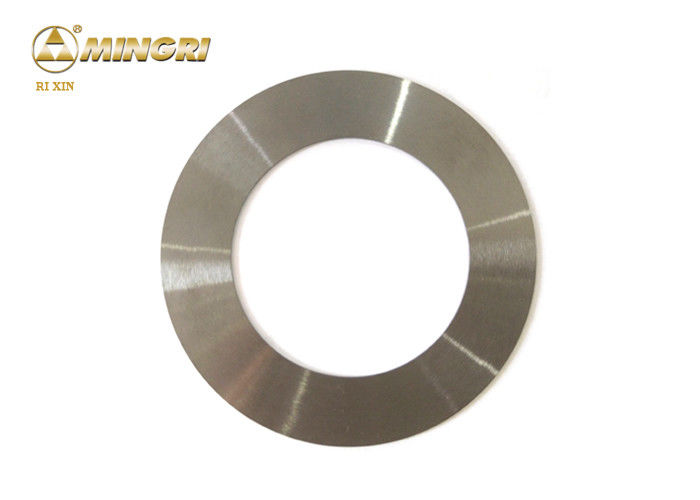

Cemented Carbide Blade Cutting Non Ferrous Foil round rings raw material

Product Details:

| Place of Origin: | ZHUZHOU,HUNAN,CHINA |

| Brand Name: | RI XIN |

| Certification: | ISO9001:2008 ISO14001:2004 |

| Model Number: | K10,K20,K30,K05,K40 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1KG |

|---|---|

| Price: | 32.68$/kg-68.59$/kg |

| Packaging Details: | First in small cartons filled with cotton, then in bigger cartons. |

| Delivery Time: | 7-20 days |

| Payment Terms: | L/C, D/A, D/P, T/T, L/C, T/T, Western Union |

| Supply Ability: | 50 Tons per month |

|

Detail Information |

|||

| Features: | High Hardness,Good Impact Resistance,High Wear Resistance | Material: | WC,Cobalt |

|---|---|---|---|

| Grade: | SH6A,SH10A,SH25,SH30,SH35 | Application: | Metal And Wood Cutting |

| Surface Treatment: | Polishing,sand-blasting | Size: | Customer Requst |

| Hardness: | 90.5 HRA | TRS: | 3200 |

| Character: | High Precision And Wear Resistance | Density: | 14.1 |

| High Light: | tungsten carbide blade,carbide rotary cutter |

||

Product Description

Cemented Carbide Blade Cutting Non Ferrous Foil round rings raw material

1, Focusing on manufacturing tungsten carbide products over 18 years.

2, Specialist manufacturer equipped with advanced processing machines and over160 technicians.

3, Over 50 tons/month productivity to assure sustainable supply of products

4, Owing mould workshop to design & produce moulds for nonstandard products, and with mould

stocks over 10 thousand sets for different products.

5, Full ability to accept OEM & ODM orders.

6, Stringent quality control and quality consistency.

7, Professional mechanical & chemical inspecting labs to control the quality of raw material and inspect physical & mechanical properties of finished products.

![]()

Applications:

Tungsten carbide disc cutter is suitable for semifinishing the chilled cast iron, nonferrous

metal and its alloy. It is also suitable for semifinishing and finishing the hardened steel

and alloy steel.

Grade and Applications:

| Grade |

Density g/cm3 |

T.R.S MPα |

Hardness HRA |

Properties & Applications |

Approx Grades in China |

ISO |

| SH6A | 14.9 | 1850 | 92 |

Fine grain alloy, good wear resistance. It is suitable for machining the chilled cast iron, nonferrous metal and its alloy. It is also suitable for semifinishing and finishing the hardened steel and alloy steel. |

YG6A | K10 |

| SH10A | 14.8 | 2450 | 90.5 |

High wear resistance and bending strength, suitable for disc cutters in electronics industry. |

_ | K20-K30 |

| SH25 | 14.8 | 2200 | 89.5 |

Higher strength, impact and shock resistance than SH6A, but lower in wear resistance and cutting speed. It is suitable for rough machining cast iron, nonferrous metal and its alloy as well as non metallic materials at low cutting speed. |

YG8 | K20 |

| SH30 | 14.7 | 2320 | 89.5 |

Higher strength, impact and shock resistance than SH25, but lower in wear resistance and cutting speed. It is suitable for rough machining cast iron, nonferrous metal and its alloy as well as non metallic materials at low cutting speed. |

YG8 | K20 |

| SH35 | 14.5 | 2200 | 91 |

Fine grain alloy with good wear resistance. It is suitable for machining hard wood, plywood,PCB, PVC and metals. |

YG10X | K10-K20 |

| SH40 | 14.5 | 2480 | 92 |

Fine grade alloy with high wear resistance, bending strength, bonding resistance and thermal strength. It is suitable for machining plywood, PCB, PVC,refractory alloys, stainless steel and high manganese steel etc. |

YS2T | K10-K20 |

| SH50 | 14.3 | 2420 | 90 |

Moderate wear resistance and bending strength ,suitable for machining steel alloy etc. |

_ |

K20-K30

|

Common size:OD*ID*T(mm)

φ68/72/76*φ46*0.5/1

φ60*φ40*5

φ98*φ66*0.7

φ80*φ55*5

φ100*φ65*0.7

Characteristic :The blade has good appearance,high consistency and wear resisitance,the cutting edge can pass the inspection of enlarging 200 times without chips on it.Guranteed cutting quality,long working life,also the frequency of replacing blades is very low with high cost performance

![]()

1, Soon after the order is confirmed, tungsten carbide steel knife products will start to prepare the RTP powder as per customer’s requirement with our wet-grinding machine

2, Before mass production, we need to do a trial pressing and sintering using every mould, and we check the appearances and the sizes of tungsten carbide steel knife samples with micrometer, projectors etc. to ensure that the requirements of the drawings can be met before batch production

3, Bulk production ,press the raw materials to shape blanks,and all tungsten carbide steel knife blanks must be passed by semi finished inspection,

4, Then sinter blanks to finish (HIP) and finished products inspection, we have 10 sets of vacuum sintering furnace and 2 sets of HIP in the factory ensure the best quality and production capacity.

![]()

![]()

Packing and delivery:

1. Rubber protector for cutting edges, blade in bubble pack, carton case.

Max 10 pcs blades in one carton case

2. Exterior packaging: carton or wooden case

3. Other packaging upon your request

4. We also have the professional agents shipping our products to the customers.