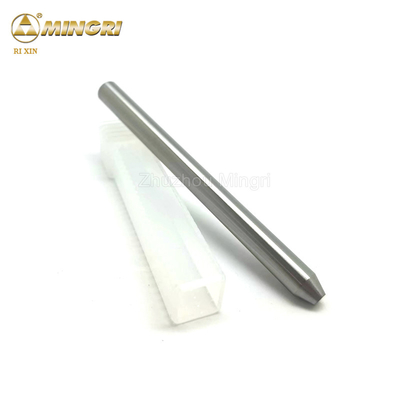

Tungsten Cemented Carbide Waterjet Cutting Nozzle Cutting Rubber

Product Details:

| Place of Origin: | China |

| Brand Name: | Rixin |

| Certification: | ISO 9001:2008 |

| Model Number: | YG8 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 5pcs |

|---|---|

| Packaging Details: | Cartons |

| Delivery Time: | 7-15 days |

| Payment Terms: | L/C,T/T |

| Supply Ability: | 50+tons+per month |

|

Detail Information |

|||

| Product Name: | Carbide Waterjet Nozzle | Material: | 100% Tungsten |

|---|---|---|---|

| Application: | For Rubber Cutting | Grade: | 100% Tungsten |

| Surface Finish: | Polished | Pacakge: | Standard Cartons |

| Usage: | Decoration Industry | Key Words: | Carbide Waterjet Nozzle |

| Highlight: | Cemented Carbide Waterjet Cutting Nozzle,Waterjet Cutting Nozzle Cutting Rubber,Tungsten Carbide Waterjet Cutting Nozzle |

||

Product Description

High Quality For Cutting Rubber Tungsten Cemented Carbide Waterjet Cutting Nozzle

Description of carbide waterjet nozzle

1, Standard water jet nozzle

effectively extend the working life of the waterjet sand mixing pipe and successfully break through 150 hour working time of the traditional waterjet. It is currently the most widely used model in the world.

2, RIXIN enhanced nozzle

on the basis of type, further increase of strong performance, increase its density and hardness, and at the same time make its wear resistance to a higher leverl

3, RIXIN economy nozzle

using the same material and different production process , the production cost is greatly reduced, and the performance is well controlled , the unique golden yellow exterior coating is a good anti-counterfeiting technology.

4, RIXIN customized nozzle

we can produce according to customer requirement such as special shape or grinding or cost.

|

Product name |

carbide waterjet nozzle |

|

Material |

100% virgin tungsten |

|

Color |

grey |

| Standard |

ISO 9001:2008 |

| Dimensions(mm) |

D(6~ 9.45) x d(0.5 ~ 1.02) x L 76.2 |

Feature of carbide waterjet nozzle

1. High hard resistance

2. High corrosion resistance

3. Pressured resistance

4. Wear resistance

5. High bending strength

1. Refers to the high pressure abrasive water jet machine tool jet exit is used as the abrasive nozzle is mixed with water.Because of its internal Jet conditions are harsh, the abrasive wear was accelerated after the water inside the tube is very large, so need to use very wear resisting material.Materials for manufacturing, carbide tube structure is very simple,basically consists of two sections, and a columnar entrance and cone exports.Due to the different uses its size slightly difference.

2. The use of ultra-high pressure technology can turn ordinary tap water pressure to 250 ~ 400 mpa pressure, and then through the inner hole diameter to 0.76 ~ 1.02 mm ruby nozzle spray forming speed is about 800 ~1000 m/s high speed jet, commonly known as it is Water arrows, if arrow has the very high energy, can be used to cut almost all hard and soft materials.Adjust the water jet pressure and flow, can use its various cleaning objects, such as glue, paint, rust removal, etc.

3. The carbide water jet nozzle and tube not to cause the premature wear of pipe, in order to prolong the service life of the carbide water jet nozzle, before use, first with tube with water, ensure that the water in the center position.Should pay attention to the following three questions:

(1) ensure that the water in the center position.

(2) check whether inner hole of tube is straight.

(3) check if water mixed with other hard something.

If there is no on the jet, jet will directly impact the tube wall, led to the decrease of the cutting speed, at the same time, carbide water jet nozzle tube service life will be dramatically reduced.Normal carbide tube wear an from inlet to outlet of centripetal and continuous wave wear trace.

![]()