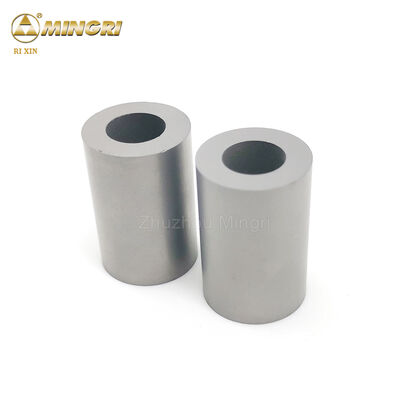

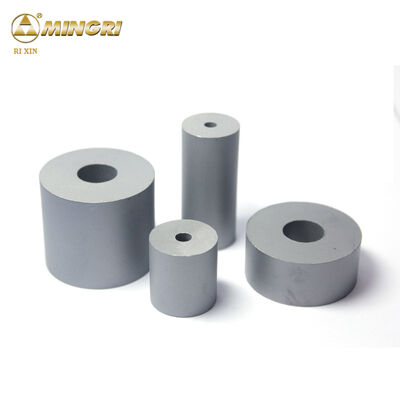

HIP Sintered Tungsten Carbide Die with High Bending Strength for Customized OEM Forging and Pellet Molds

Product Details:

| Place of Origin: | Hunan, China |

| Brand Name: | RIXIN |

| Model Number: | As require |

Payment & Shipping Terms:

| Minimum Order Quantity: | 10 |

|---|---|

| Price: | $1.88 |

|

Detail Information |

|||

| Overall Length: | 105mm | Width: | 35mm |

|---|---|---|---|

| Surface Finish: | Polished, Sand-blasted, Grinding, Polishing | Shape: | Cylindrical |

| Cut Type: | Double Cut | Material Composition: | WC+Cobalt |

| Grade Options: | YG20, YG20C, YG22C, YG25C, GT55, ML40, ML100 | TRS: | > 3000 N/mm3 |

| Hardness: | 85-92HRA | Outer Diameter: | 10-100mm |

| Inner Diameter: | 2-30mm | Length Range: | 10-60mm |

| Density Range: | 13.1-14.4 G/cm3 | Bending Strength: | 2800-3100 MPα |

| Impact Resistance: | High | ||

| Highlight: | HIP Sintered Tungsten Carbide Die,High Bending Strength Carbide Forging Die,Customized OEM Carbide Pellet Mold |

||

Product Description

Product Overview

HIP sintered Widia cemented tungsten carbide forging dies and polished pellet molds offering high bending strength and cylindrical customization for OEM applications.

Product Specifications

| Item | Tungsten carbide die |

| Grade | YG6, YG8, YG11, YG12, YG15, YG20, YG20C, YG22C, YG25C, GT55, ML40, ML100 |

| Sizes | Standard or customized |

| Brand | Rixin |

| Country of Origin | Zhuzhou, China |

| Usage | Cold heading die, forging mold, cold forming die, extrusion die, press mold, mould parts, die casting mould, punch dies, wire drawing die, machine mold, progressive die, trimming die, etc. |

Key Features

- Tungsten carbide die blanks are widely used for making finished die casting mould, punch dies, wire drawing die, machine mold, progressive die, extrusion die, press mold, mould parts, trimming die, cold heading die, forging mold, and cold forming die

- Extensive stock of available moulds for various sizes of carbide dies, saving significant costs for customers

- Wide range of stable grades for carbide dies with highest cost performance compared to Kennametal, Cbcarbide

Grade Specifications and Applications

| Grade | Density g/cm³ | T.R.S MPα | Hardness HRA | Properties & Applications | Approx Grades in China |

|---|---|---|---|---|---|

| A | 13.5 | 3000 | 83.5 | Good wear resistance and bending strength. Preferred for nut forming dies and high impact-resistant dies. | -- |

| YM11 | 14.4 | 2420 | 88.5 | Forming or stamping dies for metal powders and non-metal powders. | YG11 |

| YM15 | 14.0 | 2500 | 87.5 | Suitable for drawing steel tubes and rods under high compression ratio, manufacturing upsetting, punching and forging tools under large stress. | YG15 |

| YM20 | 13.5 | 2800 | 85.5 | Suitable for manufacturing punching dies for watch parts, leaf spring of musical instruments, battery jars, small sized steel balls, screws, screw caps, etc. | YG20 |

| ML32 | 13.9 | 2750 | 85.5 | Suitable for impact-resistant forging dies. | YG16C |

| ML36 | 13.7 | 2800 | 84.5 | Suitable for impact-resistant forging dies, hot-forging dies and finishing rollers. | YG18C |

| ML40 | 13.5 | 2850 | 83.5 | Suitable for wear resistant or impact resistant dies. | YG20C ZL40.2 |

| ML50 | 13.3 | 2900 | 83.0 | Suitable for nut forming dies and high impact-resistant dies. | YG22C ZL40.5 |

| ML60 | 13.1 | 2950 | 82.5 | Suitable for stainless screw dies and semifinishing rollers. | YG25C ZL40B |

| ML80 | 13.1 | 3050 | 83.4 | Suitable for screw cap forming dies with high strength (highest impact-resistant forging dies). | YG25C GT55 |

| ML100 | 13.1 | 3100 | 84 | Suitable for screw cap forming dies with high strength (highest impact-resistant forging dies). | GT55 plus |

Other grades of cemented carbide blanks for cold-forging dies may be offered by customers' requirements.

Dimensions and Types

OD: 10-100mm

ID: 2-30mm

Length: 10-60mm

Other sizes can be offered according to customers requirements.

Packaging and Delivery

| Packing | Paper + paper boxes + exported wooden cartons or paper cases. As a manufacturer, we can provide any kinds of package as buyer's requirement. |

| Shipping | UPS, TNT, EMS, Fedex, DHL, or as you request. |

| Delivery | 7-10 days after confirming all details. |

Main Products

We specialize in all kinds of tungsten carbide profiles and dies, cutting tools, mining tools, wear parts and all kinds of non-standard customized tool parts with high performance in the industry.

Company Information

Zhuzhou Mingri Cemented Carbide Co., Ltd was established in 2001 with the investment of 10 million dollars, area of 33300 square meters and 160 staffs. We have obtained 35 patents in invention, utility model and design, and passed ISO9001:2015 Certification in quality and GB/T 24001-2004/ISO 14001:2004 Certification in environment. We offer all kinds of high quality tungsten carbide products and technical services to all clients. Our products are exported to US, Europe, Japan, Taiwan and South-east Asia etc. We have won support and trust from customers both home and abroad.

Workshop Facilities

We have powder mixing, pressing, sintering, finishing, surface treatment, mould design workshops and physical and chemical labs for inspection. We have hundreds of updated equipments to ensure monthly capacity of 50 tons and excellent quality.

Quality Assurance

All products undergo strict ultrasonic inspection and only those without defects such as pores are shipped out. High density, high wear & impact resistance ensure long lifetime performance.

Team and Industry Presence

Contact Information

Want to Know more details about this product