buttons and inserts of rotary percussion bits to cut medium-hard and hard formations. |

|

MK25 |

14.5 |

2600 |

87.5 |

Primarily for the buttons and inserts of rotary percussion bits to cut medium hard and very hard formations. |

|

MK30 |

14.4 |

2600 |

87.0 |

Largely for the inserts and buttons of percussion bits and tricone bits to cut medium-hard, hard, and very hard formations. |

|

MK40 |

14.2 |

2650 |

86.5 |

Predominatly for the buttons of tricone bits and inserts of rotary percussion bits to cut hard and vey hard formations. |

|

MK50 |

14.0 |

2700 |

86.0 |

For oil cone drill bits, for medium soft and medium -hard rocks. |

|

MK60 |

14.0 |

2500 |

87.0 |

Good strength and less wear resistance, for bits of rotary hammer rock drills and heavy rock drills, for hard and very hard rocks. |

Other grades may be offered by customers' requirements

Competitive Advantage:

1. Free sample

2. Direct factory produce and sale

3. All kinds of grades are available

4. Custom made available

5. Precision processing and strict product inspection

6. Advanced Equipment and professional technicians

7. Gurantee the bulk quality are in accordance with the samples

8. ISO 9001-2008,ISO 14001-2004 Quality Control System

9. 100% virgin tungsten carbide powder

10. High speed cutting, wears well & long service life

11. High hardness, high strength, wear resistance

12. 12years professional experience

Zhuzhou Mingri Cemented Carbide Co., Ltd.

Located in Liyu Industrisl Area, Zhuzhou City, Tianyuan District, Hunan Province, Zhuzhou Mingri Cemented Carbide Co., Ltd was established in May of 2001 with the investment of RMB 40 million. We own up-to-date production line, advanced equipment, lots of technicians. We have passed ISO 9001:2008,ISO 9001:14001. And we have been always trying our best to provide our customers with high quality , best price and satisfactory services.

![]()

We specialize in series of tungsten carbide products, such ascold forging die cores, brazed tips, disc cutters, plates and boards, saw tips, round rods, rock drilling bits and buttons, milling tools, geological exploration drill tools and so on. Our production are exported to UK, European, Japan, Taiwan and South-east Asia etc.

You` re welcome to have a visit to our factory!

All varieties

Provide a comprehensive stamping precision metal strip material, gradually precision stamping one-stop shopping;

Provide comprehensive domestic and imported grades of metal strips of different products to meet the needs of different customers and different quality.

Quick delivery

200 tons of standing stock to ensure adequate supply;

6 precision sub-production lines run 24 hours;

Taiwan vans at you life, deal with the urgent needs of our customers.

Good service

18 professional sales engineer to provide a full range of alloy selection of technical and sales support materials;

Minimum quantity, flexibility to meet customers needs at different stages.

Excellent quality

Through ISO9001: 2008 quality system and ISO9001: 14001 Environmental System Certification;

Hunan, with all the most advanced testing equipment, strict quality control for the customer;

Customized ERP sophisticated control systems, strict to ensure the production, delivery accuracy.

Improve marketing and service network

The company's marketing and service network all over the country, the product quality by the majority of users praise. Including in Europe and the United States, including the permanent sale of the company's overseas sales network covering more than 70 countries worldwide, products are exported to all continents.