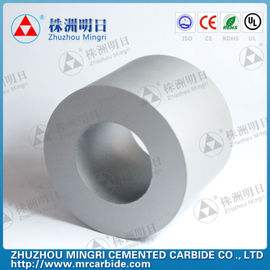

Cemented Carbide Cold Heading Die YG20C YG22C YG25C

Product Details:

| Place of Origin: | china |

| Brand Name: | Ri Xin |

| Certification: | SO9001:2008 ISO14001:2004 |

| Model Number: | Various |

Payment & Shipping Terms:

| Minimum Order Quantity: | 5kg |

|---|---|

| Packaging Details: | First in small cartons filled with cotton, then in bigger cartons. |

| Delivery Time: | 7-20 days depending on the quantity |

| Supply Ability: | 30 ton per month |

|

Detail Information |

|||

| Product Name: | YG20C YG22C YG25C Cemented Carbide Cold Heading Die | Material: | Tungsten Carbide, Cemented Carbide, Hard Metal |

|---|---|---|---|

| Grade: | YG20C YG22C YG25C GT40 GT55 | Application: | Cold Heading, Cold Forging, Cold Stamping, Cold Pressing, Cold Punching, Bolt/nut Forming |

| Surface: | Sintered Blank, Ground, Polished | ||

| Highlight: | YG22C Cold Heading Die,YG20C Cold Heading Die,YG20C Cemented Carbide Die |

||

Product Description

1. Description:

1.Cemented carbide pellets are widely used in cold heading dies and punching dies

for manufacturing nuts, bolts and many other products.

2.The grade GT55/YG25C is the most widely used material in making carbide pellets.

It has excellent properties which lead to good performance and long service time.

3.Except for the standard sizes, nonstandard sizes of carbide pellets

can also be produced according to customer's requirements.

4.All carbide pellets inspected strictly with ultrasonic flaw detector

to avoid ones with blowholes or cracks leaving the factory.

2. Applications:

Cemented carbide pellets are widely used in cold heading dies and punching dies

for maufacturing nuts, screw caps, bolts, cans and many other products.

3. Grade

| Grade | Density g/cm3 |

T.R.S MPα |

Hardness HRA |

Properties & Applications | Approx Grades in China |

| A | 13.5 | 3000 | 83.5 | Good wear resistance and bending strength. It is often preferrd by nut forming dies and high impact-resistant dies. | — |

| YM11 | 14.4 | 2420 | 88.5 | Forming or stamping dies for metal powders and nonmetal powders. | YG11 |

| YM15 | 14.0 | 2500 | 87.5 | It is suitable for drawing steel tubes and rods under high compression ratio, manufactuing upsetting, punching and forging tools under large stress. | YG15 |

| YM20 | 13.5 | 2800 | 85.5 | It is suitable for manufacturing punching dies for watch parts, leaf spring of musical instruments, battery jars, small sized steel balls, screws, screw caps, etc. | YG20 |

| ML32 | 13.9 | 2750 | 85.5 | It is suitable for impact-resistant forging dies. | YG16C |

| ML36 | 13.7 | 2800 | 84.5 | It is suitable for impact-resistant forging dies, hot-forging dies and finishing rollers. | YG18C |

| ML40 | 13.5 | 2850 | 83.5 | It is suitable for wear resistant or impact resistant dies. | YG20C ZL40.2 |

| ML50 | 13.3 | 2900 | 83.0 | It is suitable for nut forming dies and high impact-resistant dies. | YG22C ZL40.5 |

| ML60 | 13.1 | 2950 | 82.5 | It is suitable for stainless screw dies and semifinishing rollers. | YG25C ZL40B |

| ML80 | 13.1 | 3050 | 83.4 | It is suitable for screw cap forming dies with high strength ( highest impact-resistant forging dies). | YG25C GT55 |

| Other grades of cemented carbide blanks for cold-forging dies may be offered by customers' requirements | |||||

4. Specifications:

Including but not limited to the following types.

