High Hardness YG6 YG6A WC Cobalt Tungsten Carbide Block For Machining Hard Wood

Product Details:

| Place of Origin: | China |

| Brand Name: | RI XIN |

| Certification: | ISO14001,ISO9001 |

| Model Number: | YG6,YG6A,YG8,YS2T,YS25,YL10.2 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 10KG |

|---|---|

| Price: | USD+49~69+KG |

| Packaging Details: | paper, then paper boxes, then exported wooden cartons or paper cases,or packed as customers'requirement. |

| Delivery Time: | 7 to 10 working days depending on the order quantity and requirements |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union |

| Supply Ability: | 50 Tons per month |

|

Detail Information |

|||

| Features: | Good Wear/impact Resistance | Product Name: | High Hardness YG6 YG6A WC Cobalt Tungsten Carbide Block For Machining Hard Wood |

|---|---|---|---|

| Grade: | YG6,YG6A,YG8,YS2T, | Application: | Machinng Refractory Alloys,stainless Steel,high Manganese Steel |

| Surface Treatment: | Grinding,Sand-blasting,Polishing | Material: | Tungsten Carbide, Cemented Carbide |

| Highlight: | tungsten carbide block,tungsten carbide plate |

||

Product Description

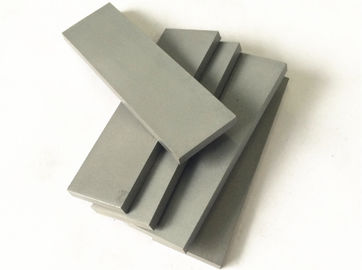

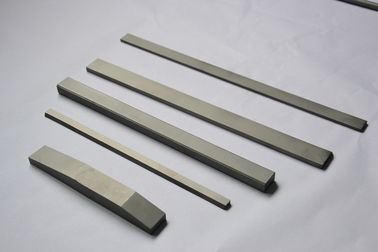

Tungsten Carbide Strips For Hard wood Machining,YG6,YS2T,WC,Cobalt

High Hardness Tungsten Carbide for Machining hard wood,YG6,YG6A,WC,Cobalt

Description:

- HIP sintering,have good wear resistance,good impact resistance,high bending strength.

- Widely used for producing various of motors,electronic progressive and punching dies.

- Strip products can be used for machining refractory alloy,hard wood,aluminum section bar,brass rod and cast iron.

- Available OEM and ODM services.

Grades and applications:

| Grade |

Density g/cm³ |

T.R.S Mpα |

Hardness HRA |

Performance and application |

| YG6 | 14.9 | 2400 | 90.5 | Good wear resistance,suitable for machining hard wood,raw wood,aluminum section bar,brass rod and cast iron. |

| YG6A | 14.9 | 2000 | 92.5 | Better Wear resistance than YG6,suitable for machining hard wood,raw wood,aluminum section bar,brass rod and cast iron |

| YG8 | 14.7 | 2800 | 89.8 | High wear and impact resistance,suitable for machining dry wood,soft wood and non-ferrous metal section bar. |

| YS25 | 13.0 | 2200 | 91.0 | Wear resistance and strength comparatively higher,suitable for machining cast iron,non-ferrous metal and non-metallid materials. |

| YL10.2 | 14.4 | 3000 | 91.8 | Wear resistance and strength comparatively higher,suitable for machining cast iron,non-ferrous metal and non-metallid materials. |

| YS2T | 14.2 | 2400 | 92.0 |

Fine grain alloy,with high wear reistance,bending strength,bonding resistance and thermal strength.It’s suitable for machinng refractory alloys,stainless steel,high manganese steel and etc. |

Other grades and size can be offered as per customer requirements.

![]()

Package:

All of our packages are kind of inner package to ensure the products won’t get damaged each other.

First,packed in small box fixed with cotton or foam.Then packed in a big carton or use wood carton box if it is needed.

Packed as per client request.

Our advantages:

1.Strong R&D team. Professional engineers serve for clients, recommend product and grades as per your applications. We also offer after-sale service.

2. Strong Mould R&D team. We support product customization as per requirements, ensure high working efficiency with good quality.

3. Successful cooperation case: We cooperate with clients in domestic and abroad, and get good feedback from them.

![]()

![]()