Tungsten Carbide Copper Blasting Crushed Grit TC Wear Resisting Welding Tips

Product Details:

| Place of Origin: | China,zhuzhou |

| Brand Name: | rixin |

| Certification: | CE,ISO |

| Model Number: | wear resistance parts |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1kg |

|---|---|

| Price: | customized |

| Packaging Details: | As per customer's requirements |

| Delivery Time: | 12-30 business days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 50tons/month |

|

Detail Information |

|||

| Material: | Tungsten +Cobalt | Color: | Black Or Silver |

|---|---|---|---|

| Application: | For Had Facing | Abrasive Grain Size: | 5-80 Mesh |

| Use: | Wear-resisting Welding Tips | ||

| Highlight: | cemented carbide tips,tungsten carbide tool tips |

||

Product Description

Wear resistance Tungsten Carbide Grit for hard facing material

Description

This tungsten carbide grit also called tungsten grints, carbide grits, it is used to welding or solder onto a steel body, to increase the wear resistance properties. For example, if a steel cutter can cut 24 hours without grits, it will cut 240 hours after with the tungsten carbide grits.

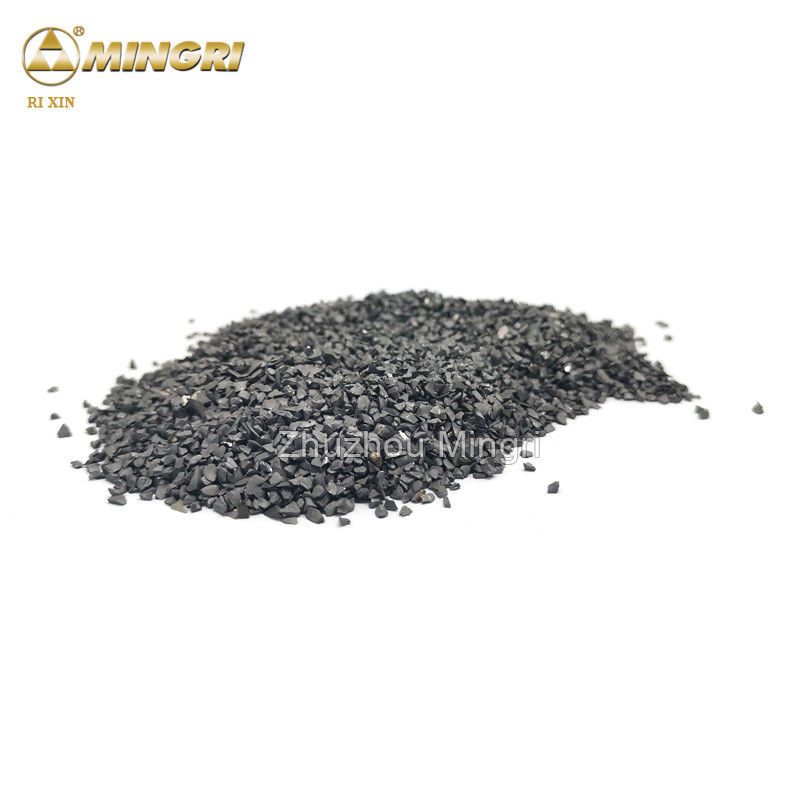

Size of Tungsten crushed carbide grits

| TC Grits | 1-12 mesh |

| Crushed grits | 12-20 mesh |

| 20-30 mesh | |

| 30-40 mesh | |

| 40-60 mesh |

The normal size (mesh) of tungsten carbide grits

1-12mesh / 12-20 mesh/ 20-30 mesh/ 30-40 mesh/ 40-60 mesh/ 60-80 mesh

1-2 mm/ 3.2-4.8 mm/ 4.8-6.4 mm/ 12 mm etc.

Application

The tungsten carbide grit is suitable for hard facing material.

1 mesh to 12 mesh: used for wear-resistant electrode and mace electrode;

10 mesh to 60 mesh: used for saw blade or play a role of wear-resisting welding in the metal surface.

1) Ceramic, metal lapping, and polishing applications

2) Slicing of silicon carbide wafers

3) Rock and stone polishing and engraving

4) Slicing, lapping,and polishing glass and germanium wafers

5) Lapping of piston rings and gears

6) Grinding of nonferrous materials

7) Finishing tough and hard materials

8) Bonded abrasive tool applications

9) Glass etching and glass carving industries

![]()

Why choose us?

FAQ

Q1.What is your advantage ?

A:We have the best factory to produce for you,could guarantee the price is the most competitive. BEGUN carbide was recognized by market, it widely used for Chinese big project,such as subway,high speed rail,tunnel,mining and so on.At the same time,many big projects of the South africa,America,European and Austria also choose our carbide.

Q2. What is your terms of payment?

A: T/T 30% as deposit, and 70% balance before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q3.Could you offer OEM and ODM service?

A:That is ok ,we have more than 5 years experience in OEM service.professional R&D department is ready to design products to fit your specifications,they can offer the professional advice and CAD drawings(3D) for you!

Q4. How about your delivery time?

A: Lead time as fast as 7-15 days!

Q5. What is the MOQ ?

A.No MOQ for our existing stock,for special size,MOQ is 5 KGS.

Q6. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost

Q7. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery.Our production is based on ISO9001,we have more than 10 years experience of QC team and strictly quality control system in our production process.

Q8. What about the package?

A.It can make as the you need and depend on the products shapes. Generally, we can provide iron drum, carton, wooden case, and bag packages.

Q9: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Customer Notice

To save your value time, please inform us of the following information:

1. Grade

2. Type/Dimension/Clear Drawing

3. Available tolerance

4. Order quantity

5. Blanks or finished products

6. If you have any special requirements of the products, pls send us in advance. We will satisfy you as much as we can.

Contact

Whatsapp/wechat/phone:008618593402651

Facebook:Xiao Aimee

zhuzhou mingri cemented carbide co. ltd

Email:mr009@mrcarbide.com