![]()

|

|

|

|

|||

|

d |

D |

L |

|||

|

BDP00710- |

0.7 |

10 |

12.0-20.0 |

M1 |

|

|

BDP01010- |

1.0 |

10 |

12.0-20.0 |

M1.5-M2 |

|

|

BDP01013- |

1.0 |

13 |

15.0-40.0 |

M1.5-M2 |

|

|

BDP01213- |

1.2 |

13 |

15.0-40.0 |

M1.5-M2 |

|

|

BDP01510- |

1.5 |

10 |

12.0-25.0 |

M2 |

|

|

BDP01516- |

1.5 |

16 |

15.0-45.0 |

M2 |

|

|

BDP01813- |

1.8 |

13 |

12.0-45.0 |

M2.5 |

|

|

BDP01816- |

1.8 |

16 |

20.0-45.0 |

M2.5 |

|

|

BDP02113- |

2.1 |

13 |

15.0-30.0 |

M3 |

|

|

BDP02116- |

2.1 |

16 |

25.0-45.0 |

M3 |

|

|

BDP02316- |

2.3 |

16 |

15.0-45.0 |

M3 |

|

|

BDP02522- |

2.5 |

22 |

20.0-60.0 |

M3 |

|

|

BDP02813- |

2.8 |

13 |

15.0-30.0 |

M4 |

|

|

BDP02816- |

2.8 |

16 |

25.0-40.0 |

M4 |

|

|

BDP02818- |

2.8 |

18 |

20.0-50.0 |

M4 |

|

|

BDP02820- |

2.8 |

20 |

20.0-50.0 |

M4 |

|

|

BDP02822- |

2.8 |

22 |

20.0-60.0 |

M4 |

|

|

BDP02825- |

2.8 |

25 |

20.0-60.0 |

M4 |

|

|

BDP03216- |

3.2 |

16 |

15.0-45.0 |

M4 |

|

|

BDP03218- |

3.2 |

18 |

15.0-50.0 |

M4 |

|

|

BDP03616- |

3.6 |

16 |

20.0-50.0 |

M5 |

|

|

BDP03618- |

3.6 |

18 |

20.0-60.0 |

M5 |

|

|

BDP03822- |

3.8 |

22 |

20.0-40.0 |

M5 |

|

|

BDP03830- |

3.8 |

30 |

50.0-60.0 |

M5 |

|

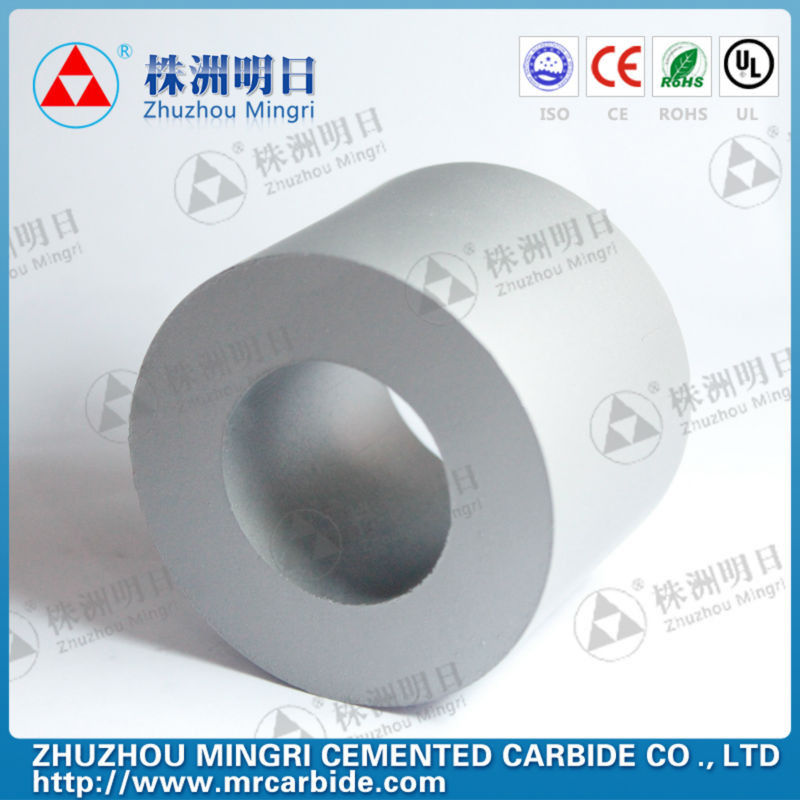

5. Package

![]()