High Hardness and Wear-Resistance Tungsten Carbide Water Jet Nozzle Manufacturer Supply

Product Details:

| Place of Origin: | China |

| Brand Name: | Rixin |

| Certification: | ISO 9001:2008 |

| Model Number: | YG8 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 5pcs |

|---|---|

| Packaging Details: | Cartons |

| Delivery Time: | 7-15 days |

| Supply Ability: | 50+tons+per month |

|

Detail Information |

|||

| Product Name: | Carbide Waterjet Nozzle | Material: | 100% Pure Raw Material |

|---|---|---|---|

| Application: | For Metal Cutting | Grade: | 99% Pure Tungsten |

| Surface Finish: | Polished | Pacakge: | Standard Cartons |

| Usage: | Decoration Industry | Key Words: | Carbide Waterjet Nozzle |

| Highlight: | Tungsten Carbide Water Jet Nozzle Manufacturer,Wear-Resistance Water Jet Nozzle,High Hardness Water Jet Nozzle |

||

Product Description

High Hardness and Wear-Resistance Tungsten Carbide Water Jet Nozzle Manufacturer Supply

Feature of carbide waterjet nozzle

Waterjet, that is, water as a knife, the real name of high-pressure water jet cutting technology, this technology originated in the United States. It is favored for its cold cutting without changing the physicochemical properties of the material. After the continuous improvement of the technology, the grinding of garnet sand, silicon carbide and other abrasives in the high-pressure water assisted cutting, greatly improving the cutting speed and cutting thickness of the waterjet. Waterjet has been widely used in ceramics, stone, glass, metal, composite materials and many other industries. Currently in China, the maximum pressure of waterjet has been 420MPa. Some technologically advanced companies have perfected 3-axis and 4-axis waterjets, and 5-axis waterjets are also maturing.

Material: Special tungsten carbide, which made of pure WC powder with particle size 0.15um, sintered under 2000 degree and 35-65 MPacemented carbide

Hardness: >HRA 97.

Strength: 1000 MPa

Life time: 100-200 hours

Water Press: 250 MPa- 400MPa

Water Velocity: 800 m/s-1000 m/s.

Application: cutting hard metal.

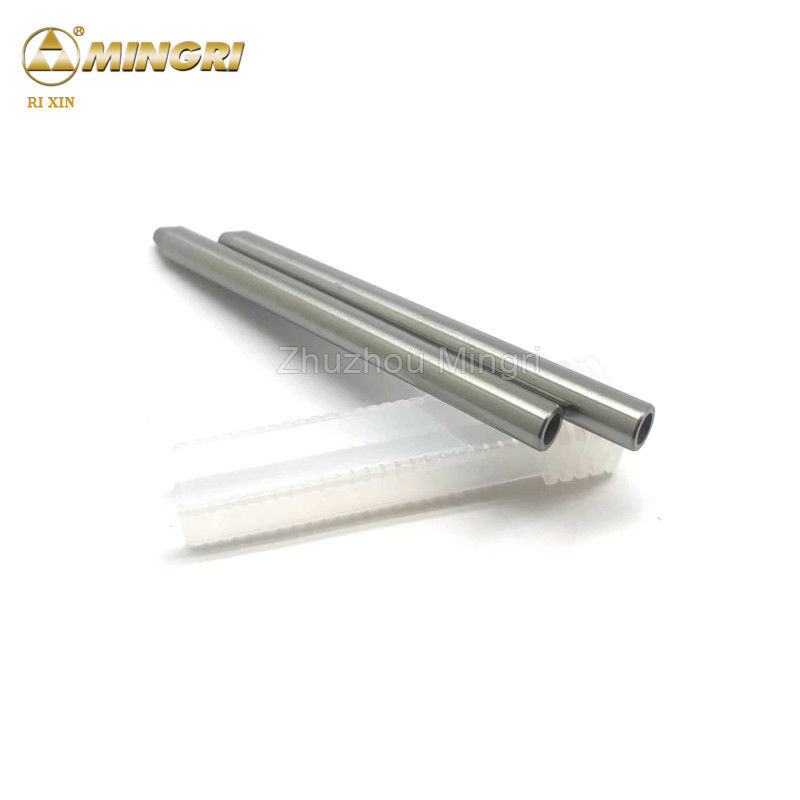

Description of carbide waterjet nozzle

![]()

| Item No | D (mm) | d (mm) | L (mm) |

| MR6030 | 6 | 0.76 | 76.2 |

| MR6040 | 6 | 1.02 | 76.2 |

| MR020 | 6.35 | 0.5 | 76.2 |

| MR030 | 6.35 | 0.76 | 76.2 |

| MR040 | 6.35 | 1.02 | 76.2 |

| MR7030 | 7.14 | 0.76 | 76.2 |

| MR7040 | 7.14 | 1.02 | 76.2 |

| MR76030 | 7.6 | 0.76 | 76.2 |

| MR76040 | 7.6 | 1.02 | 76.2 |

| MR945030 | 9.45 | 0.76 | 76.2 |

| MR945040 | 9.45 | 1.02 | 76.2 |

2. Competitive price with prompt delivery

3. Excellent service with many professional sales and engineers

4. OEM manufacturing supplied ( Including client's own brand )

5. Suitable packing according to customer's requirements

1. Refers to the high pressure abrasive water jet machine tool jet exit is used as the abrasive nozzle is mixed withwater.

2. The use of ultra-high pressure technology can turn ordinary tap water pressure to 250 ~ 400 mpa pressure, and then through the inner hole diameter to 0.15 ~ 0.35 mm ruby nozzle spray forming speed is about 800 ~1000 m/s high speed jet.

3. The nozzle and sand tube not to cause the premature wear of pipe, in order to prolong the service life of the sand tube, before use, first with sand tube with water, ensure that the water in the center position.Rotary sand tube will increase to 120 degree of wear and tear.Should pay attention to the following three questions:

(1) the gem (diamond) have tube to the nozzle from the sand.

(2) check whether there is new gems (diamond) nozzle hole.

(3) the room appear mixed sand abrasion.

![]()