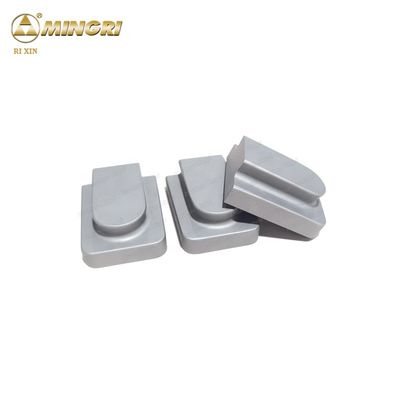

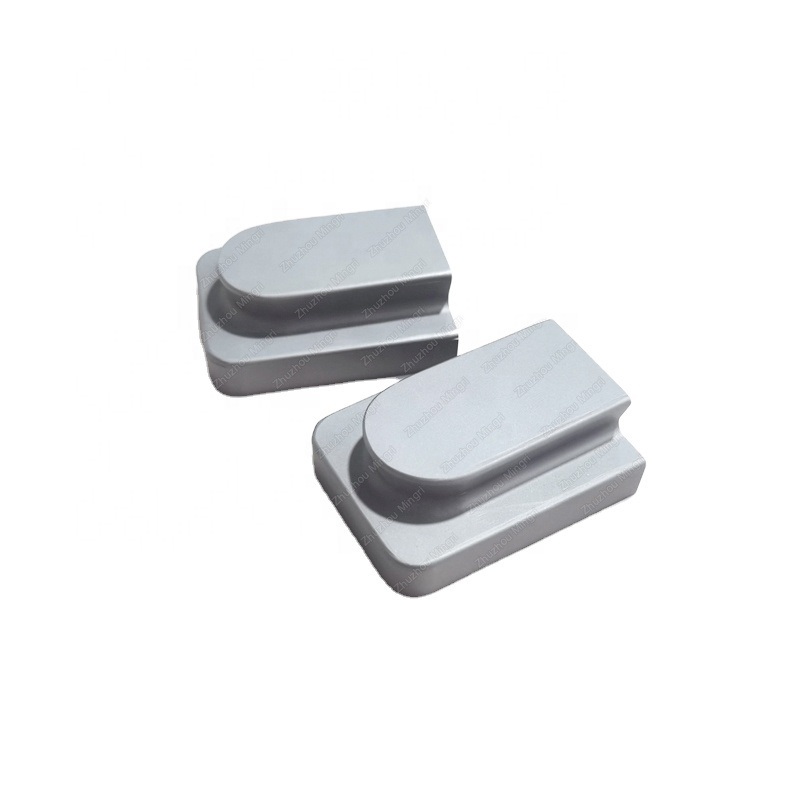

High-Performance YG11C YG15 YG15C Tungsten Carbide Edge Block for HPGR Iron Ore Processing

Product Details:

| Place of Origin: | Hunan, China |

| Brand Name: | Rixin |

| Model Number: | Tungsten carbide stud-3 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | $59 |

|

Detail Information |

|||

| Material: | Tungsten Carbide | Surface Treatment: | Finish Grounded |

|---|---|---|---|

| Surface: | Polished | Grade: | YG11C, YG15, YG15C, YG18, YG20 |

| TRS: | > 3000 N/mm3 | Hardness: | 85-92 HRA |

| Service Life: | 10000 - 30000hrs | Power Source: | Electric |

| Engine Type: | Electric | Size: | Customized |

| Density: | High | Wear Resistance: | High |

| Impact Resistance: | High | Usage: | High Pressure Grinding Roller, Iron Ore, Cement Crushing |

| Performance: | High-Abrasion Resistance | ||

| Highlight: | YG11C Tungsten Carbide Edge Block,YG15 HPGR Edge Block,YG15C Tungsten Carbide Side Block |

||

Product Description

High-Performance HPGR Tungsten Carbide Edge Block for Iron Ore Processing

| Item | Tungsten carbide edge block |

|---|---|

| Grade | YG11C, YG15, YG15C, YG18, YG20 |

| Sizes | Standard or customized |

| Brand | Rixin |

| Country of Origin | Zhuzhou, China |

| Usage | High pressure grinding roller, iron ore, cement crushing |

Tungsten carbide edge blocks are widely used on the rollers of High Pressure Grinding Roll. With excellent properties of high hardness, strength and impact resistance, these components significantly improve the service life and work efficiency of HPGR machines. Compared to traditional hardfacing rollers, tungsten carbide edge blocks offer up to 10 times longer service life.

Grade and Usage Specifications

Available Sizes and Types

Packaging and Delivery

Our Product Range

We specialize in manufacturing various tungsten carbide profiles and dies, cutting tools, mining tools, wear parts, and customized tool parts with exceptional performance for industrial applications.

Manufacturing Capabilities

Our facility includes powder mixing, pressing, sintering, finishing, surface treatment, and mold design workshops, along with physical and chemical testing laboratories. With hundreds of modern equipment, we maintain a monthly production capacity of 50 tons while ensuring excellent quality standards.

Quality Assurance

All products undergo strict ultrasonic inspection before shipment to ensure they are free from defects such as pores. Our tungsten carbide components feature high density, superior wear resistance, and excellent impact resistance, resulting in extended service life.

Our Team and Industry Presence

Contact Information

Want to Know more details about this product