Sharp Cutting Edge Tungsten Carbide Disc Slitter

Product Details:

| Place of Origin: | China |

| Brand Name: | Rixin |

| Certification: | CE ROHS UL ISO |

| Model Number: | 300mm*160mm*3.3mm 12 holes |

Payment & Shipping Terms:

| Minimum Order Quantity: | 5 piece |

|---|---|

| Price: | USD+240+per piece |

| Packaging Details: | Cartons |

| Delivery Time: | 15-20 days |

| Payment Terms: | T/T |

| Supply Ability: | 50+tons+per month |

|

Detail Information |

|||

| Keyword: | Carbide Disc Slitter | Material: | 100% Raw Material |

|---|---|---|---|

| Usage: | Cut Wet Silicate Board | Application: | Cutting Machine |

| Product Name: | Carbide Disc Slitter | Surface: | Two Sides Polished |

| Shape: | Round With 12 Holes | ||

| Highlight: | tungsten carbide blade,carbide rotary cutter,Tungsten Carbide Disc Slitter |

||

Product Description

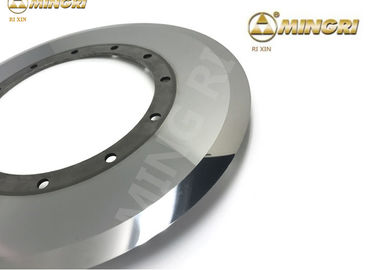

sharp cutting edge tungsten carbide disc slitter with 12 holes for silicate board cutting

Product description of carbide disc slitter

1, Product name : carbide disc slitter for wet silicate board cutting

2, The cutting edge is angle 12 degree, two sides polished.

3, Size: OD 300mm × ID 160mm × T 3.3mm

4, Hole: 12 holes with D 8MM

5, Angle cutting : 12 degree or 18 degree, single angle cutting or double

6, Surface treatment: parallelism 0.4, flatness 0.2

7, Raw material: 100% virgin tungsten carbide

| Grade | Density | T.R.S | Hardness | characteristics and Application |

| g/cm3 | ≥ N/mm2 | HRA | ||

| MR09 | 14.75 | 2800 | 90 | prefessionally cut silicate board |

![]()

Production flow of carbide disc slitter

1. About raw materials and powder:

Soon after the order is confirmed, our production will start to prepare the RTP powder as per customer’s requirement with our wet-grinding machine.

2. About pressing:

Before mass production, we need to do a trial pressing and sintering using every mould, and we check the appearances and the sizes of the samples with micrometer, projectors etc. to ensure that the requirements of the drawings can be met before batch production;

3. About Furnace:

12 sets of vacuum sintering furnace and 1set of HIP in the factory ensure the best quality and production capacity.

4. About cleaning/tumbling :

1).cleaning/tumbling is to make the products look more beautiful.

2).The goods can be ground according to customers’ requirement

5 About laboratory:

We sample each batch RTP into pressing and sintering, only when certificated by the laboratory, the RTP can be put into mass production.

Company information

230 workers, 8000 m2 non-dust workshop, 18 years experience , 10000 sets mould, 5 workshop included grinding powder workshop, pressing workshop, sintering workshop, processing workshop, mould production workshop, production capacity 50tons/month, well-known brand ”Ri Xin” has registered in Europe for 6 years , ISO, CE&FDA certificated.

Our main products cover cold heading dies, wire drawing dies, strips and plates, saw tips, brazed tips, disc cutters, round rods, rock drilling bits and buttons, milling tools, also we can make all kinds of customized proposal to meet customers’ requirement.

![]()

Customer feedback

![]()