Cemented Carbide Cold Punching Mould for nut forming,YG11,YG15,WC,Cobalt

Product Details:

| Place of Origin: | China |

| Brand Name: | RI XIN |

| Certification: | ISO9001,ISO14001 |

| Model Number: | YG11,YG15,YG20,YG16C,GT55 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 5 KG |

|---|---|

| Price: | Varies according to the grade,size and qty |

| Packaging Details: | First packed in small carton,then in a big carton.Wood carton or metal barrel recommended. |

| Delivery Time: | 7-20 days |

| Supply Ability: | 50 Tons per month |

|

Detail Information |

|||

| Features: | High Hardness,Good Impact/wear Resistance | Material: | WC,Cobalt |

|---|---|---|---|

| Grade: | YG11,YG15,YG20,YG16C,YG22C,YG25C,GT55 | Application: | Cold Heading/Forging Die,Valve Seat |

| Highlight: | tungsten carbide tools,tungsten carbide tooling |

||

Product Description

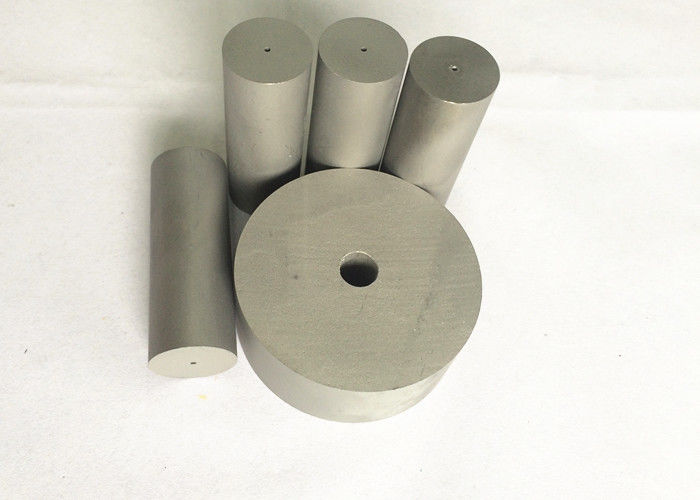

Cemented Carbide Cold Punching Mould ,Tungsten carbide cold heading dies

CUSTOMIZED TUNGSTEN CARBIDE COLD HEADING DIES:

YG11,YG15,YG20,YG16C,YG18C,YG20C,YG22C,YG25C,GT55

We provide OEM,ODM service as per Customer request and you also can choose the grade and decide the size of moulds.

Description:

1.Widely used as cold punching mould and forging mould.

2.Non-standard sizes of carbide pellets based on customer requests.

3.All carbide pellets are strictly inspected by ultrasonic flaw detector to avoid blowholes or cracks to ensure the quality.

4.Material:100%Virgin material with submicron grain size.

5.High wear resistance,high hardness and impact toughness.

6.We can provide blank or deep finished products with precision grinding and polishing.

Our advantages:

1.Strong R&D team. Professional engineers serve for clients, recommending product and grades as per your applications. We also offer after-sale service.

2. Strong Mould R&D team. We support products customization as per requirements, and ensure high working efficiency and product quality.

3. Successful cooperation case: We cooperate with clients in domestic and abroad, and get good feedback from them.

Grade:

| Grade | Density g/cm3 |

T.R.S MPα |

Hardness HRA |

Properties & Applications | Approx Grades in China |

| A | 13.5 | 3000 | 83.5 | Good wear resistance and bending strength. It is often preferred by nut forming dies and high impact-resistantance dies. | — |

| YM11 | 14.4 | 2420 | 88.5 | Forming or stamping dies for metal powders and nonmetal powders. | YG11 |

| YM15 | 14.0 | 2500 | 87.5 | It is suitable for drawing steel tubes and rods under high compression ratio, manufactuing upsetting, punching and forging tools under large stress. | YG15 |

| YM20 | 13.5 | 2800 | 85.5 | It is suitable for manufacturing punching dies for watch parts, leaf spring of musical instruments, battery jars, small size of steel balls, screws, screw caps, etc. | YG20 |

| ML32 | 13.9 | 2750 | 85.5 | It is suitable for impact-resistantance forging dies. | YG16C |

| ML36 | 13.7 | 2800 | 84.5 | It is suitable for impact-resistant forging dies, hot-forging dies and finishing rollers. | YG18C |

| ML40 | 13.5 | 2850 | 83.5 | It is suitable for wear resistantance or impact resistantance dies. | YG20C ZL40.2 |

| ML50 | 13.3 | 2900 | 83.0 | It is suitable for nut forming dies and high impact-resistant dies. | YG22C ZL40.5 |

| ML60 | 13.1 | 2950 | 82.5 | It is suitable for stainless screw dies and semifinishing rollers. | YG25C ZL40B |

| ML80 | 13.1 | 3050 | 83.4 | It is suitable for screw cap forming dies with high strength ( highest impact-resistantance forging dies). | YG25C GT55 |

| Other grades of cemented carbide blanks for cold-forging dies may be offered as per customer requirements | |||||

![]()

![]()

![]()

![]()

![]()

![]()