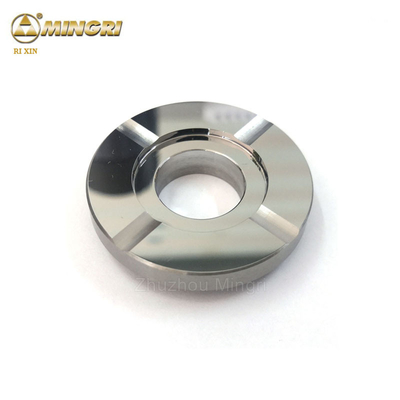

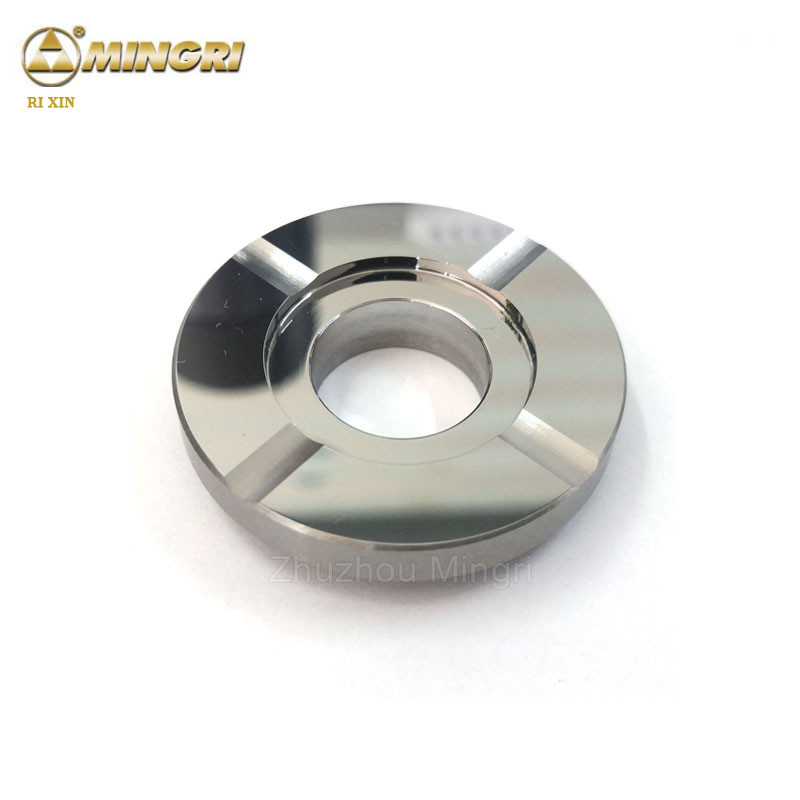

OEM High Wear Resistant Cemented Tungsten Carbide Shaft Bearing Sleeve Bushing For Oil Gas Mining Industry

Product Details:

| Place of Origin: | China |

| Brand Name: | Rixin |

| Certification: | ISO 9001:2008 |

| Model Number: | YG8 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1KG |

|---|---|

| Packaging Details: | Cartons |

| Delivery Time: | 7-15 days |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 50+tons+per month |

|

Detail Information |

|||

| Product Name: | Tungsten Carbide Shaft Bearing | Material: | Tungsten Carbide |

|---|---|---|---|

| Application: | For Water / Oil Pump | Grade: | YG6X,YN8,YG10,YL10.2,YG20, YG8,etc |

| Surface Finish: | Polished And Unpolished | Pacakge: | Standard Cartons |

| Usage: | Oil Industries | Key Words: | Tungsten Carbide Shaft Bearing |

| High Light: | Cemented Shaft Bearing Sleeve,Tungsten Carbide Shaft Bearing Sleeve,OEM Shaft Bearing Sleeve |

||

Product Description

OEM Customized High Wear-Resistant Cemented Tungsten Carbide Shaft Bearing Sleeve Bushing for Oil Gas Mining Industry

Description of tungsten carbide sleeve

Tungsten carbide bushing set up by virgin tungsten carbide material.

It’s shows high hardness and bending strength.

It has superior performance on resisting abrasion and corrosion, which is widely used in many industries.

Tungsten carbide bushing are often made with high accuracy, and owing to their perfect finish, precise dimension, durability and corrosion resistance.

These are highly appreciated by the clients at home and aboard.

In addition, differ from the various of application environment. There are several types of Tungsten carbide bushing.

Most of the specifications are all customized. Zhuzhou Mingri has backed by rich industry knowledge and production experience of various Tungsten carbide bushing.

This can produce various of Tungsten carbide bushing based on specific design.

|

Product name

|

tungsten carbide sleeve |

|

Material

|

100% virgin tungsten carbide |

|

Color

|

grey |

| Standard |

ISO 9001:2008

|

| Grade |

YG6X YG10X YG8 YG15 / YN8 YN11 ect

|

| Dimensions(mm) |

OD(10~ 300) x ID(3 ~ 260) x H(8-150) |

| Grain size(um) |

0.6/0.8/1.2/2/4

|

Feature of tungsten carbide sleeve

1. High hard resistance

2. High corrosion resistance

3. Pressured resistance

4. Wear resistance

5. High bending strength

1) Tungsten carbide bushing applications is wide, which is a device to protect a class of components. It is in the actual work and the role and purpose of its application environment have a great relationship.

2) Valve applications, bushings be installed in the valve stem cap trap, in order to reduce the valve leakage, to seal; bearing applications, the use of bush to reduce wear between the bearing and the shaft seat, avoid the gap between the shaft and the hole increases and so on.

3) Tungsten carbide bushing production and processing of high-strength, can withstand prolonged load, with high chemical stability, alkali, alcohol, hydrocarbons, acid, oil, detergent, water (sea water), and has no smell , non-toxic, tasteless, non-rust characteristics.

4) its widely used in petrochemical industry for submerged oil pump, slurry pump, water pump, Centrifugal Pump,etc.

![]()

![]()