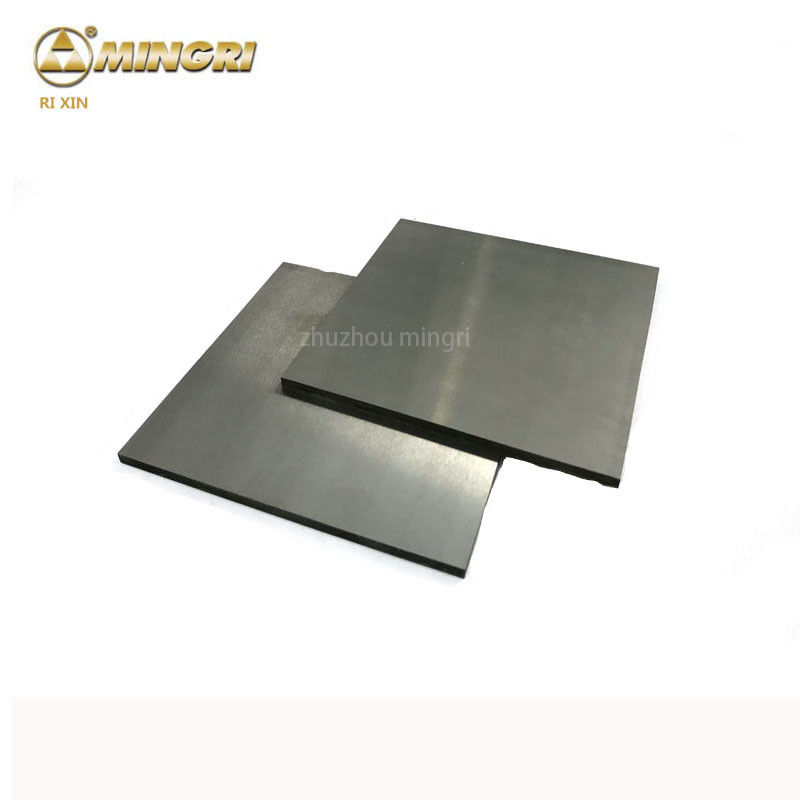

Wear Resistance HIP Sintering Tungsten Plate , Cemented Carbide Plate Blocks Bars

Product Details:

| Place of Origin: | Zhuzhou,Hunan,China |

| Brand Name: | Ri Xin |

| Certification: | ISO9001:2015 ISO14001:2015 |

| Model Number: | As per customer request |

Payment & Shipping Terms:

| Minimum Order Quantity: | 5KG |

|---|---|

| Price: | As per technical requirements |

| Packaging Details: | First in small cartons filled with cotton, then in bigger cartons.Wood carton recommended |

| Delivery Time: | 10-20 days after receipt of payment |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union |

| Supply Ability: | 50 tons per month |

|

Detail Information |

|||

| Features: | High Hardness,good Impact-resistance | Material: | WC,Cobalt |

|---|---|---|---|

| Grades: | YG6A,YG8,YG15,YG20,YG13X,YS2T | Service: | OEM,Customized Manufacturing |

| Application: | Dies Machining,Blades Machining | Density: | 13.5-14.85g/cm³ |

| Hardness: | 85.5-92HRA | Strength: | 2000-3200 T.R.S |

| Highlight: | tungsten carbide wear plate,tungsten carbide sheet |

||

Product Description

wear resistance zhuzhou mingri tungsten cemented carbide plates blocks bars

Descriptions:

Item name: Tungsten carbide plate

Grade:YG6, YG8, YG11, YG15, YG20, YG13X, YM2T,etc

Sizes: Length:10-200mm, width:10-200mm, Thickness: 5-50mm,

We also provide OEM size and customized.

Grades and applications:

| Grade | Properties & Applications | Approx Grades in China | |||

| Density | T.R.S | Hardness | |||

| g/cm3 | MPα | HRA | |||

| YM6A | 14.9 | 2000 | 92.5 | Fine grain alloy, good wear resistance. It is suitable for manufacturing forming cutter, wear-resistant parts etc. | YG6A |

| YM8 | 14.7 | 2800 | 89.8 | High bending strength, wear resistance lower than YM6A, suitable for manufacturing forming cutter, wear-resistant parts etc. | YG8 |

| YM11 | 14.4 | 2900 | 88.5 | High bending strength, wear resistance lower than YM6A, suitable for manufacturing forming cutter, wear-resistant parts etc. | YG11 |

| YM15 | 14 | 3000 | 87 | Suitable for manufacturing punching dies, wear-resistant parts. | YG15 |

| YM20 | 13.5 | 2800 | 85.5 | High bending strength, suitable for manufacturing progressive dies and other punching dies. | YG20 |

| YM13X | 14.2 | 3200 | 90.0 | High bending strength, suitable for manufacturing progressive dies and other punching dies. | YG13X |

Product types of Wear parts hard alloy widia cemented tungsten carbide board block bar plates

Product types of Wear parts hard alloy widia cemented tungsten carbide board block bar plates

| L | W | S |

| 200 | 200 | 10-45 |

| 150 | 150 | 10-45 |

| 150 | 130 | 10-45 |

| 150 | 100 | 10-45 |

| 150 | 80 | 10-45 |

| 120 | 120 | 10-45 |

| 100 | 100 | 10-50 |

| 100 | 50 | 10-50 |

| 100 | 45 | 10-50 |

| 80 | 55 | 10-50 |

| 80 | 40 | 10-40 |

| 70 | 35 | 5-40 |

| 45 | 25 | 5-20 |

| 35 | 19 | 5-20 |

| 20 | 20 | 5-20 |

| 18 | 13 | 5-20 |

| ... | ... | ... |

All the products must be inspected strictly with the ultrasonic and only those haven't any harm such as pore can be shipped out. High density, high wear & impact resistance, which lead them a long lifetime.

![]()

Product Description of High density hard alloy wear resistant cemented tungsten carbide plates

---- Making connectors in electron industry, IC industry and semiconductor

---- Heat-resistant parts, wear-resistance parts, anti-shielding parts, anti-corrosion parts.

---- Making progressive press tools and progressive dies of high velocity ram machine.

---- Armature, stator, LED lead frame, EI silicon steel sheet and punching mould for hardware and standard parts.

Our advantages:

1.Strong R&D team. Professional engineers serve for clients, recommend product and grades as per your applications. We also offer after-sale service.

2. Strong Mould R&D team. We support product customization as per your requirements, ensure high working efficiency and product quality.

3. Successful cooperation case: We cooperate with clients in domestic and abroad, and get good feedback from them.

Feel free to contact me if any needs:

Whatsapp/wechat/phone:008618593402651

Facebook:Xiao Aimee

zhuzhou mingri cemented carbide co. ltd

Email:mr009@mrcarbide.com