Customized cemented carbide Tbm Disc Cutter for tunnel boring machine

Product Details:

| Place of Origin: | Zhuzhou Hunan China |

| Brand Name: | none |

| Certification: | ISO9001:2008 ISO9001:14001 |

| Model Number: | many |

Payment & Shipping Terms:

| Minimum Order Quantity: | 5KG |

|---|---|

| Packaging Details: | Packed in carton firstly, and then reinforced with wooden or paper case for outer packing |

| Delivery Time: | 2-3 weeks |

| Supply Ability: | 30Tons/month |

|

Detail Information |

|||

| Product Name: | Shield Cutter | Material: | WC+Co |

|---|---|---|---|

| Surface: | Unground Or Ground | Grade: | YG8C, YG11C, YG13C YG15C |

| Grain Size: | Coarse | Type: | OEM&ODM |

| Highlight: | tbm disc cutter,shield cutter tipe |

||

Product Description

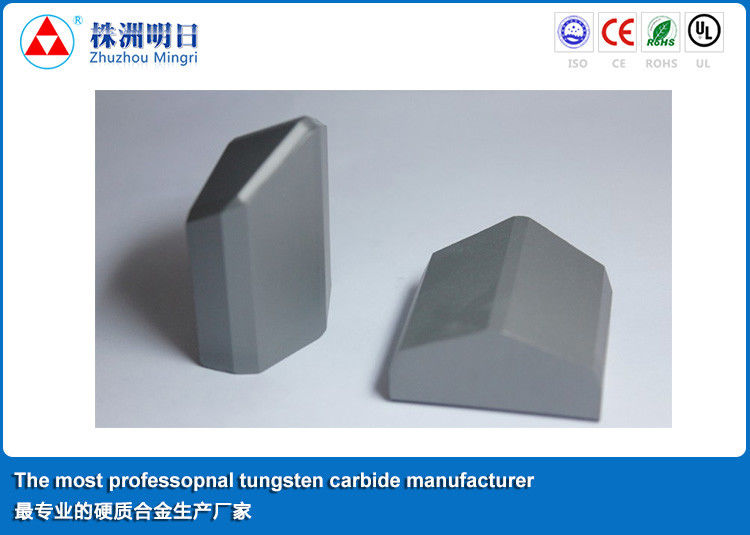

Customized cemented carbide Tbm Disc Cutter for tunnel boring machine

Description:

A tunnel boring machine (TBM) is a machine used to excavate tunnels with a circular cross section

through a variety of soil and rock strata. There have a very big circle blade in the front of tunnel boring

machine equipped with various kinds of cutters, in order to promote stable and longer lasting life of

application, we have research and developed special tungsten carbide materials suited to your application.

The TBM technology is mainly used in underground ming and traffic tunnelling like metro, railway and

road tunneling.

![]()

![]()

Grade and Applications:

|

Grade |

Density |

T.R.S |

Hardness |

Performance & application recommended |

|

g/cm3 |

MPα |

HRA |

||

|

MK4 |

15.1 |

1800 |

90.0 |

Mainly used as small buttons for percussion bits to cut soft and medium hard formations. |

|

MK6 |

14.9 |

2000 |

90.5 |

For coring crowns, electric coal drill bits, coal cutting picks, oil cone bits and scraping knife bits, usd in geological prospecting, coal mining and oil well boring. |

|

MK8 |

14.7 |

2400 |

89.7 |

For coring crowns, electric coal drill bits, coal cutting picks, cone drill bits and scraping knife bits, used in geological prospecting, coal mining and oil well boring. |

|

MK10 |

14.7 |

2450 |

88.5 |

Mostly used as the buttons of small and mediumsized percussion bits and as the inserts of rotary prospecting bits to cut soft and medium hard formations. |

|

MK15 |

14.6 |

2450 |

87.8 |

Suitable to strips, conical buttons for rotary percussion-resistant, geological prospecting buttons, cut soft and medium hard formations. |

|

MK20 |

14.4 |

2550 |

87.0 |

Primarily for the buttons and inserts of rotary percussion bits to cut medium-hard and hard formations. |

|

MK25 |

14.5 |

2600 |

87.5 |

Primarily for the buttons and inserts of rotary percussion bits to cut medium hard and very hard formations. |

|

MK30 |

14.4 |

2600 |

87.0 |

Largely for the inserts and buttons of percussion bits and tricone bits to cut medium-hard, hard, and very hard formations. |

|

MK40 |

14.2 |

2650 |

86.5 |

Predominatly for the buttons of tricone bits and inserts of rotary percussion bits to cut hard and vey hard formations. |

|

MK50 |

14.0 |

2700 |

86.0 |

For oil cone drill bits, for medium soft and medium -hard rocks. |

|

MK60 |

14.0 |

2500 |

87.0 |

Good strength and less wear resistance, for bits of rotary hammer rock drills and heavy rock drills, for hard and very hard rocks. |

Other grades may be offered by customers' requirements

Competitive Advantage:

1. Expertise in tungsten carbide for 15 years, we can assit you in choosing the optimum grade for your job.

2. We produce only with advanced tungsten carbide material to ensure high level of quality

3. You're guarranteed to find the right one for your application with various grade and types available

4. All our product are in-house made under strict quality controlled conditions.

![]()

1. All raw materials are tested in terms of density, hardness and T.R.S before use.

2. Every piece of product goes through in-process and final inspection.

3. Every batch of product can be traced.

4. 100% of our products pass final inspection before being put on the market.

![]()