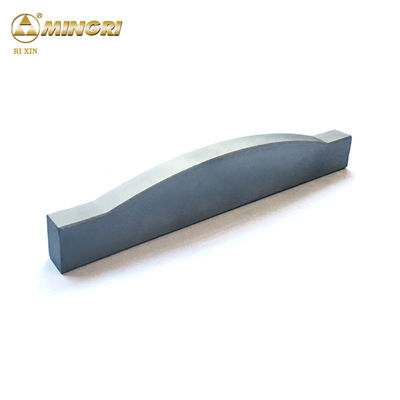

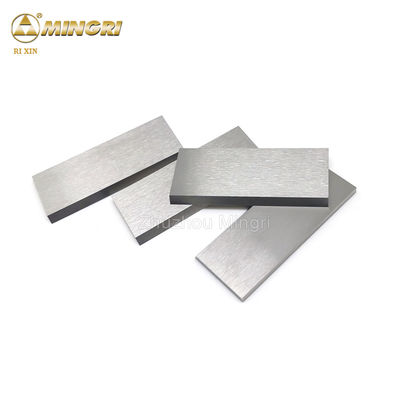

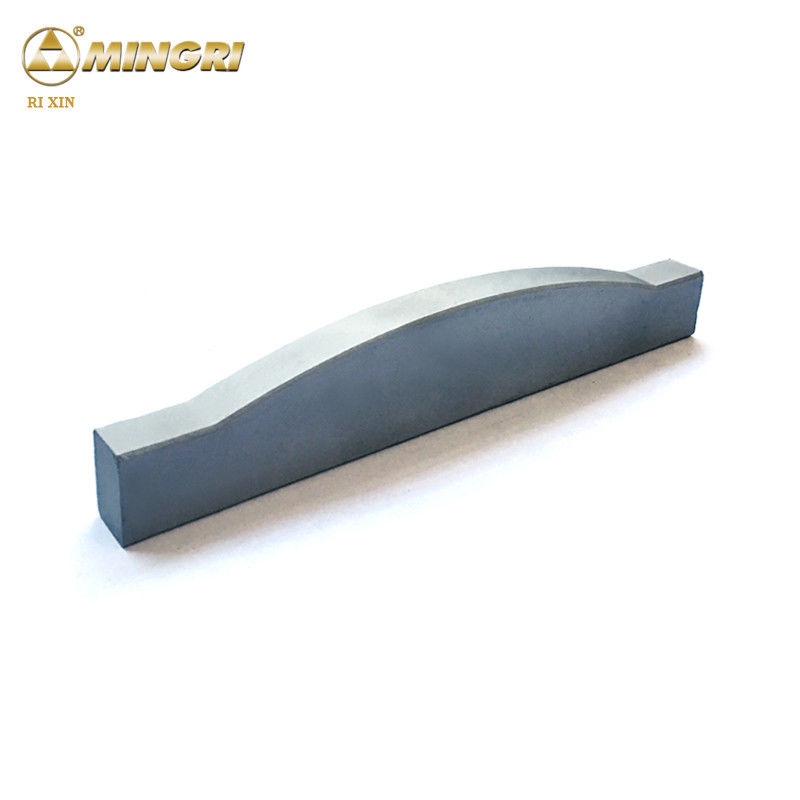

Raw material K10 Tungsten Power Carbide Square Bar Vsi Strip for crusher stone

Product Details:

| Place of Origin: | Hunan ,China |

| Brand Name: | RIXIN |

| Certification: | ISO9001:2008,ISO9001:14001 |

| Model Number: | cemented carbide strips-02 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1kg |

|---|---|

| Price: | 50-70$ |

| Packaging Details: | paper, then paper boxes, then exported wooden cartons or paper cases,or packed as customers'requirement. |

| Delivery Time: | 7-20 business days |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 50tons/month |

|

Detail Information |

|||

| Application: | Crushing Stoneor As Cutting Tools | Material: | Vrian Raw Material |

|---|---|---|---|

| Service: | OEM & ODM | Trial Order: | Acceptable |

| Grade: | K10 K20 K30 YG6 YG8 YG11C | Payment: | L/C, T/T Etc |

| Color: | Gray | ||

| Highlight: | tungsten carbide bar,tungsten carbide block,Tungsten Powder Carbide Square Bar |

||

Product Description

Grades of finished hard alloy k10 carbide strip

| Properties and applications of carbide for strips | ||||||||

| Grade | Density | T.R.S MPa |

Hardness HRA |

Performance & application recommended | ||||

| YM6 | 14.9 | 2150 | 90 |

Good wear resistance, used for hard wood, used for processing original wood, aluminum section bar, brass rod and cast iron. |

||||

| YM6A | 14.9 | 1860 | 92 |

Has wear resistance higher than YG6, used for processing hard wood, original wood, aluminum section bar, brass rod and cast iron. |

||||

| YM8 | 14.7 | 2320 | 89.5 |

Wear and percussion resistance , used for processing hard wood, soft wood, ferrous and non-ferrous. |

||||

| YM2T | 14.5 | 2350 | 92 |

Fine carbide, High wear resistance, high bending strength, high resistance to bonding, high thermal strength. Machining of refractory alloys, stainless steel and high manganese steel, etc. |

||||

| YM25 | 14.5 | 2150 | 92.2 |

Wear resistance and strength comparatively higher, suitable for processing cast iron, non-ferrous,metal and non-metallid materials. |

||||

| Other grades of strips may be offered according to customers' requirement. | ||||||||

![]()

Why choose us?

1.Zhuzhou Mingri has the richest molds stock of cold forging dies.

2.Over 20 years of stable relationship with our customers.

3.The most advanced tooling house.

4.The largest production capacity and fastest delivery.

5.The most reliable testing machines for all specifications.

6.The best and reliable after service.

| Packing | Carton and inner plastic box. |

| Shipping | UPS,TNT,EMS,Fedex,DHL,or as you request. |

![]()

FAQ

Q1: Shall we get free sample ?

A1:Mostly new customer needs pay the sample fees at first time .

Q2:When will you send out the goods ?

A2:Normally it takes about 7-20 days.it depends on the quantity and specific situation

Q3:Do you provide customized products ?

A3:Yes,of course.we can do many non-standard products for you .we also open mould department in our factory.we can make new mould for you soon

Q4:Should we pay mould fees for you ?

A4:If the mould we have,you needn’t pay it,if it is customized tungsten carbide parts.normally need pay the new mould.we will offer you the reasonable price.

Q5:Do you have quality-control system?

A5:Yes,we have,we have a professional quality-control department who has a strong quality management control system.

Q6:What’s the payment way?

A6:Via T/T,L/C,western union and so on

Q7:Are all raw materials ?

A7:We have original raw material and recycle material.it depends on the grade that customer need.

Q8:If get the goods,there is some problem with it,how could you solve it ?

A8:When we know the quality problem,firstly we will report to our quality control department.They will analysis it and make a solution to you.We’ll try to avoid the problem any more