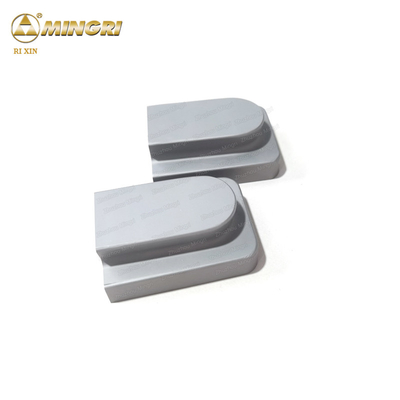

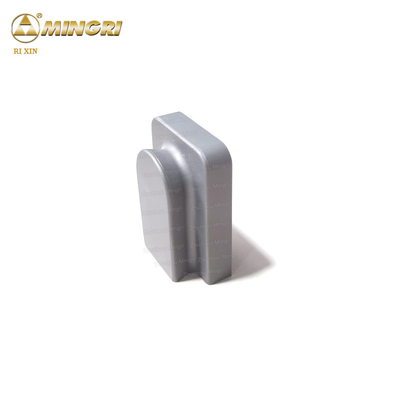

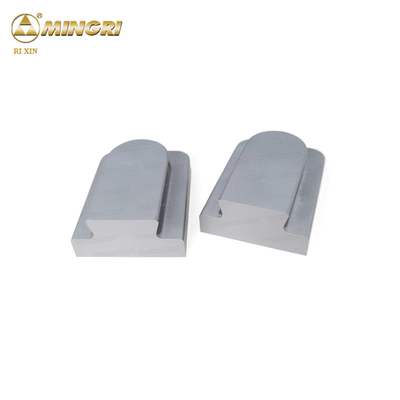

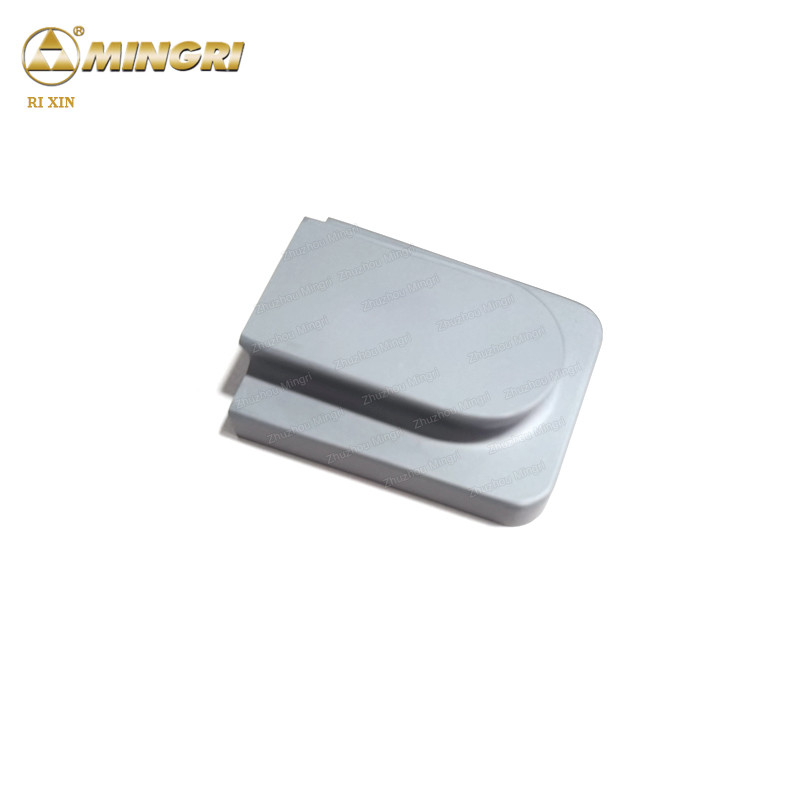

HPGR Wear Resistance Block Tungsten Cemented Carbide Edge Block

Product Details:

