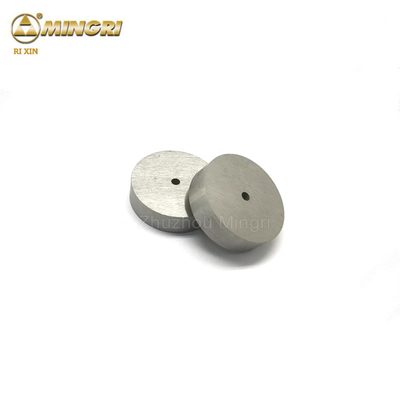

Tungsten Carbide Puching Die For Punching Mould Tool Parts

Product Details:

| Place of Origin: | China |

| Brand Name: | Rixin |

| Certification: | CE ROHS UL |

| Model Number: | Varies |

Payment & Shipping Terms:

| Minimum Order Quantity: | 5KG |

|---|---|

| Packaging Details: | cartons |

| Delivery Time: | 5-15 days |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 50+Tons+per month |

|

Detail Information |

|||

| Features: | Good Wear Resistance | Product Name: | Carbide Punching Die |

|---|---|---|---|

| Material: | Tungsten Carbide | Grade: | GT55/ML40/ML100 |

| Application: | Punching Tools | Finish: | Blank/polish |

| Keyword: | Carbide Punching Die | ||

| Highlight: | Tungsten Carbide Puching Die,GT55 Tungsten Carbide Puching Die,Punching Tools Tungsten Carbide Die |

||

Product Description

For Punching Mould Tool Parts Professional Factory Made Tungsten Carbide Puching Die

Specifications of carbide cold heading die

Our carbide die nibs and moulds have good impact resistance, fatigue resistance and wear resistance.

You are encouraged to use our professional carbide grades for cold heading and punching die nibs, powder

metallurgical compacting dies and other industries. For stable performance and high cost effectiveness,

they have been proved to be ideal in making nonferrous metal, ferrous metals and their alloys.

| Mingri Grade | Density | Hardness | TRS(Mpa) | Application | Grade in China |

| YM13 | 13.5 | 83.5 | 3000 | Good wear resistance and bending strength. It is often preferred by nut forming dies and high impact-resistant dies | YG13 |

| YM11 | 14.4 | 88.5 | 2420 | Forming or stamping dies for metal powders and nonmetal powders | YG11 |

| YM15 | 14.0 | 87.0 | 3000 | It is suitable for drawing steel tubes and rods under high compression ratio, manufacturing upsetting, punching and stampling tools under large stress. | YG15 |

| YM20 | 13.5 | 85.5 | 2800 | It is suitable for manufacturing punching dies for watch parts, leaf spring of musical instruments, battery jars, small sized steel balls, screws, screw caps,etc. | YG20 |

| ML32 | 13.9 | 85 | 2750 | It is suitable for impact- resistant forging dies | YG16C |

| ML35 | 13.7 | 84 | 2800 | It is suitable for impact- resistant forging dies, hot- forging dies and finishing rollers. | YG18C |

| ML40 | 13.5 | 83.0 | 2850 | It is suitable for wear resistant or impact resistant dies. | YG20C ZL40.2 |

| ML50 | 13.3 | 82.0 | 2900 | It is suitable for nut forming dies and high impact-resistant dies. | YG22C ZL40B |

| ML60 | 13.1 | 81.5 | 2950 | It is suitable for stainless screw dies and semifinishing rollers. | YG25C ZL40B |

| ML80 | 13.1 | 83.0 | 3200 | It is suitable for screw cap forming dies with high strength(highest impact- resistant forging dies. | GT5 |

Our guarantee:

100% raw material | ISO9004:2008 certificate, ISO 14001:2004 |

| sintered in HIP furnace | fully adopted in advance technology and equipment |

| size standard as per your requirements | professional manufacture for tungsten carbide items with 20 years experience |

| professional suggestion on products | fully adopted in advance technology and equipment |

| feedback within 24 hours | quality control system and strict inspection |

Delivery of carbide cold heading die

A.Regular packing:Paper box inside and carton outside or other suitable packing

B.Delivery time:15-25 days once confirm the order

C.Way of shipping:Express/ air/sea/land

Company Information

We provide the best quality for you only! Our company, through more than twenty years development and expansion,

has made a great leap forward in management level and the quality of products, enjoying a rather high reputation in the

carbide industry.

The company-made carbide items have the following advantages: various sizes, complete grades,

excellent performance, stable good quality. Our products can well meet the different requirement of all customers.

Our carbide products occupy important market share and are exported well to the areas of Southern Asia, Europe

and America.

![]()