A40 A50 Tungsten Brazing Carbide Tips

Product Details:

| Place of Origin: | ZhuZhou China |

| Brand Name: | none |

| Certification: | ISO9001:2008 ISO14001:2004 |

| Model Number: | many |

Payment & Shipping Terms:

| Minimum Order Quantity: | 30KG |

|---|---|

| Packaging Details: | Packed in carton firstly,and then reinforced with wooden case for outer packing |

| Delivery Time: | 15 working days after received your payment |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 30 ton/ per month |

|

Detail Information |

|||

| Product Name: | Welding Blades | Application: | Cutting Tools |

|---|---|---|---|

| Size: | Standard | Grade: | YT5,YG8..... |

| Highlight: | brazing carbide tips,brazed carbide tools,A50 Tungsten Brazing Carbide Tips |

||

Product Description

A40 A50 Tungsten Carbide Inserts Cutting tools ISO14001 2004

Specifications:

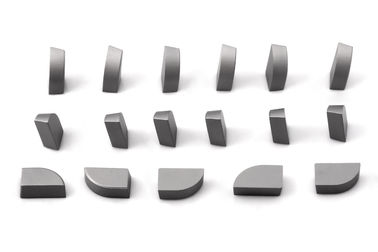

Type A

![]()

|

Type |

Dimensions (mm) |

||||

|

|

L |

t |

S |

r |

a° |

|

A5 |

5 |

3 |

2 |

2 |

- |

|

A6 |

6 |

4 |

2.5 |

2.5 |

- |

|

A8 |

8 |

5 |

3 |

3 |

- |

|

A10 |

10 |

6 |

4 |

4 |

18 |

|

A12 |

12 |

8 |

5 |

5 |

18 |

|

A16 |

16 |

10 |

6 |

6 |

18 |

|

A20 |

20 |

12 |

7 |

7 |

18 |

|

A25 |

25 |

14 |

8 |

8 |

18 |

|

A32 |

32 |

18 |

10 |

10 |

18 |

|

A40 |

40 |

22 |

12 |

12 |

18 |

|

A50 |

50 |

25 |

14 |

14 |

18 |

Type B

![]()

|

Type |

Dimensions (mm) |

||||

|

|

L |

t |

S |

r |

a° |

|

B5 |

5 |

3 |

2 |

2 |

- |

|

B6 |

6 |

4 |

2.5 |

2.5 |

- |

|

B8 |

8 |

5 |

3 |

3 |

- |

|

B10 |

10 |

6 |

4 |

4 |

18 |

|

B12 |

12 |

8 |

5 |

5 |

18 |

|

B16 |

16 |

10 |

6 |

6 |

18 |

|

B20 |

20 |

12 |

7 |

7 |

18 |

|

B25 |

25 |

14 |

8 |

8 |

18 |

|

B32 |

32 |

18 |

10 |

10 |

18 |

|

B40 |

40 |

22 |

12 |

12 |

18 |

|

B50 |

50 |

25 |

14 |

14 |

18 |

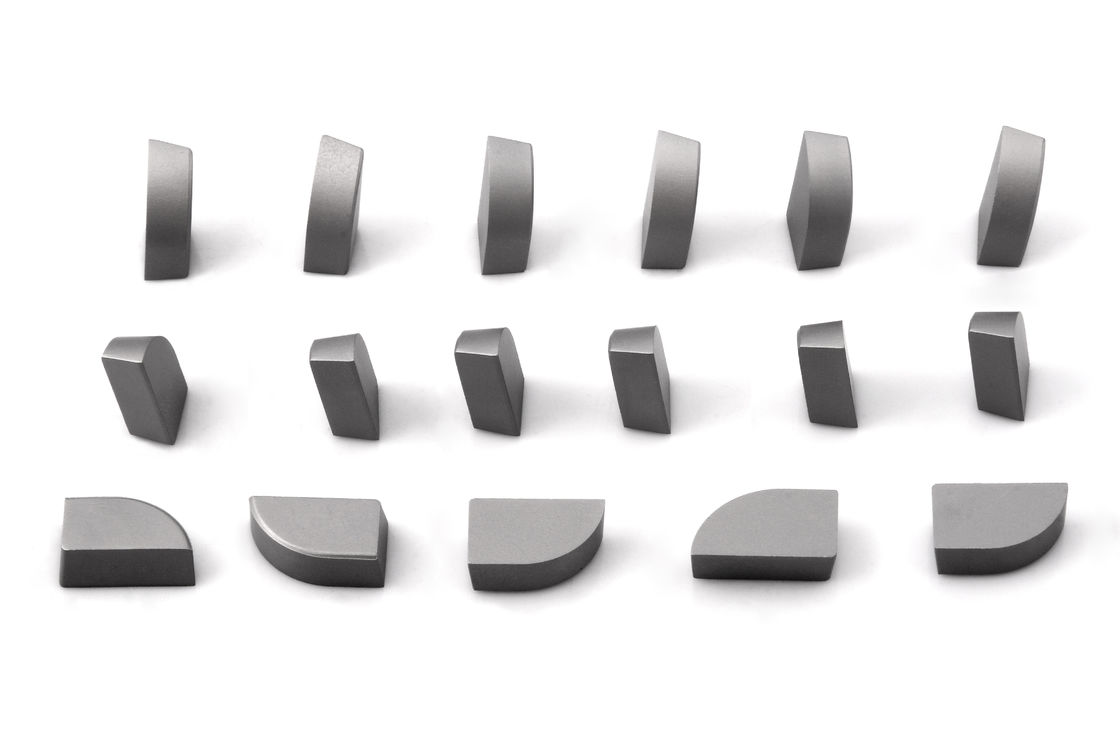

Type C

![]()

