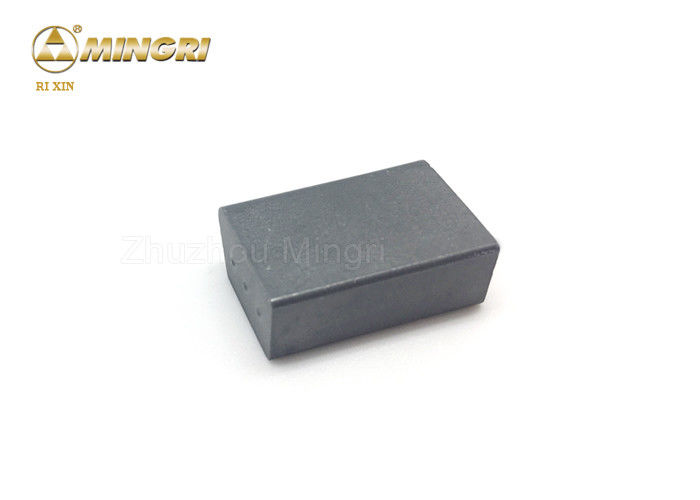

Tungsten Carbide Snow Plow Bits Hard Alloy Tool Part High Wear Resistance

Product Details:

| Place of Origin: | China |

| Brand Name: | rixin |

| Certification: | CE/ISO9001:2015 |

| Model Number: | carbide inserts |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1kg |

|---|---|

| Price: | 32.68$/kg-45.59$/kg |

| Packaging Details: | step 1, wrapped carbide stud pins in paper to avoid carbide stud pins be broken step 2, put the carbide stud pins in inner small carton box step 3, put the inner box into outer carton and fill the carton with foamed plastic step 4, wrap the carton with |

| Delivery Time: | 7-20 business days |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 50 tons/month |

|

Detail Information |

|||

| Material: | Tungsten Carbide,100% Virgin Raw Material | Grade: | MR20T |

|---|---|---|---|

| Density: | 13.1 | Hardness: | 88.2 |

| Strength: | 2590 | Size: | 25.15*9.27*19.05mm NR |

| Application: | Snow Plow | Color: | Gray |

| Package: | Paper Box | Stock: | Produce Directly |

| Packing: | In One Carton Or As You Wish | ||

| Highlight: | carbide tool inserts,carbide milling inserts |

||

Product Description

High Wear Resistance Tungsten Carbide Snow Plow Bits hard alloy tool part

Factory introduction

Zhuzhou Mingri Cemented Carbide Co.,Ltd is opening new and bigger markets, we have many good show as below:

1,We did some Trade Assurance order on alibaba, keep customer can get good quality products and efficient delivery time.

2, Mingri overseas team attend many different country fair show each year, like Germany, Russia, Brazil, Australia, India, etc, and got good feedback for the Good impacting Tungsten Carbide mining insert tips for drilling hard materials

Snow plow inserts are made by hard compound refractory metal shovel the snow and the bonding metal by powder metallurgy technology made of an alloy material. Cemented carbide snow plow inserts with high hardness, wear resistance, good strength and toughness, heat resistance, corrosion resistance and a series of excellent properties, especially its high hardness and wear resistance, even at 500 ℃ temperature basic remains the same, there are still very high hardness at 1000 ℃. Hard alloy are widely used as a cutting tool material, such as turning, milling, planing tool, drilling, boring cutter, etc., used for cutting cast iron, non-ferrous metal, plastic, chemical fiber, graphite, glass, stone and ordinary steel, can also be used for cutting heat resistant steel, stainless steel, high manganese steel, tool steel and other hard processing material. New type of hard now hundreds of times of the cutting speed is equal to the carbon steel.

Grade of Good abrasion resistance for Good impacting Tungsten Carbide mining insert tips for drilling hard materials

BladeRunner extended wear life blades are premium tungsten carbide bits designed to extend the wear life of the edge, reducing the need for blade changes.

These high-strength tungsten carbide bits will bolt to virtually any snow plow or motor grader and are to be used where the customer requires longer blade life.

![]()

Production Process

To ensure the quality and the requirements of the drawings can be met before mass production

1st:, Start to prepare the RTP powder as per customer’s requirement with our wet-grinding machine

2nd, Before mass production, do a trial pressing and sintering using mould,

3rd, Check the appearances and the sizes of the samples with micrometer, projectors etc.

Test process

1st,Mass production, press the raw materials to shape blanks,

Notes: all carbide stud pins blanks must be passed by semi finished inspection

2nd,Sinter blanks to finish (HIP) and finished products inspection,

Notes:10 sets of vacuum sintering furnace and 2set of HIP in the factory ensure the best quality and production capacity.

3rd,Cleaning/tumbling to make the carbide stud pins clean and nice surface.

Feel free to contact aimee if any needs:

Whatsapp/wechat/phone:008618593402651

Facebook:Xiao Aimee

zhuzhou mingri cemented carbide co. ltd

Email:mr009@mrcarbide.com