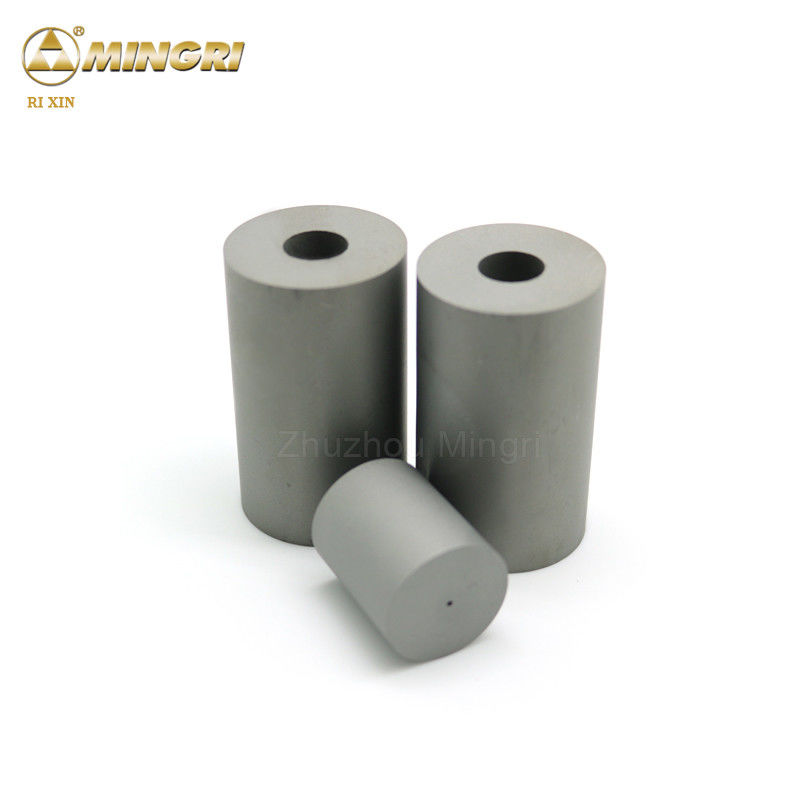

Bushing Tungsten Carbide Die Nibs G55 Hard Alloy Metal For Fastener Industry

Product Details:

| Place of Origin: | ZHUZHOU,HUNAN,CHINA |

| Brand Name: | RI XIN |

| Certification: | ISO9001:2008 ISO14001:2004 |

| Model Number: | rixin-1 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 KG |

|---|---|

| Price: | 53$/kg |

| Packaging Details: | First in small cartons filled with cotton, then in bigger cartons. |

| Delivery Time: | 7-20 business days |

| Payment Terms: | D/A, L/C, D/P, T/T, Western Union |

| Supply Ability: | 50 Tons per month |

|

Detail Information |

|||

| Grades: | YG15,YG18,YG20,YG22,YG25 | Material: | Tungsten ,Cobalt,100% Virgin Raw Material |

|---|---|---|---|

| Application: | Cold Heading Die,Cold Forging Die,Nut Forming Dies,Flow Restrictor Etc. | Surface Treatment: | Grinding,Sand-blasting,Polishing |

| Density: | 13.1 | HRA: | 83.8 |

| Strength: | 3200 | Key Word: | Cemented Carbide Nib Pellets |

| Color: | Gray | Company Type: | Manfacturer |

| Highlight: | tungsten carbide tools,tungsten carbide tooling,Bushing Tungsten Carbide Die Nibs |

||

Product Description

Cemented Tungsten Carbide Bushing Die Nibs G55 Hard Alloy Metal For Fastener Industry

Applications :

Tungsten carbide pellets dies are widely used in cold heading,forging,stamping and punching dies for maufacturing nuts, screw caps, bolts, cans and many other products.

Our Advantages :

1. Strong Mould R&D team. We support product customization as per specific requirements, ensure high working efficiency with good product quality.

2. Successful cooperation case: We cooperate with clients in domestic and abroad, and get good feedback from them.

3. Strong R&D team. Professional engineers serve for clients, recommend products and grades as per your applications. We also offer after-sale service.

4. ISO 9001:2015 Quality Control System,

5. 100% raw material for production.6. Hip sintered, reliable hardness, durable wear resistance

6. Various sizes, carbide grade and full types available

7. Competitive price with on-time delivery

8. Customized product as per drawing and small order accepted,professional and in-time technical support

Grade:

| Grade | Density g/cm3 |

T.R.S MPα |

Hardness HRA |

Properties & Applications | Approx Grades in China |

| A | 13.5 | 3000 | 83.5 | Good wear resistance and bending strength. It is often preferrd by nut forming dies and high impact-resistant dies. | — |

| YM11 | 14.4 | 2420 | 88.5 | Forming or stamping dies for metal powders and non-metal powders. | YG11 |

| YM15 | 14.0 | 2500 | 87.5 | It is suitable for drawing steel tubes and rods under high compression ratio, manufactuing upsetting, punching and forging tools under large stress. | YG15 |

| YM20 | 13.5 | 2800 | 85.5 | It is suitable for manufacturing punching dies for watch parts, leaf spring of musical instruments, battery jars, small sized steel balls, screws, screw caps, etc. | YG20 |

| ML32 | 13.9 | 2750 | 85.5 | It is suitable for impact-resistantance forging dies. | YG16C |

| ML36 | 13.7 | 2800 | 84.5 | It is suitable for impact-resistant forging dies, hot-forging dies and finishing rollers. | YG18C |

| ML40 | 13.5 | 2850 | 83.5 | It is suitable for wear resistant or impact resistant dies. | YG20C ZL40.2 |

| ML50 | 13.3 | 2900 | 83.0 | It is suitable for nut forming dies and high impact-resistantance dies. | YG22C ZL40.5 |

| ML60 | 13.1 | 2950 | 82.5 | It is suitable for stainless screw dies and semifinishing rollers. | YG25C ZL40B |

| ML100 | 13.1 | 3050 | 83.4 | It is suitable for screw cap forming dies with high strength ( highest impact-resistant forging dies). | YG25C GT55 |

| Other grades of cemented carbide blanks for cold-forging dies may be offered by customers' requirements | |||||

Specifications:

Including but not limited to the following types.

![]()

![]()

FAQ

1.Q :What is your main product ?

A:Tungsten carbide mining tool,cutting tools ,wear resistance parts and all kinds of cutting knives etc

2.Q:what's your price ?

A: please offer us your details or draing about the dimension and tolerance,application,we can recommend you the right grade,then we will offer you a clear quotation

3.Q:Are your products high quality ?

A:Yes. All products will be tested before bulk production, and we will check the physical properties, shape and tolerance for ensuring qualified products before shipping.

4.Q:Are you factory or trading ?

A:we are manufacturer in zhuzhou city ,more than 17 years old

5.Q: How to place an order?

A:1. Fill your Order List in our online Inquiry System.

(Also you can directly contact our salesperson by E-mail / Skype / Whats App)

2. We will make a feedback to you ASAP after receive your order list

Feel free to contact me if any needs:

Whatsapp/wechat/phone:008618593402651

Facebook:Xiao Aimee

zhuzhou mingri cemented carbide co. ltd

Email:mr009@mrcarbide.com