|

Type |

Dimensions (mm) |

|||

|

|

L |

t |

S |

a° |

|

C5 |

5 |

3 |

2 |

- |

|

C6 |

6 |

4 |

2.5 |

- |

|

C8 |

8 |

5 |

3 |

- |

|

C10 |

10 |

6 |

4 |

18 |

|

C12 |

12 |

8 |

5 |

18 |

|

C16 |

16 |

10 |

6 |

18 |

|

C20 |

20 |

12 |

7 |

18 |

|

C25 |

25 |

14 |

8 |

18 |

|

C32 |

32 |

18 |

10 |

18 |

|

C40 |

40 |

22 |

12 |

18 |

|

C50 |

50 |

25 |

14 |

18 |

Type D

![]()

|

Type |

Dimensions (mm) |

||

|

|

L |

t |

S |

|

D3 |

3.5 |

8 |

3 |

|

D4 |

4.5 |

10 |

4 |

|

D5 |

5.5 |

12 |

5 |

|

D6 |

6.5 |

14 |

6 |

|

D8 |

8.5 |

16 |

8 |

|

D10 |

10.5 |

18 |

10 |

|

D12 |

12.5 |

20 |

12 |

Type E

![]()

|

Type |

Dimensions (mm) |

|||

|

|

L |

t |

S |

a° |

|

E4 |

4 |

10 |

2.5 |

- |

|

E5 |

5 |

12 |

3 |

- |

|

E6 |

6 |

14 |

3.5 |

- |

|

E8 |

8 |

16 |

4 |

9 |

|

E10 |

10 |

18 |

5 |

9 |

|

E12 |

12 |

20 |

6 |

9 |

|

E16 |

16 |

22 |

7 |

9 |

|

E20 |

20 |

25 |

8 |

9 |

|

E25 |

25 |

28 |

9 |

9 |

|

E32 |

32 |

32 |

10 |

9 |

Description:

1,Used for steel, stainless steel, cast steel and cast iron cutting and processing.

2, Good toughness

3 ,Superior wear resistance & high strength

4 ,A comprehensive range of types with molds

5 ,Short deliver period,with some types always in stock

6,Full-automatic press machine,which brings stable quality and high efficiency

Applications:

| Grade | ISO Code | Density | Hardness | T.R.S | Applications recommended |

| g/cm3 | HRA | MPa | |||

| YM3 | K05 | 15.1 | 92 | 1400 | Suitable for finishing of cast iron and nonferrous metal. |

| YM6X | K10 | 14.95 | 91.5 | 1800 | The finishing & semi-finishing of cast iron and nonferrous metals and also for the machining of manganese steel and hardening steel. |

| YM6 | K15 | 14.95 | 90.5 | 1900 | Suitable for the roughing of cast iron and light alloys and also for the milling of cast iron and low-alloy steel. |

| YM8 | K20 | 14.8 | 89.5 | 2200 | |

| YW1 | M10 | 13.1 | 91.6 | 1600 | Suitable for finishing and semi-finishing of stainless steel and conventional alloy steel. |

| YW2 | M20 | 13 | 90.6 | 1800 | The grade can be used for the semi-finishing of stainless steel and low-alloy steel and it is mainly used for the machining of railway wheel hubs. |

| YT15 | P10 | 11.4 | 91.5 | 1600 | Suitable for the finishing and semi-finishing for steel and cast steel with a moderate feed rate and rather high cutting speed. |

| YT14 | P20 | 11.6 | 90.8 | 1700 | Suitable for the finishing and semi-finishing of steel and cast steel. |

| YT5 | P30 | 12.9 | 90.5 | 2200 | Suitable for the heavy duty rough turning of and cast steel with a big feed rate at a medium and low speed under unfavorable working conditions. |

Competitive Advantage:

1. Focusing on manufacturing tungsten carbide products over 13 years.

2. Specialist manufacturer equipped with advanced processing machines and over160 technicians

3. Over 50 tons/month productivity to assure sustainable supply of products

4. Owing mould workshop to design & produce moulds for nonstandard products, and with mould stocks over 10 thousand sets for different products.

5. Full ability to accept OEM & ODM orders

6. Stringent quality control and quality consistency.

7. Professional mechanical & chemical inspecting labs to control the quality of raw material and

inspect physical & mechanical properties of finished products.