Grade GT40 GT50 GT55 Tungsten Carbide Cold Heading Die with Polished Surface and Customizable OEM for Steel & Stainless Steel Nibs

Product Details:

| Place of Origin: | Hunan, China |

| Brand Name: | rixin |

| Certification: | ISO9001:2008,ISO9001:14001 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | $52 |

|

Detail Information |

|||

| Material: | Cemented Carbide | Material Grade: | YG15/20C/YG22/25C |

|---|---|---|---|

| Surface Treatment: | Sand Blast, Polishing, Mirror Surface | Hardness HRA: | 82.5 |

| T.R.S: | 2950 | Density: | 13.1-14.0 G/cm3 |

| Diameter D: | 10-100mm | Diameter D: | 2-30mm |

| Length L: | 10-60mm | Power Source: | Electric |

| Engine Type: | Electric | Surface: | Coated |

| Grade Options: | YG6, YG8, YG11, YG12, YG15, YG20, YG20C, YG22C, YG25C, GT55, ML40, ML100, ST7, VA90, C5 | T.R.S Range: | 2500-3100 MPα |

| Hardness Range: | 82.5-87.5 HRA | ||

| Highlight: | Customizable OEM Tungsten Carbide Die,Polished Surface Cold Heading Die,Grade GT40 GT50 GT55 Carbide Nib |

||

Product Description

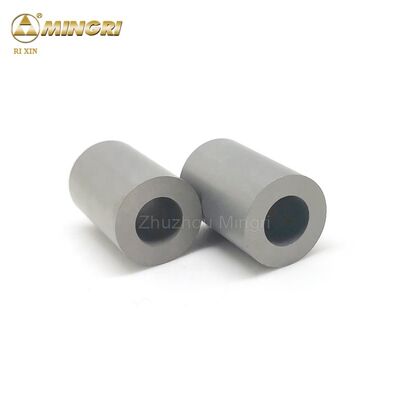

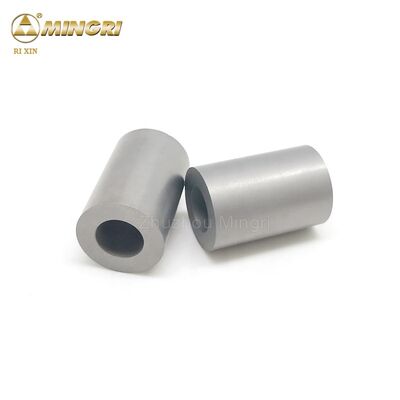

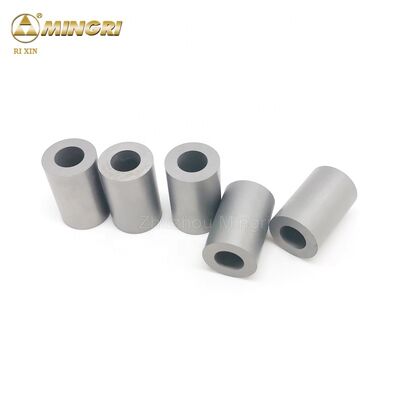

GT40, GT50, GT55 Grade Tungsten Carbide Cold Heading Dies

High-performance tungsten carbide dies and nibs for cold heading applications, designed for steel and stainless steel processing with polished surfaces and customizable OEM specifications.

Product Specifications

| Item | Tungsten carbide die |

|---|---|

| Grade | YG6, YG8, YG11, YG12, YG15, YG20, YG20C, YG22C, YG25C, GT55, ML40, ML100, ST7, VA90, C5 |

| Sizes | Standard or customized |

| Brand | Rixin |

| Country of Origin | Zhuzhou, China |

| Usage | Die casting mould, punch dies, wire drawing die, machine mold, progressive die, extrusion die, press mold, mould parts, trimming die, cold heading die, forging mold, cold forming die |

Tungsten Carbide Grades and Applications

| Grade | Density (g/cm³) | T.R.S (MPa) | Hardness (HRA) | Properties & Applications | Approx Grades in China |

|---|---|---|---|---|---|

| YM15 | 14.0 | 2500 | 87.5 | Suitable for drawing steel tubes and rods under high compression ratio, manufacturing upsetting, punching and forging tools under large stress | YG15 |

| YM20 | 13.5 | 2800 | 85.5 | Suitable for manufacturing punching dies for watch parts, leaf spring of musical instruments, battery jars, small sized steel balls, screws, screw caps | YG20 |

| ML36 | 13.7 | 2800 | 84.5 | Suitable for impact-resistant forging dies, hot-forging dies and finishing rollers | YG18C |

| ML40 | 13.5 | 2850 | 83.5 | Suitable for wear resistant or impact resistant dies | YG20C ZL40.2 |

| ML50 | 13.3 | 2900 | 83.0 | Suitable for nut forming dies and high impact-resistant dies | YG22C ZL40.5 |

| ML60 | 13.1 | 2950 | 82.5 | Suitable for stainless screw dies and semifinishing rollers | YG25C ZL40B |

| ML80 | 13.1 | 3050 | 83.4 | Suitable for screw cap forming dies with high strength (highest impact-resistant forging dies) | YG25C GT55 |

| ML100 | 13.1 | 3100 | 84 | Suitable for screw cap forming dies with high strength (highest impact-resistant forging dies) | GT55 plus |

Standard Dimensions and Custom Sizing

Standard Size Range:

D: 10-100mm

d: 2-30mm

L: 10-60mm

Other sizes available according to customer requirements

D: 10-100mm

d: 2-30mm

L: 10-60mm

Other sizes available according to customer requirements

Packaging and Delivery Information

| Packing | Paper + paper boxes + exported wooden cartons or paper cases. As a manufacturer, we can provide any packaging according to buyer requirements. |

|---|---|

| Shipping | UPS, TNT, EMS, Fedex, DHL, or as requested |

| Delivery | 7-10 days after confirming all details |

Additional Product Range

Company Overview

Production Facilities

Quality Control and Testing

Team and Industry Presence

Contact Information

Want to Know more details about this product