| Place of Origin: | China |

| Brand Name: | Rixin |

| Certification: | CE ROHS UL ISO |

| Model Number: | RX-11,RX-15,RX650,RX20 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 5KG |

|---|---|

| Price: | USD + 65~32 + KG |

| Packaging Details: | Cartons |

| Delivery Time: | 5-15 days |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 50+tons+per month |

|

Detail Information |

|||

| Keyword: | Carbide Edge Block | Material: | 100% Virgin Gungsten Carbide |

|---|---|---|---|

| Usage: | HPGR Studs | Place Of Origin: | Hunan, China |

| Product Name: | Carbide Edge Block | Surface: | Blank / Finished |

| Tolerance: | As Per Your Requirment | ||

| Highlight: | HPGR Wear Resistance Block,Tungsten Cemented Carbide Edge Block,HPGR Cemented Carbide Edge Block |

||

Product Description

Rixin brand good quality HPGR wear-resistance block tungsten cemented carbide edge block

Description of carbide edge block

1. Round edges, protect the carbide edge block being damaged during production, transportation, installment and using.

2. HIP sintering ensure good compactness and high toughness for the products.

3. Special technology to eliminate the surface stress after surface grinding, and increase the surface hardness at the same time.

4. Grease used on surface of the products to avoid oxidization.

Grades below are exclusive grade we developed for rolling machine. Good wear resistance and high strength are suitable for metal smashing with high working efficiency. Lifetime of carbide edge block over 8000-10000 hrs.

Dimensions can be done by client's drawing.

| Grades | Density(g/cm3) | Hardness(HRA) | T.R.S≥N/mm2 |

| RX-11 | 14.4 | 87 | 2700 |

| YG15 | 14 | 87 | 3000 |

| YG15C | 14 | 87 | 2700 |

| RX20 | 13.5 | 85.5 | 3200 |

Advantages of cemented carbide studs

1. continuous production of buttons over 20 years

2. total production quantity of buttons up to 800 tons

3. widely exported to Europe,America,Austrialia,Brazil,India,Russia etc

4. round edges,protect the studs being damaged during production,transpotation,installment and using

5. Hip sintering ensure good compactness and high toughness for the products

6. grease used on surface of the products to avoid oxidization

7. hemishperical top,protect the studs from being destroyed by stress concentration

Production process of cemented carbide studs

1, Soon after the order is confirmed, tungsten carbide studs products will start to prepare the RTP powder as per customer’s requirement with our wet-grinding machine

2, Before mass production, we need to do a trial pressing and sintering using every mould, and we check the appearances and the sizes of tungsten carbide studs samples with micrometer, projectors etc. to ensure that the requirements of the drawings can be met before batch production

3, Bulk production ,press the raw materials to shape blanks,and all tungsten carbide studs blanks must be passed by semi finished inspection,

company information

2001.05 factory of Zhuzhou Mingri Cemented Carbide Company was established in Zhuzhou

2003.04 the company renamed Zhuzhou Mingri Cemented Carbide Co., Ltd

2006.06 the company moved into SME Promotion Park in Tianyuan District, Zhuzhou

2009.03 Zhuzhou Mingri moved to Liyu Industrial Area, where our newly built factory is located

2010.01 the road built with our company's sponsorship is formally named" Mingri Road",which is a conspicusous landmark in Zhuzhou

2010.05 Zhuzhou Mingri was invited to take part in World Expo Shanghai

2010.12 our first invention patent was formally granted

2010.12 our brand "RIXIN" was rated as famous trademark of Hunan province

2011.05 10th Anniversary celebration

2011.06 Zhuzhou Mingri was honored as high-tech enterprise in Hunan Province

2012.09 our own brand RIXIN was successfully registered

2013.08 our brand RIXIN was rated as internationally well-known brand

2013.12 Zhuzhou Mingri passed the authentication of ISO9001:14001 successfully