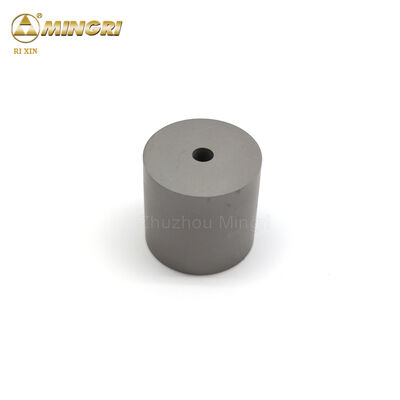

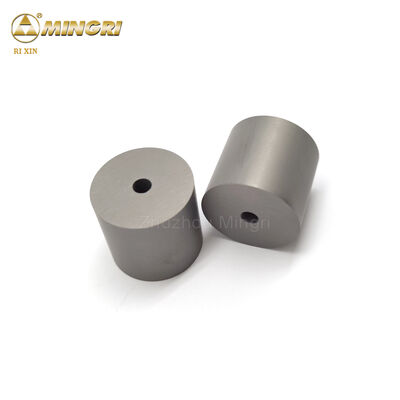

GT55 Customized OEM Tungsten Carbide Die 100% Virgin Material ISO9001 Certified with 3-Year Warranty

Product Details:

| Place of Origin: | Hunan, China |

| Brand Name: | RIXIN |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | $5-50 |

|

Detail Information |

|||

| Material: | 100% Virgin Tungsten Carbide | Color: | Silvery Grey |

|---|---|---|---|

| Surface Treatment: | Sand Blasting, Grinding | Density: | 14.4 G/cm3 (YG11) |

| Hardness: | 88.5 HRA (YG11) | Tensile Strength: | 2420 Mpa (YG11) |

| Die Blank Diameter: | 10-16 Mm | Die Blank Length: | 15-40 Mm |

| Tolerance: | +/-0.05 Mm | Production Capacity: | 50 Tons/month |

| Sintering Method: | Vacuum Sintering, HIP | Grade Options: | YG11, YG15, YG20, YG16C, YG18C, YG20C, YG22C, YG25C |

| Customization Support: | OEM, ODM | Size Customization: | As Per Requirement |

| Grinding Tolerance: | +/-0.05 Mm | ||

| Highlight: | 100% Virgin Tungsten Carbide Die,ISO9001 Certified Carbide Die,3-Year Warranty Fastener Die |

||

Product Description

- Zhuzhou Mingri maintains the richest inventory of carbide punch dies from Zhuzhou manufacturers

- 20 years of stable customer relationships and industry experience

- State-of-the-art tooling facilities and production capabilities

- Largest production capacity with fastest delivery times

- Comprehensive testing equipment for all specifications

- Reliable after-sales service and technical support

| Grade | Density g/cm³ | Hardness HRA | T.R.S MPa | Performance & Application |

|---|---|---|---|---|

| YG11 | 14.4 | 88.5 | 2420 | Forming or stamping dies for metal powders and nonmetal powders |

| YG15 | 14.0 | 87 | 3000 | Drawing steel tubes and rods under high compression ratio, manufacturing upsetting, punching and stamping tools under large stress |

| YG20 | 13.5 | 85.5 | 2800 | Manufacturing punching dies for watch parts, leaf spring of musical instrument, battery jars, small sized steel balls, screws, screw caps |

| YG16C | 13.9 | 85 | 2750 | Impact-resistant forging dies |

| YG18C | 13.7 | 84 | 2800 | Impact-resistant forging dies, hot-forging dies and finishing rollers |

| YG20C | 13.5 | 83 | 2850 | Wear resistant or impact resistant dies |

| YG22C | 13.3 | 82 | 2900 | Nut forming dies and high impact-resistant dies |

| YG25C | 13.1 | 81.5 | 2950 | Stainless screw dies and semi-finishing rollers |

| Other grades and sizes available per customer requirements | ||||

| TYPE | d (mm) | D (mm) | L (mm) |

|---|---|---|---|

| BD0131015 | 10 | 1.3 | 15 |

| BD0171020 | 10 | 1.7 | 20 |

| BD0171230 | 12 | 1.7 | 30 |

| BD0211230 | 12 | 2.1 | 30 |

| BD0211630 | 16 | 2.1 | 30 |

| BD0241015 | 10 | 2.4 | 15 |

| BD0241225 | 12 | 2.4 | 25 |

| BD0291425 | 14 | 2.9 | 35 |

| BD0291640 | 16 | 2.9 | 40 |

| … | … | … | … |

- Carbide precision tooling and machine components

- Fastener industry applications

- Bearing industry components

- Forming tools and manufacturing equipment

- Wear-resistant parts and components

- Standard, impact, and trapped extrusion applications

- Segmented carbide wafer assemblies

- Segmented carbide die inserts and assemblies

1. Upon order confirmation, we prepare RTP powder using wet-grinding machines according to customer specifications.

2. Trial pressing and sintering with each mold, followed by comprehensive inspection using micrometers and projectors to ensure drawing requirements are met.

3. Bulk production with raw materials pressed into shape blanks, all passing semi-finished inspection.

4. Sintering blanks to finish (HIP) with finished product inspection. Our facility includes 10 vacuum sintering furnaces and 2 HIP units to ensure optimal quality and production capacity.

5. Final processing includes cleaning/tumbling for improved appearance and grinding to tolerance of +/-0.05mm per customer requirements.

1. Individual paper wrapping to prevent damage

2. Secure placement in inner carton boxes

3. Outer carton packaging with foam plastic cushioning

4. Reinforced packaging tape sealing

5. Flexible shipping options including DHL, TNT, UPS and other carriers

Our facility employs 230 workers across an 8,000 m² non-dust workshop with 10,000 sets of molds. Monthly production capacity reaches 50 tons with comprehensive facilities including grinding powder, pressing, sintering, processing, and mold production workshops.

The well-known "Ri Xin" brand is registered in Europe, ISO and CE certified, with convenient access to Shanghai port for efficient global distribution.

Our product portfolio includes cold heading dies, wire drawing dies, strips and plates, saw tips, brazed tips, disc cutters, round rods, rock drilling bits and buttons, milling tools, plus customized solutions to meet specific customer requirements.

- Alibaba Trade Assurance protection for buyer benefits with 100% payment return if contract terms are not met

- 21 years of manufacturing expertise in carbide punch dies

- Continuous research and development for diverse types and sizes

- Global customer base with positive feedback and reviews from multiple countries